Bubble removal technology for glass total-oxygen kiln

A kiln and glass technology, which is applied in the field of glass all-oxygen kiln debubbling technology, can solve the problems of poor color and high-quality glass that are difficult to form, and achieve the effects of reducing heat loss, improving glass quality, and clear steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

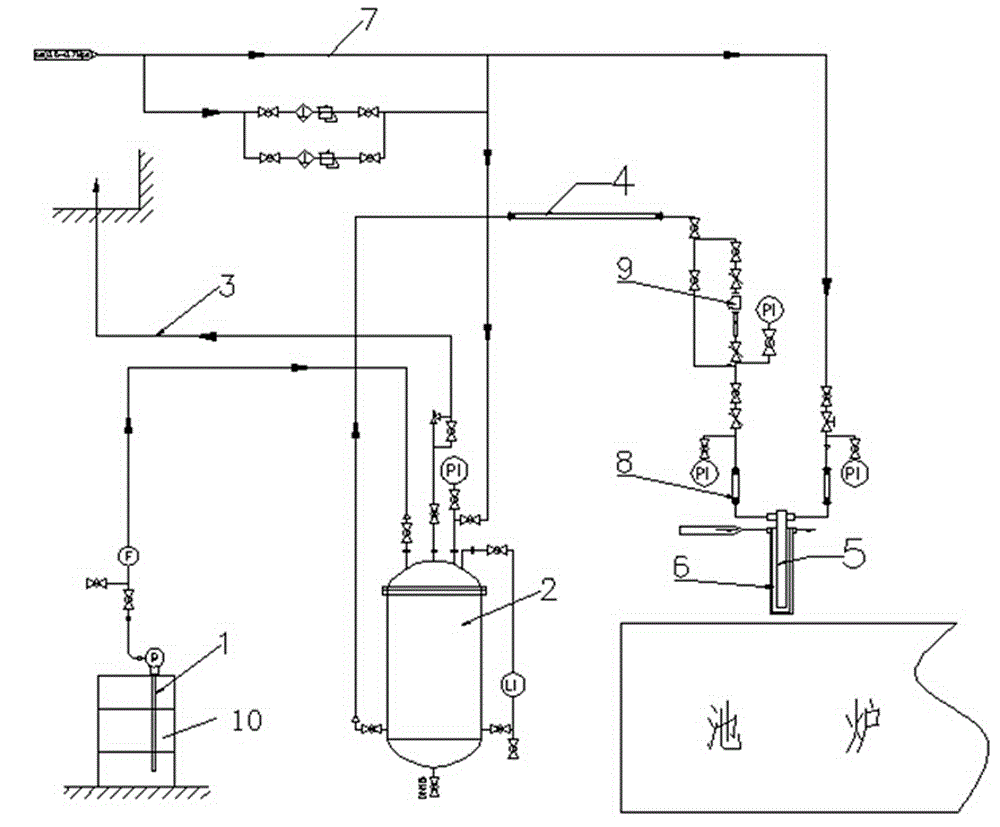

Image

Examples

Embodiment 1

[0033] A glass all-oxygen kiln defoaming process, comprising the following steps:

[0034] Step 1: Prepare a defoaming solution; the defoaming solution is a mixture of tetrabutyltin and kerosene. Among them, the tin content in tetrabutyl tin is ≥33.9%, the tetrabutyl content is ≥99%, the inert component is ≤1.5, and its composition is flammable and poisonous. A mixture of tetrabutyltin and kerosene in a ratio of 1:4.

[0035] Step 2: Mix the defoaming liquid with compressed air; the pressure of the compressed air is 2 bar.

[0036] Step 3: Spray the gas-liquid mixture into the glass all-oxygen kiln. The gas-liquid mixture is in the form of mist. The spray gun is respectively connected with the defoaming liquid and compressed air, and the defoaming liquid and the compressed air are mixed in front of the nozzle of the spray gun. The air is mixed, and the gas-liquid mixture is atomized and sprayed out. Spray into the glass all-oxygen furnace through the spray gun to form a 3-4...

Embodiment 2

[0046] A glass all-oxygen kiln defoaming process, comprising the following steps:

[0047] Step 1: Prepare a defoaming solution; the defoaming solution is a mixture of tetrabutyltin and kerosene. Among them, the tin content in tetrabutyl tin is ≥33.9%, the tetrabutyl content is ≥99%, the inert component is ≤1.5, and its composition is flammable and poisonous. A mixture of tetrabutyltin and kerosene at a ratio of 1:12.

[0048] Step 2: Mix the defoaming liquid with compressed air; the pressure of the compressed air is 4 bar.

[0049] Step 3: Spray the gas-liquid mixture into the glass all-oxygen kiln. The gas-liquid mixture is in the form of mist. The spray gun is respectively connected with the defoaming liquid and compressed air, and the defoaming liquid and the compressed air are mixed in front of the nozzle of the spray gun. The air is mixed, and the gas-liquid mixture is atomized and sprayed out. Spray into the glass all-oxygen furnace through the spray gun to form a 5-...

Embodiment 3

[0051] A glass all-oxygen kiln defoaming process, comprising the following steps:

[0052] Step 1: Prepare a defoaming solution; the defoaming solution is a mixture of tetrabutyltin and kerosene. Among them, the tin content in tetrabutyl tin is ≥33.9%, the tetrabutyl content is ≥99%, the inert component is ≤1.5, and its composition is flammable and poisonous. A mixture of tetrabutyltin and kerosene at a ratio of 1:20.

[0053] Step 2: Mix the defoaming liquid with compressed air; the pressure of the compressed air is 8 bar.

[0054] Step 3: Spray the gas-liquid mixture into the glass all-oxygen kiln. The gas-liquid mixture is in the form of mist. The spray gun is respectively connected with the defoaming liquid and compressed air, and the defoaming liquid and the compressed air are mixed in front of the nozzle of the spray gun. The air is mixed, and the gas-liquid mixture is atomized and sprayed out. Spray into the glass all-oxygen furnace through the spray gun to form a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com