Preparation method of propofol medium/long-chain fat emulsion injection

A long-chain fat emulsion and propofol technology, applied in the field of medicine, can solve the problems of affecting the emulsification effect, making it difficult to stir evenly, and destroying the stability of co-emulsifiers, so as to avoid local over-alkali, better stability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

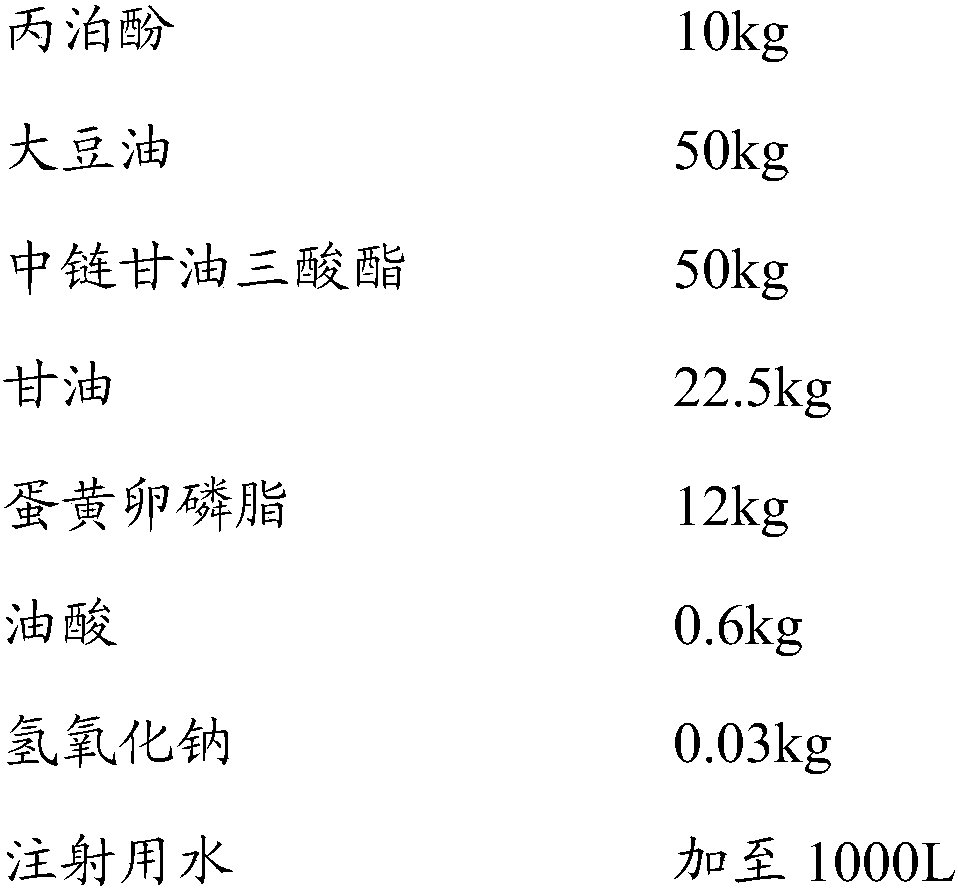

[0033] Propofol medium / long chain fat emulsion injection, batch 1000L, the prescription is as follows:

[0034]

[0035] The preparation method is as follows:

[0036] 1. Under the protection of nitrogen, add glycerin and sodium hydroxide to the water for injection of 90% by volume of the prescription, make up the remaining water for injection, stir and mix evenly, and heat to 65°C±2°C to obtain the water phase;

[0037] 2. Under nitrogen protection, add soybean oil, medium chain triglycerides, egg yolk lecithin, oleic acid, and propofol into the oil phase tank, heat to 65°C±2°C, and cut at 1000rpm Cut and stir to dissolve to obtain the oil phase;

[0038] 3. Under the protection of nitrogen, the oil phase and the water phase are mixed at a weight ratio of 1:6, and sheared at a speed of 2000 rpm by a pipeline type high-shear dispersing emulsifier to obtain colostrum;

[0039] 4. Under the protection of nitrogen, the colostrum is homogenized once by a homogenizer with a ho...

