A preparation method of a photoelectric conversion laminate and a method for testing its electrical properties

A photoelectric conversion layer and electrical performance testing technology, applied in the field of solar cells, can solve the problems of not being able to provide guidance for new product development, affecting electrical performance test results, and unstable test values, saving manpower and material resources, high repeatability, Test the effect of numerical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

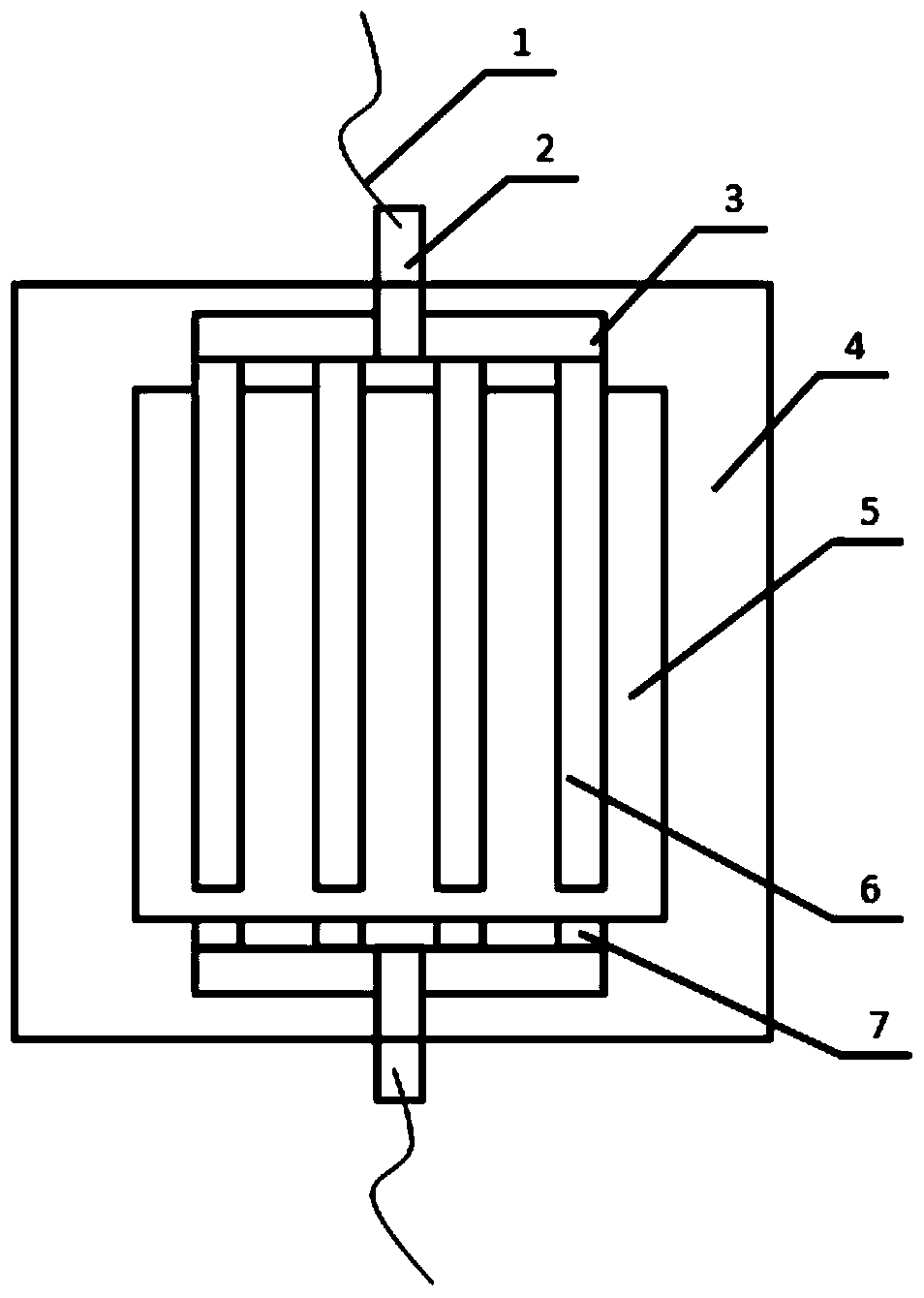

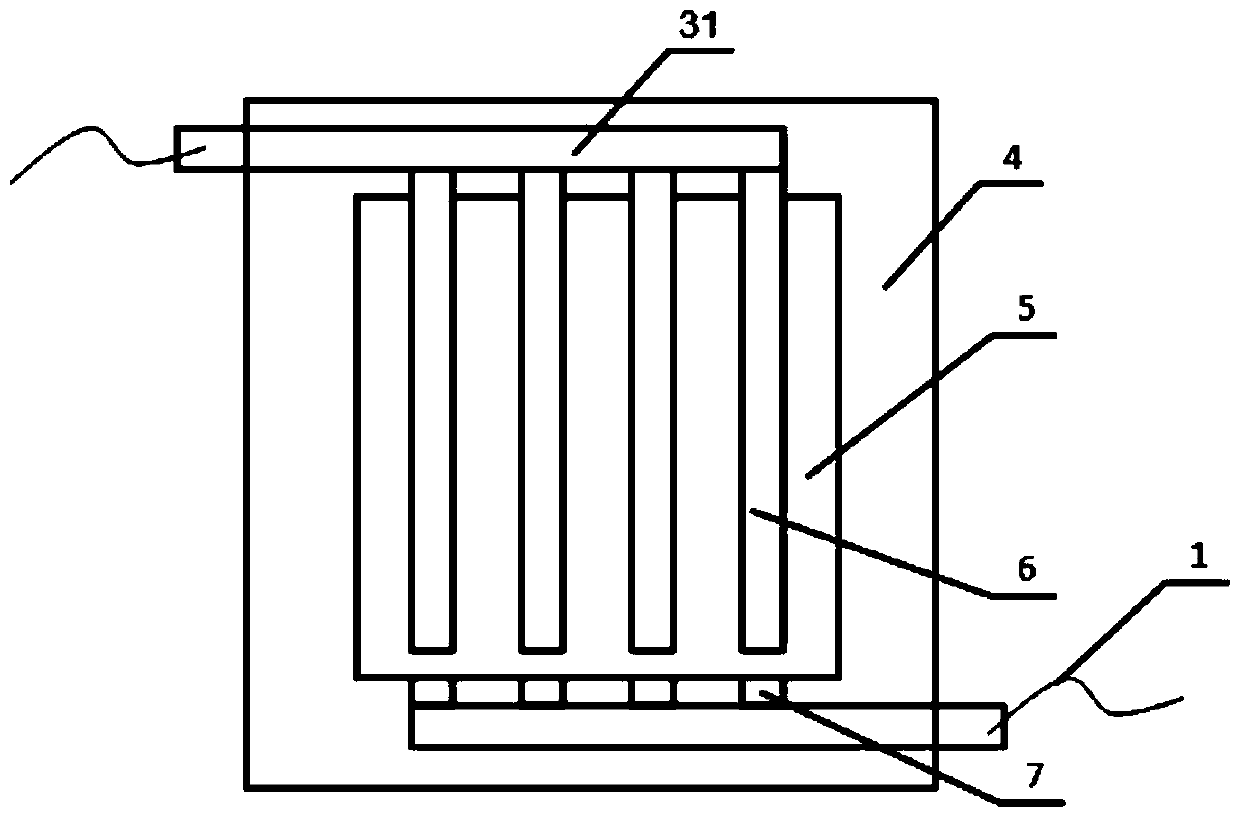

[0055] see figure 1 Shown, a kind of preparation method of photoelectric conversion laminate, is characterized in that, comprises the steps:

[0056] (1) The anode of the photoelectric conversion device is connected with the positive connection wire 6, and the negative electrode of the photoelectric conversion device is connected with the negative connection wire 7;

[0057] (2) When the number of photoelectric conversion devices is one piece, the positive connection wires of the photoelectric conversion devices are connected together by using the first bus wire, the first bus wire is located at the end of the positive connection wire, and the length of the first bus wire It is equal to the distance between the two outermost positive connecting wires in the photoelectric conversion device; the negative connecting wires of the photoelectric conversion device are connected together by the second bus wire, and the second bus wire is located at the end of the negative connecting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com