Multi-stage sealing transformation feeding system

A feeding system and sealing cavity technology, applied in the field of multi-stage sealed variable pressure feeding system, can solve problems such as affecting the safe, stable and reliable operation of high-voltage equipment, harsh working environment of variable pressure silo, and prolonging feeding time. , to achieve the effect of simple structure, easy maintenance and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings.

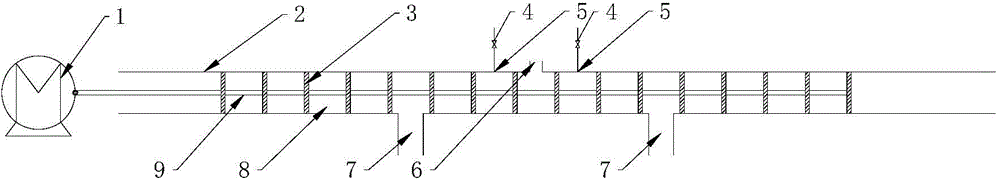

[0021] figure 1 It is a schematic diagram of the conveying device of the multi-stage sealed pressure-changing feeding system. The piston 3 is connected to each other through the connecting rod 9 to form a plurality of independent sealed chambers 8 in the conveying pipeline 2. These sealed chambers 8 form 8 groups of sealed chambers, and the power unit 1 Driven by the driving force, it reciprocates in the conveying pipeline 2. When the sealed chamber 8 on one side is feeding the high-pressure silo, the sealed chamber 8 on the other side is fed through the feeding port 6, which makes every moment, There are corresponding sealing chambers 8 for feeding, pressurizing, discharging and decompressing the high-pressure silo, respectively, so as to ensure the continuity and stability of feeding.

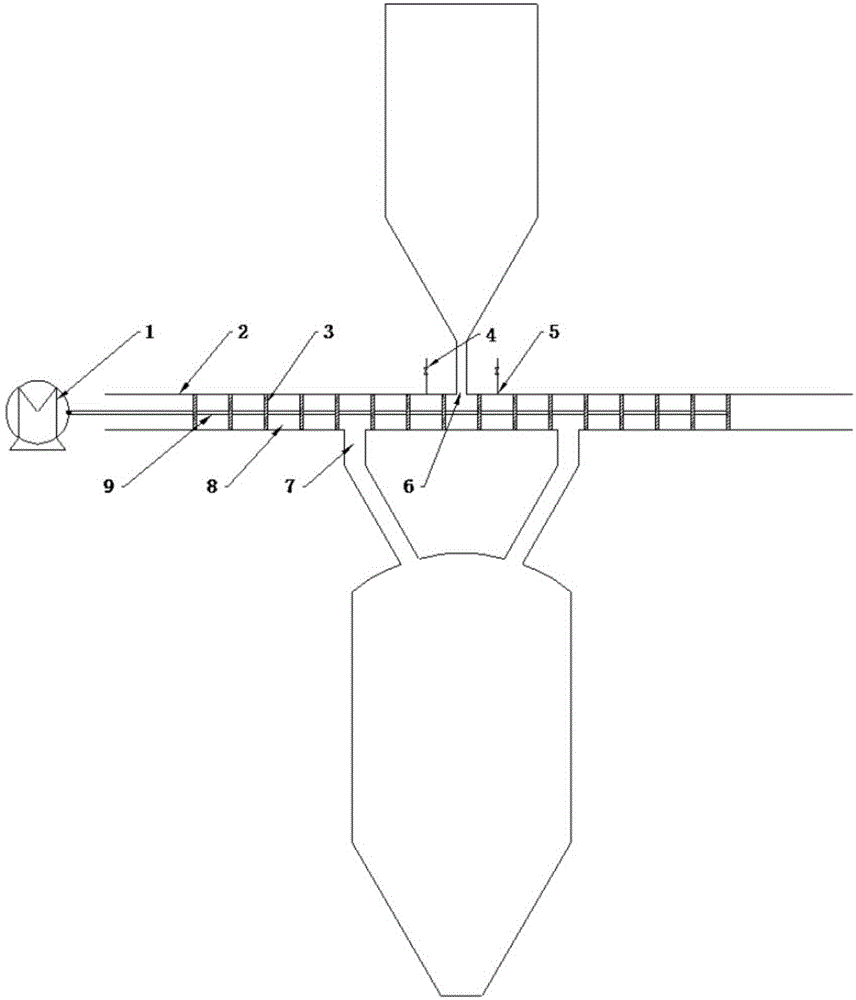

[0022] figure 2 It is a schematic diagram of a multi-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com