Embodiment 2

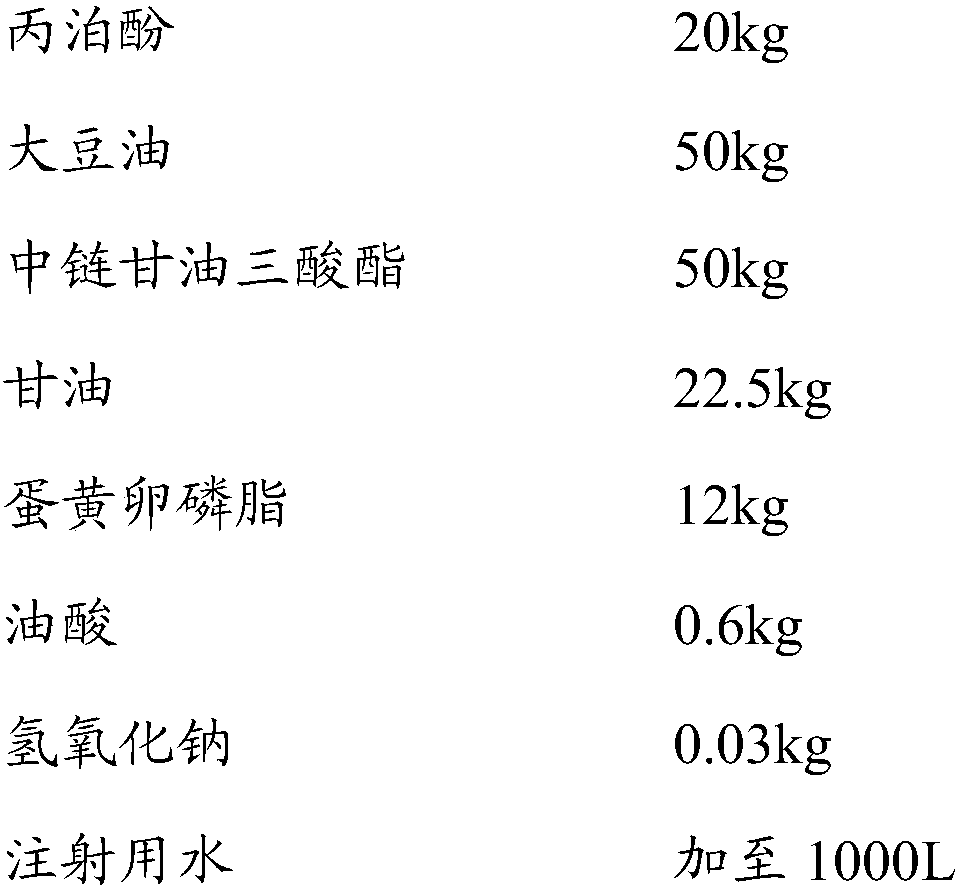

[0042] Propofol medium / long chain fat emulsion injection, batch 1000L, the prescription is as follows:

[0043]

[0044] The preparation method is as follows:

[0045] 1. Under the protection of nitrogen, add glycerin and sodium hydroxide to the water for injection of 90% by volume of the prescription, make up the remaining water for injection, stir and mix evenly, and heat to 65°C±2°C to obtain the water phase;

[0046] 2. Under nitrogen protection, add soybean oil, medium chain triglycerides, egg yolk lecithin, oleic acid, and propofol into the oil phase tank, heat to 65°C±2°C, and cut at 1000rpm Cut and stir to dissolve to obtain the oil phase;

[0047] 3. Under the protection of nitrogen, the oil phase and the water phase are mixed online at a weight ratio of 1:5, and sheared at a speed of 2000 rpm by a pipeline type high-shear dispersing emulsifier to obtain colostrum;

[0048] 4. Under the protection of nitrogen, the colostrum is homogenized once by a homogenizer wi...

