Copolyester and polyester fibers containing it

A technology of co-polyester and co-polymerization, which is applied in the field of polyester fiber, can solve the problems of reduced light resistance, reduced strength over time, and stick-slip, etc., and achieves the effect of high hygroscopicity and high hygroscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

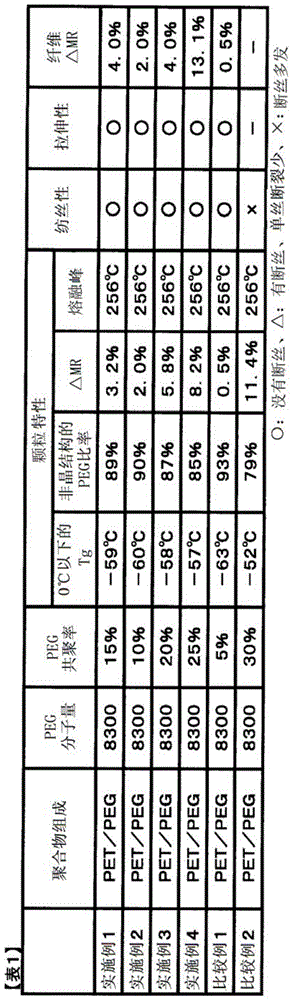

[0088] In the transesterification reaction device of the reaction device that the transesterification reaction device and the polycondensation reaction device are provided with the transfer pipe of 400 mesh filters, add the dimethyl terephthalate of 429g and the ethylene glycol of 274g, 0.1 g of manganese acetate as a transesterification catalyst was transesterified while distilling off methanol at a temperature of 140 to 240° C., and then 0.15 g of trimethyl phosphate was added thereto to synthesize BHT. Then, when the BHT is transferred from the transesterification reaction device to the polycondensation reaction device through the transfer pipe, 75 g of polyethylene glycol with a molecular weight of 8300 (PEG6000 manufactured by Sanyo Chemical Industry Co., Ltd.) heated to a temperature of 70° C. is injected through the In the transfer tube before the filter, start agitation at the same time as the transfer is completed. Next, add 0.1 g of Irganox 1010 (manufactured by BASF...

Embodiment 2~4、 comparative example 1~2

[0093] Except having changed the copolymerization ratio of PEG into the value shown in Table 1, it implemented similarly to Example 1. The results are shown in Table 1.

[0094]

[0095] Like Examples 2-4, when the copolymerization ratio of PEG is in the range of this invention, the polyester fiber with high hygroscopicity can be obtained. However, as in Comparative Examples 1 and 2, when the copolymerization ratio of PEG was out of the range of the present invention, the hygroscopicity was low, or filament breakage often occurred during spinning or drawing, and desired polyester fibers could not be obtained.

Embodiment 5~6、 comparative example 3~4

[0097] Except having changed the molecular weight of PEG into the value shown in Table 2, it carried out similarly to Example 1. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com