Carbon material for negative electrode for lithium ion secondary battery, manufacturing process therefor and use thereof

一种二次电池、制造方法的技术,应用在二次电池、电池电极、负电极等方向,能够解决不期望的反应、初始效率不太高锂离子二次电池等问题,达到初始效率高、优异循环特性、高放电容量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

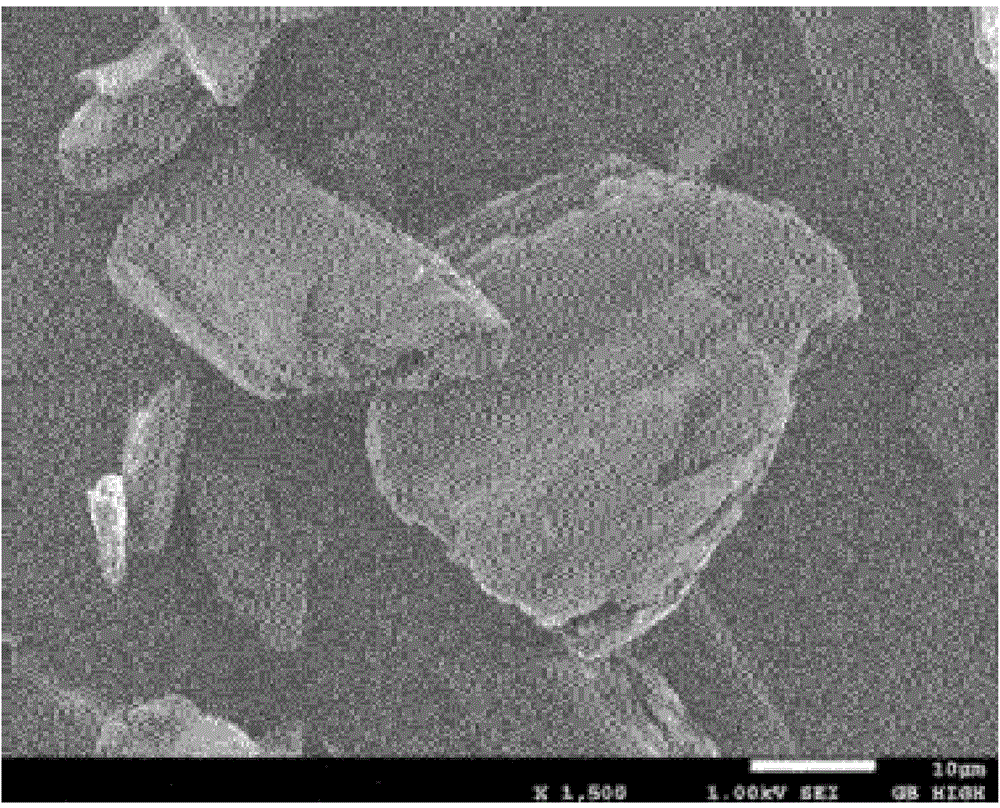

[0144] The crude oil produced in Liaoning Province, China (API 28, wax content 17%, sulfur content 0.66%) was subjected to atmospheric distillation to extract heavy fractions. Using a sufficient amount of Y-type zeolite catalyst, carry out fluidized bed catalytic cracking of heavy fraction at 510°C and normal pressure. Solid components such as catalysts were removed from the cracked product by centrifugation to obtain clear clear oil 1 . The oil is fed to a small delayed coking process. At the drum inlet temperature of 505°C and the drum internal pressure of 600kPa (6kgf / cm 2 ) under the conditions of coking for 10 hours. Then, water cooling was performed to obtain a black mass (green coke).

[0145] The resulting black mass was crushed with a hammer so that the largest size reached about 5 cm. Rotary furnace (electric heater external heating type, alumina 120 mm inner bobbin tube), the black lumps were heated by adjusting the supply amount of the black lumps and the inc...

