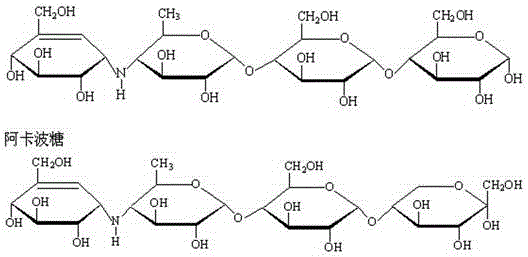

Method for purifying acarbose from solution containing acarbose

An acarbose and solution technology is applied in the field of purifying acarbose from solutions containing acarbose, can solve the problems of increased A component, large batch consumption and high resin breakage rate, and achieves easy operation, The effect of improving the total yield and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare 50 liters of fermented liquid containing 212.0 g of acarbose, in which the content of impurity A is 1.25% (external standard method, relative to acarbose), adjust pH 4.5 with 40% (v / v) acetic acid solution, and plate frame Filtrate to obtain the filtrate containing acarbose, over-equipped with DK110 (H + type) ion-exchange column, the flow rate is controlled at 1.5 times the column volume / hour. 3 -2 type) weakly basic resin column to neutralize to pH 4.0, and neutralize the solution through CT151 strong acid resin (H + Type) column ion exchange column for rough extraction, the flow rate is controlled at 1.1 times the column volume / hour, after the column is loaded, it is eluted with 0.4mol / L hydrochloric acid, the effluent containing acarbose is collected, and the D301 (CO 3 -2 type) weakly basic resin to neutralize to pH 4.5, and then pass the neutralization solution through PT151 (H + type) strong acid resin column ion exchange column for chromatography, th...

Embodiment 2

[0024] Prepare the fermented liquid that contains 304.0 grams of acarbose, wherein A impurity content 0.85% (external standard method, relative to acarbose), adjust pH 4.0 with oxalic acid, obtain the filtrate that contains acarbose by plate and frame filtration, pass Equipped with DK110 (H + type) ion exchange column, the flow rate is controlled at 1.0 times the column volume / hour. 3 -2 type) weakly basic resin column to neutralize to pH 4.6, and neutralize the solution through CT151 strong acid resin (H + Type) column ion exchange column for rough extraction, the flow rate is controlled at 1.3 times the column volume / hour, after the column is loaded, it is eluted with 0.4mol / L hydrochloric acid, the effluent containing acarbose is collected, and the D301 (CO 3 -2 type) Weakly basic resin to neutralize to pH 4.8 and then pass the neutralization solution through PT151 (H + type) strong acid resin column ion exchange column for chromatography, the flow rate is controlled at...

Embodiment 3

[0026] Prepare the fermented liquid that contains 250.4 grams of acarbose, wherein A impurity content 0.98% (external standard method, with respect to acarbose), adjust pH 5.0 with 40% lactic acid (v / v), plate frame filtration obtains containing Acarbose The filtrate of carbose was packed with DK110 (H + type) ion-exchange column, the flow rate is controlled at 0.9 times the column volume / hour. 3 -2 type) weakly basic resin column to neutralize to pH 4.2, and neutralize the solution through CT151 strong acid resin (H + Type) column ion exchange column for rough extraction, the flow rate is controlled at 1.3 times the column volume / hour, after the column is loaded, it is eluted with 0.36mol / L hydrochloric acid, the effluent containing acarbose is collected, and the A845 (CO 3 -2 type) weakly basic resin to neutralize to pH 4.7 and then pass the neutralization solution through PT151 (H + type) strong acid resin column ion exchange column for chromatography, the flow rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com