Preparation method of N-lauroyl-glutamate sodium

A technology of sodium lauroyl glutamate and lauroyl glutamic acid, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of low solvent removal efficiency, long removal time, and solvent removal. The problem of high content can achieve the effect of high production efficiency, lower production cost and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

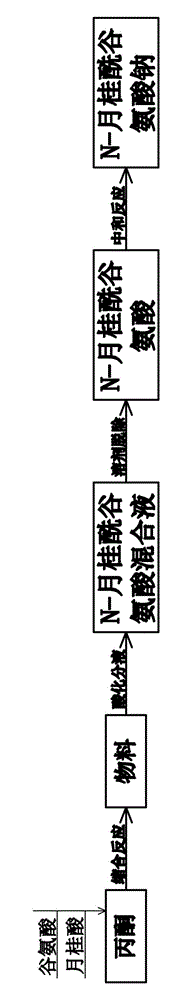

Image

Examples

Embodiment 1

[0027] A preparation method of N-sodium lauroyl glutamate, comprising the following steps:

[0028] Step 1, condensing lauric acid and glutamic acid in a solvent, in this embodiment, the solvent is acetone;

[0029] In step 2, the material obtained after step 1 is completed is subjected to two acidification liquid separation reactions, and the concrete steps of the two acidification liquid separation reactions are,

[0030] a, the temperature is controlled at 55-60°C, the pH is controlled at 2-2.2, and the material obtained after step 1 is completed is subjected to acidification and liquid separation for the first time;

[0031] b. Take the lower oil phase of the material obtained in step a, conduct secondary liquid separation at a temperature of 70-75° C., and a pH of 1.1-1.5, and take the oil phase to obtain a N-lauroyl glutamic acid mixture.

[0032] Step 3, using the rotating scraper thin film evaporation method to perform solvent removal reaction on the N-lauroyl glutami...

Embodiment 2

[0041] There are many similarities between this embodiment and Embodiment 1, and the similarities will not be repeated, and the differences are briefly described as follows:

[0042] The feed flow rate of N-lauroyl glutamic acid mixture in the rotary scraped film evaporator is 340 Kg / h, the temperature of the outer jacket of the rotary scraped film evaporator is 99.7 °C, and the discharge temperature is 42.5 °C. Sampling analysis . The results showed that the acetone content of N-lauroyl glutamic acid mixture was 5.0%, and the acetone content of N-lauroyl glutamic acid was 0.030%.

Embodiment 3

[0044] There are many similarities between this embodiment and Embodiment 1, and the similarities will not be repeated, and the differences are briefly described as follows:

[0045] The feed flow rate of the N-lauroyl glutamic acid mixture in the rotary scraped film evaporator is 440 Kg / h, the outer jacket temperature of the rotary scraped film evaporator is 88.6 °C, and the discharge temperature is 41.3 °C. Sampling analysis . The results showed that the acetone content of N-lauroyl glutamic acid mixture was 5.0%, and the acetone content of N-lauroyl glutamic acid was 0.036%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com