Embodiment 2

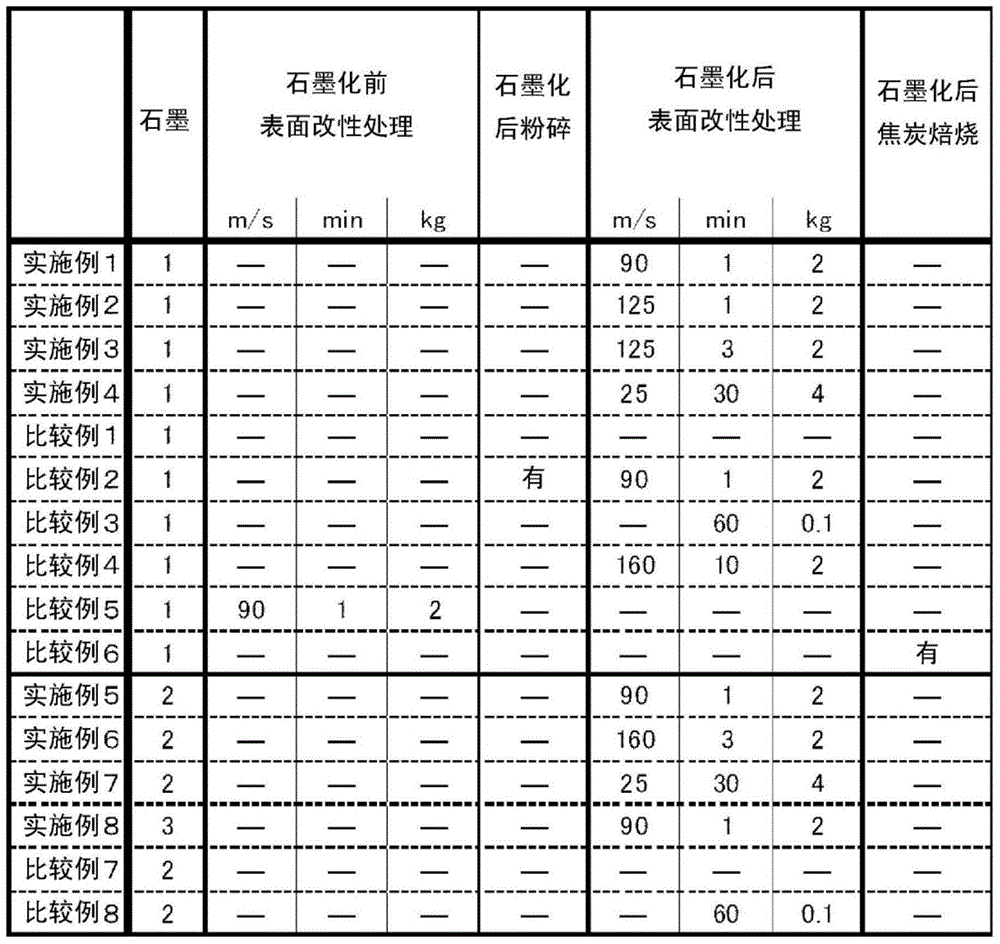

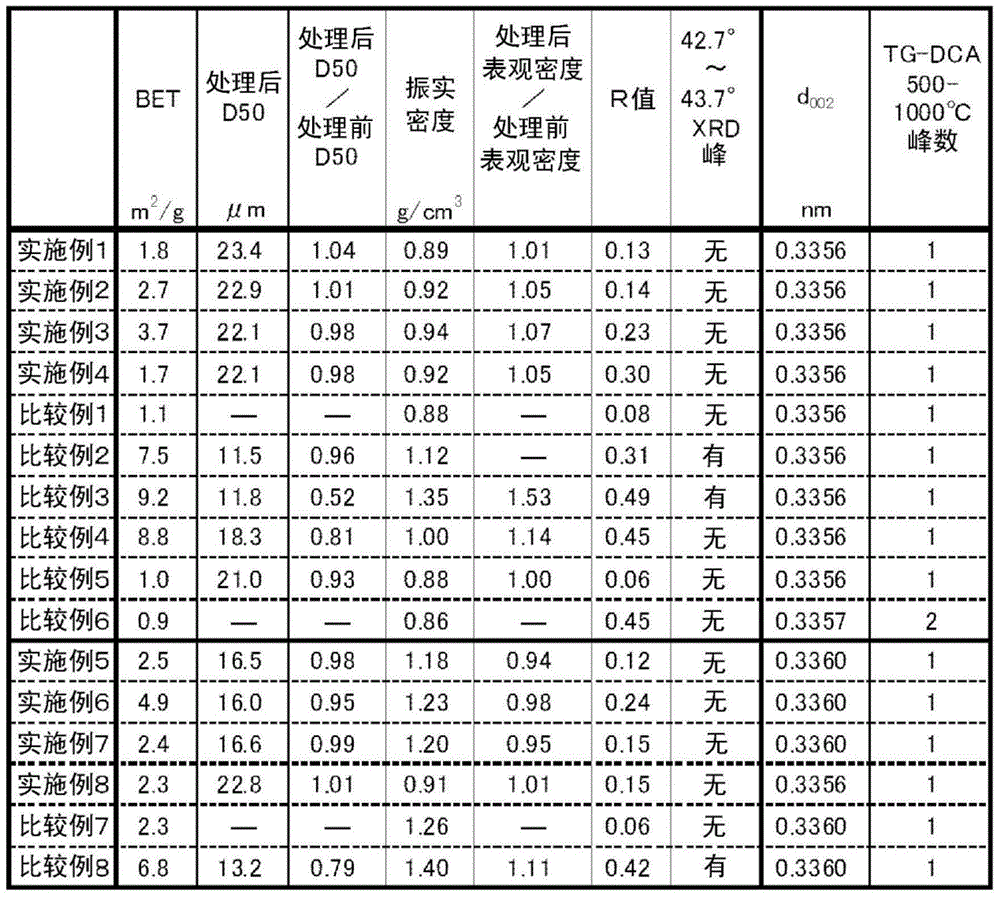

[0151] Surface modification treatment was performed in the same manner as in Example 1 except that the peripheral speed of the pulverizing rotor was changed to 125 m / s. Through surface modification treatment, D50 reaches 22.9μm. Then, the coarse powder was cut off with a sieve having a mesh size of 32 μm to obtain a carbon material having a D50 of 21.0 μm.

[0152] Various physical properties of the obtained carbon material were measured, and electrodes were fabricated, and charge-discharge characteristics and the like were measured. The results are shown in Table 2 and Table 3.

Embodiment 3

[0154] Surface modification treatment was performed in the same manner as in Example 1, except that the peripheral speed of the grinding rotor was changed to 125 m / s and the treatment time was changed to 3 minutes. Through surface modification treatment, D50 reaches 22.1 μm. Then, the coarse powder was cut off with a sieve having a mesh size of 32 μm to obtain a carbon material having a D50 of 20.6 μm.

[0155] Various physical properties of the obtained carbon material were measured, and electrodes were fabricated, and charge-discharge characteristics and the like were measured. The results are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com