Embodiment 3

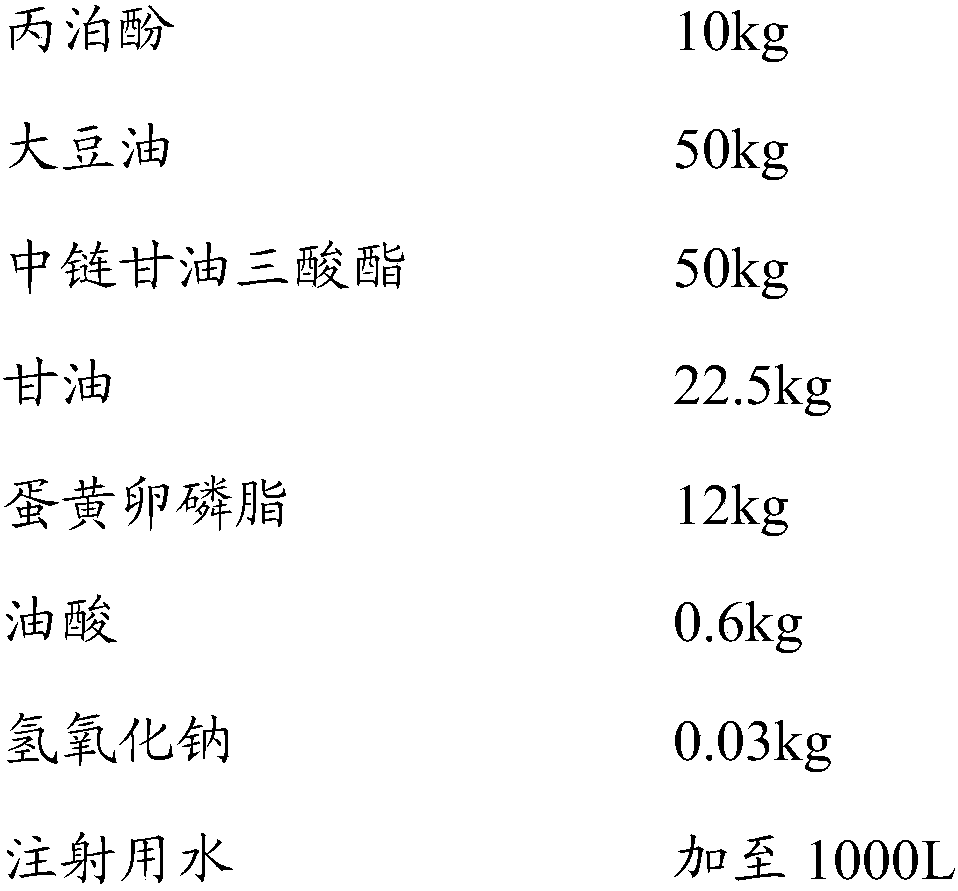

[0051] Propofol medium / long chain fat emulsion injection, batch 1000L, the prescription is as follows:

[0052]

[0053] The preparation method is as follows:

[0054] 1. Under the protection of nitrogen, add glycerin and sodium hydroxide to the water for injection of 90% by volume of the prescription, make up the remaining water for injection, stir and mix evenly, and heat to 65°C±2°C to obtain the water phase;

[0055] 2. Under nitrogen protection, add soybean oil, medium chain triglycerides, egg yolk lecithin, oleic acid, and propofol into the oil phase tank, heat to 65°C±2°C, and cut at 1000rpm Cut and stir to dissolve to obtain the oil phase;

[0056] 3. Under the protection of nitrogen, the oil phase and the water phase are mixed online at a weight ratio of 1:6, and sheared at a speed of 2000 rpm by a pipeline type high-shear dispersing emulsifier to obtain colostrum;

[0057] 4. Under the protection of nitrogen, the colostrum is homogenized once by a homogenizer wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com