Steel ball adding device of ball mill and steel ball adding method

A technology of adding devices and ball mills, applied in grain processing, etc., can solve the problems of high labor intensity, difficulty in supporting the handle, and low work efficiency, and achieve the effects of safe and reliable lifting and transportation, safe and reliable ball output, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

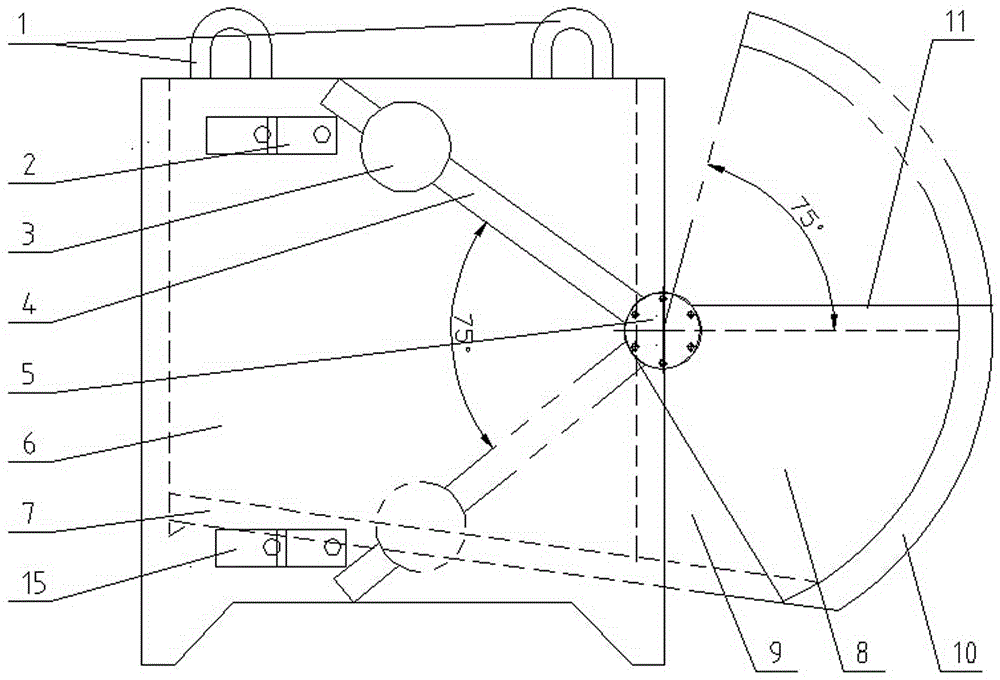

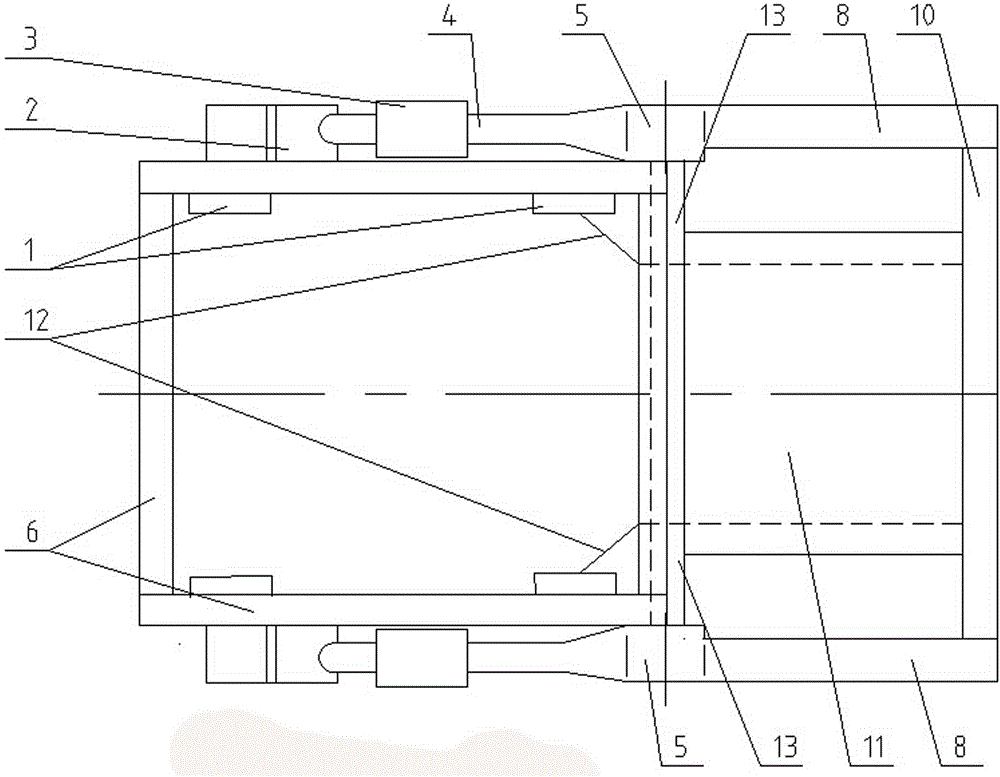

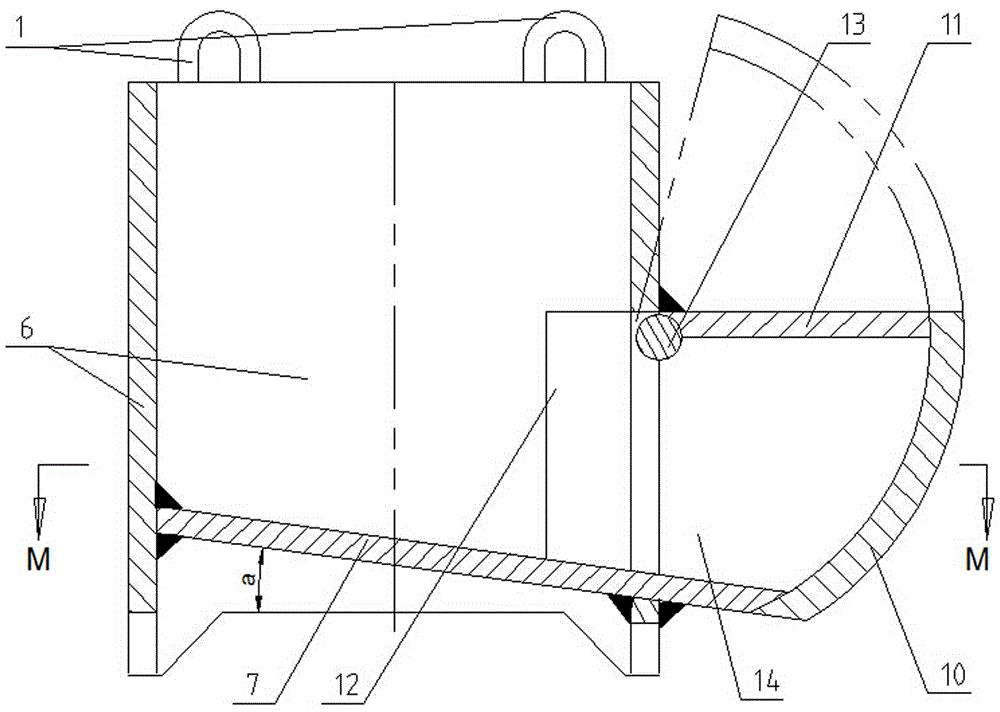

[0020] Example 1 Such as Figure 1-4 Shown: a ball mill steel ball adding device, the bottom of the hollow square iron box is welded with an inclined steel plate 7, the inclined steel plate 7 passes through the lower opening of the vertical steel plate 6 on the side of the ball, the inclined steel plate 7 is connected with two side standing steel plates 9 and The upper horizontal steel plate 11 is welded to form a ball outlet chute 14; the top of the lower opening of the vertical steel plate 6 on the ball outlet side is provided with a horizontal shaft 13, and the small ends of the fan gate side plates 8 on both sides are equipped with rolling bearings installed at both ends of the horizontal shaft 13. The fan-shaped gate 10 that is slidably matched with the outlet of the ball-out chute 14 is welded with the large ends of the fan-shaped gate side plates 8 on both sides. The angle a=18 between the inclined steel plate 7 and the horizontal plane 0 .

[0021] The tail end of...

Embodiment 2

[0023] Example 2 Such as Figure 1-4 Shown: adopt the method for adding steel ball of a kind of ball mill steel ball adding device described in embodiment 1, comprise:

[0024] a. The crane equipped with an electronic crane scale puts the ball mill steel ball adding device that closes the sector gate 10 under the ball outlet gate of the steel ball vertical storage tank, and opens the ball outlet gate of the steel ball vertical storage tank. Roll into and fill the hollow square iron box of the steel ball adding device by its own weight, close the ball outlet gate of the steel ball vertical storage tank; move the upper limit block 2 of the steel ball adding device of the ball mill to the right, and lock the gate handle 4 and the side of the sector gate Plate 8 and sector gate 10 rotate;

[0025] b. The crane lifts the steel ball adding device of the ball mill that closes the sector gate 10 to the feeding port of the ball mill that has stopped. The operator moves the upper lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com