Anti-ultraviolet textile

A textile and anti-ultraviolet technology, applied in the field of textiles, can solve the problem that the anti-ultraviolet performance of textiles is not greatly improved, and achieve the effect of excellent washing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

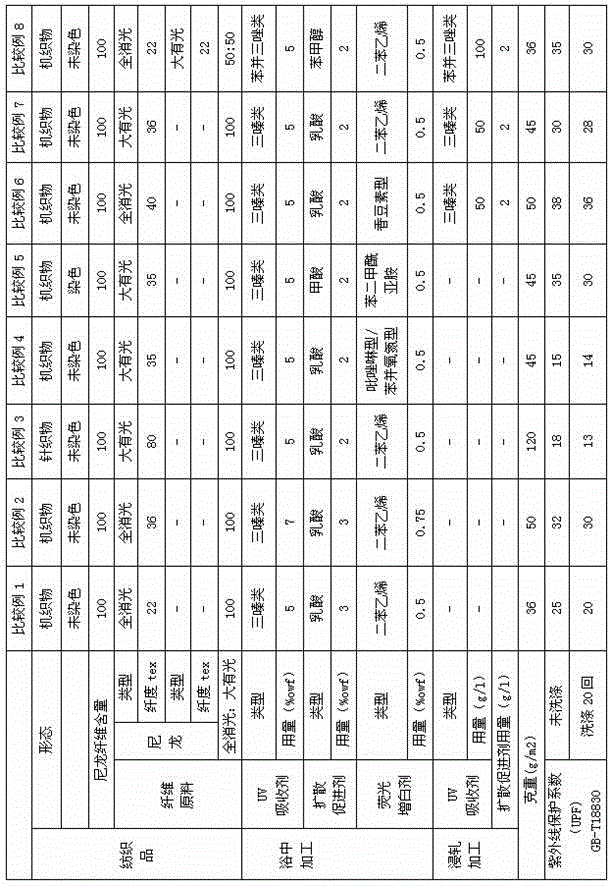

Examples

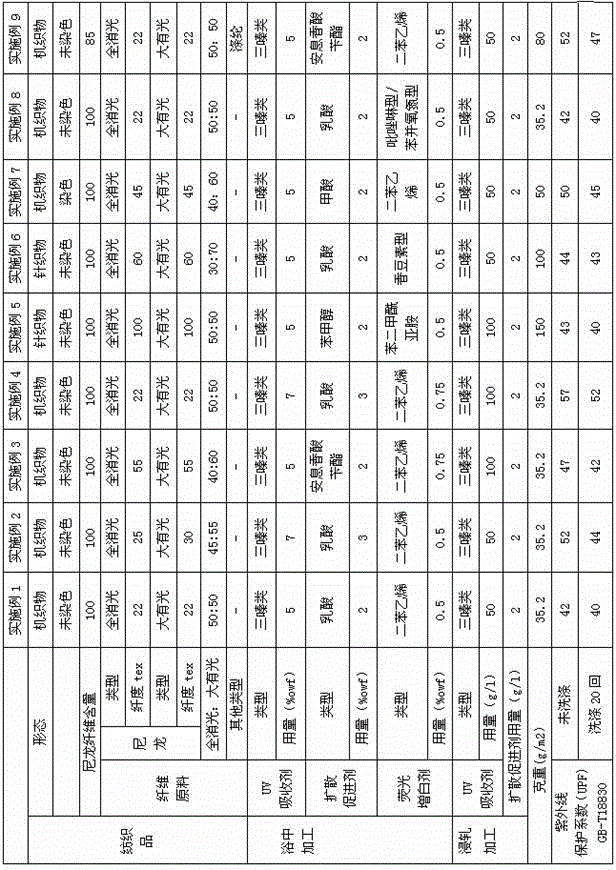

Embodiment 1

[0035] a. Textiles for processing (full extinction / high gloss nylon interwoven fabric, full extinction fiber density 22tex, large light fiber density 22tex);

[0036] b. Preparation of processing fluid in the bath:

[0037] Triazine UV absorber 5%o.w.f.

[0038] Diffusion enhancer lactic acid 2% o.w.f.

[0039] Stilbene type optical brightener 0.5%o.w.f.

[0040] Bath ratio: 1:20

[0041] c. Processing in the bath: mix the above-mentioned prepared processing liquid and nylon textile evenly, put it into the dyeing machine, and keep it warm at 98°C for 30 minutes;

[0042] d. Color fixation and water washing;

[0043] e. Drying and shaping;

[0044] f. Preparation of padding processing fluid:

[0045] Triazine UV absorber 50g / l

[0046] Cation diffusion accelerator 2g / l

[0047] g. Padding and rolling processing: mix the above-mentioned prepared processing liquid evenly, two dipping and two rolling, and the excess rolling rate is 50%;

[0048] h. Drying and setting: dry...

Embodiment 2

[0051] a. Textiles for processing (full extinction / high gloss nylon interwoven fabric, full extinction fiber density 25tex, large light fiber density 30tex);

[0052] b. Preparation of processing fluid in the bath:

[0053] Triazine UV absorber 7%o.w.f.

[0054] Diffusion enhancer lactic acid 3% o.w.f.

[0055] Stilbene type optical brightener 0.5%o.w.f.

[0056] Bath ratio: 1:20

[0057] c. Processing in the bath: mix the above-mentioned prepared processing liquid and nylon textile evenly, put it into the dyeing machine, and keep it warm at 98°C for 30 minutes;

[0058] d. Color fixation and water washing;

[0059] e. Drying and shaping;

[0060] f. Preparation of padding processing fluid:

[0061] Triazine UV absorber 50g / l

[0062] Cation diffusion accelerator 2g / l

[0063] g. Padding processing: mix the above-mentioned prepared processing liquid evenly, two dipping and two rolling, and the rolling rate is 50%;

[0064] h. Drying and setting: drying at 120°C*2min, se...

Embodiment 3

[0067] a. Textiles for processing (full extinction / high gloss nylon interwoven fabric, full extinction fiber density 55tex, large light fiber density 55tex);

[0068] b. Preparation of processing fluid in the bath:

[0069] Triazine UV absorber 5%o.w.f.

[0070] Diffusion enhancer benzyl benzoate 2% o.w.f.

[0071] Stilbene type optical brightener 0.75%o.w.f.

[0072] Bath ratio: 1:20

[0073] c. Processing in the bath: mix the above-mentioned prepared processing liquid and nylon textile evenly, put it into the dyeing machine, and keep it warm at 98°C for 30 minutes;

[0074] d. Color fixation and water washing;

[0075] e. Drying and shaping;

[0076] f. Preparation of padding processing fluid:

[0077] Triazine UV absorber 100g / l

[0078] Cation diffusion accelerator 2g / l

[0079] g. Padding and rolling processing: mix the above-mentioned prepared processing liquid evenly, two dipping and two rolling, and the excess rolling rate is 50%;

[0080] h. Drying and settin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com