Anti-dust mortar composition

A composition, mortar technology, applied in the field of building products, which can solve the problems of hydrocarbon-based oil inhalation, major hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

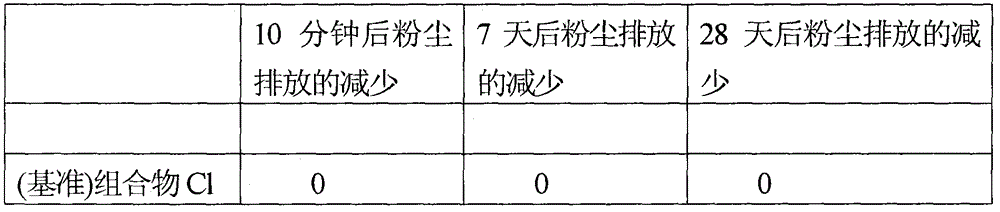

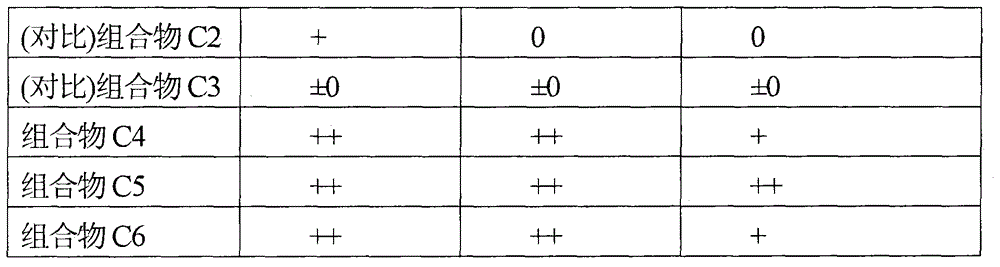

[0039] Dry mortar composition C1 was prepared by mixing the following components (the given percentages correspond to mass percentages):

[0040] 47% CEM Type I Portland Cement

[0041] 50% sand with particle size less than 1mm

[0042] 3% Vinnapas N 5010RE (Wacker) Latex

[0043] Starting from this reference composition C1, compositions C2 to C6 were prepared with the addition of different organic carbonates which are liquid at normal temperatures and have a purity greater than 95%, either alone or mixed with mineral oil:

[0044] • 1% propylene carbonate, relative to the total weight of composition C1. Composition C2 is thus obtained.

[0045] • 0.2% mineral oil Sivano 1 (from Cogelsa), relative to the total weight of composition C1. Composition C3 is thus obtained.

[0046] • 1% diethylhexyl carbonate, relative to the total weight of composition C1. Composition C4 according to the invention is thus obtained.

[0047] • 0.8% diethylhexyl carbonate and 0.2% Sivano 1 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com