Machining device and method capable of realizing zero taper and reverse taper drilling

A processing device and inverted cone technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as inconvenient integration and complicated processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below with reference to the accompanying drawings.

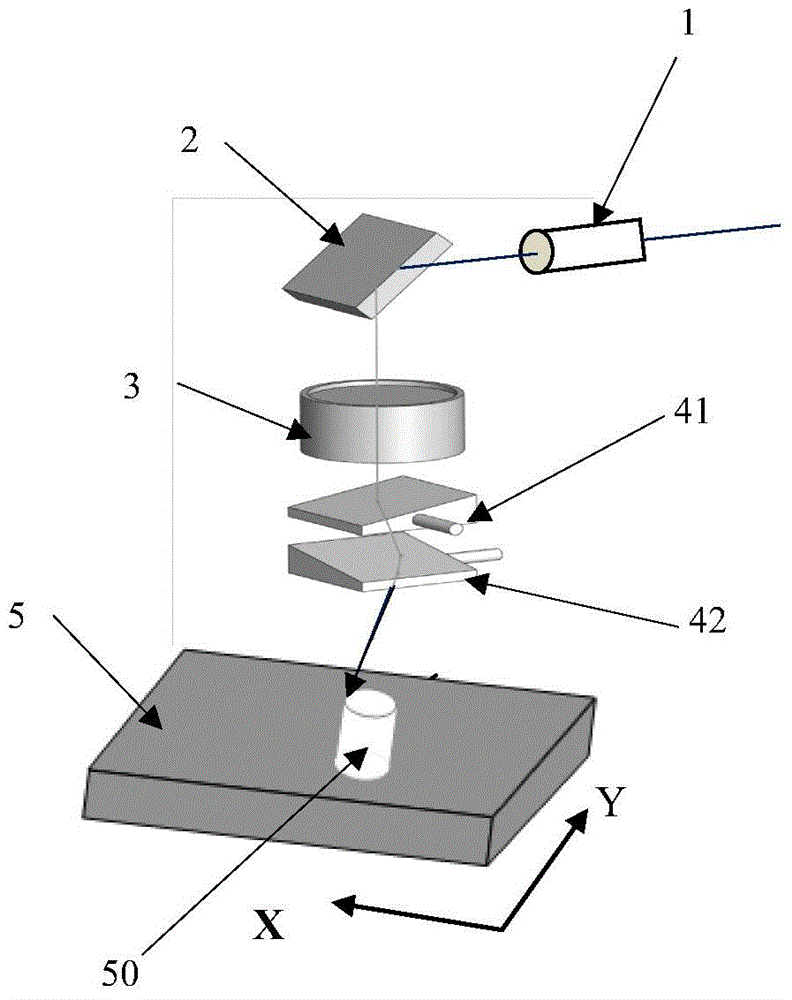

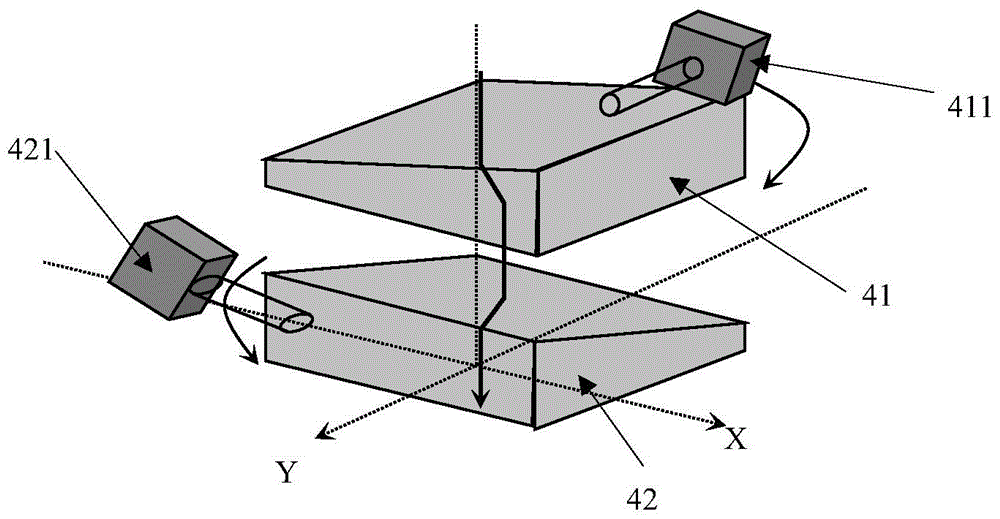

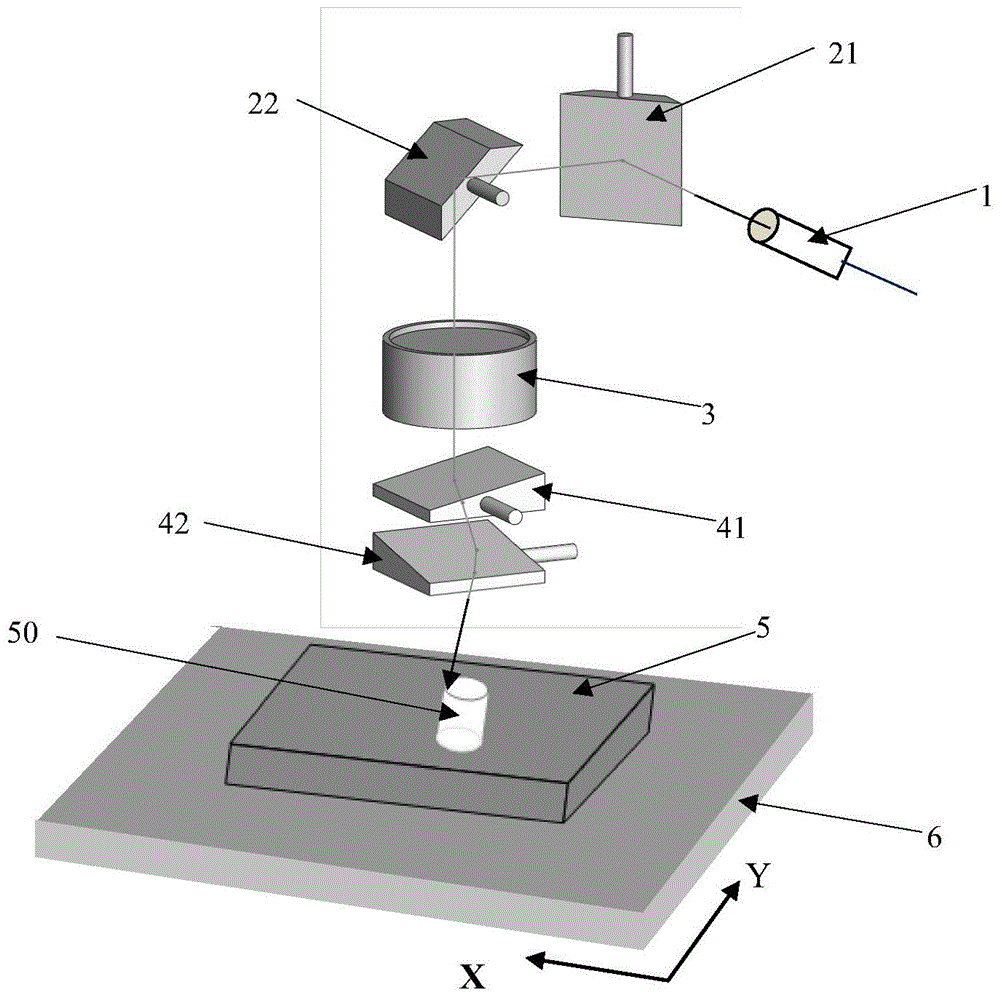

[0034] see figure 1 To attach Figure 5 , a processing device that can realize zero-taper and reverse-taper drilling in the present invention has a laser emitting device, which includes: a dynamic adjustable lens 1; a focusing lens 3; a first wedge-shaped optical glass substrate 41; a second wedge-shaped optical glass substrate 42; wherein, the laser acts on the workpiece to be processed through the dynamically adjustable lens 1, the focusing lens 3, the first wedge-shaped optical glass substrate 41 and the second wedge-shaped optical glass substrate 42, and , the first wedge-shaped optical glass substrate 41 and the second wedge-shaped optical glass substrate 42 are controlled to rotate the device, so as to change the laser irradiation line, thereby realizing the drilling process.

[0035] Please refer to the attached figure 1 , with figure 1 It is a structural sch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com