Method for manufacturing low-temperature co-fired ceramic substrate green tape of photolithographic film technology printed circuit

A technology of low-temperature co-fired ceramics and production methods, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve problems such as electronic product damage, process yield reduction, and cutting blade damage, and achieve the goal of reducing damage The effect of increasing production rate, improving production yield, and reducing frictional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The low temperature co-fired ceramic substrate, its manufacturing method and semiconductor packaging device according to preferred embodiments of the present invention will be described below with reference to relevant figures.

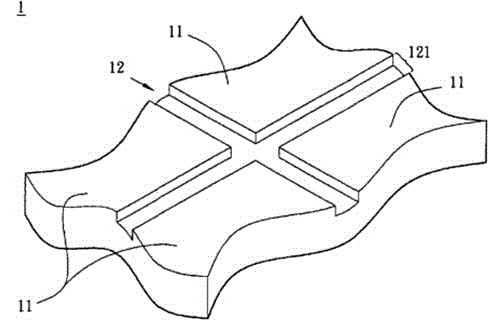

[0032] Please refer to figure 1 As shown, a low temperature co-fired ceramic substrate 1 according to a preferred embodiment of the present invention includes a plurality of substrate units II and at least one cutting pattern 12 . In this embodiment, four substrate units 11 are taken as an example, but it is not used to limit the number of substrate units II. Users can increase or decrease the number of substrate units I1 according to their needs.

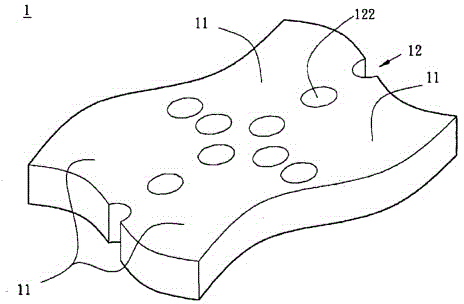

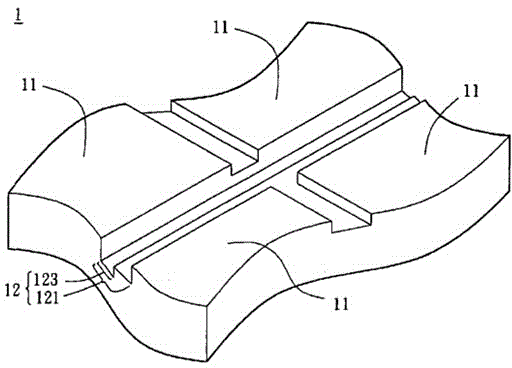

[0033] The cutting pattern 12 is disposed between two adjacent substrate units 11, so that the cutting device can perform cutting action along the cutting pattern 12. Wherein, cutting pattern 12 can be as figure 1 As shown, it is a groove 121, or as figure 2 As shown, it is a multi-hole 122,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com