Antistatic fabric

An antistatic and fabric technology, applied in the field of textiles, can solve the problems of affecting the quality of finished products, large dosage, poor compatibility, etc., and achieve the effects of simple and easy processing method, superior washing durability, and good water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

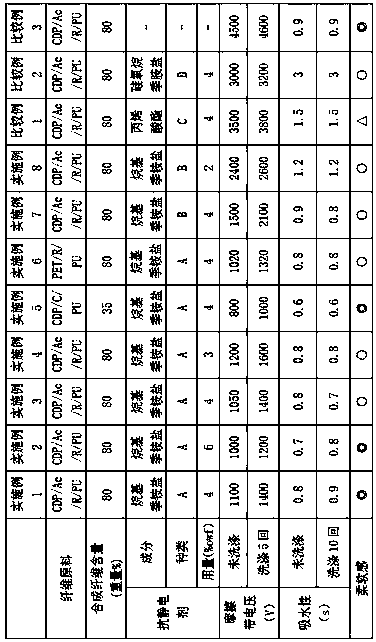

Examples

Embodiment 1

[0048] On the circular knitting machine, use 84dtex-72f-CDP DTY, 40 counts of viscose / acrylic blended yarn and 22dtex spandex bare yarn to weave the weft plain stitch in the ratio of 45:50:5 to obtain gray cloth, and then the gray cloth is woven at 90 ℃*10min for pretreatment, then use cationic dyes to dye CDP and acrylic fibers at 115℃*30min, and then use reactive dyes to dye viscose fibers at 60℃*60min to obtain 150g / ㎡ knitted fabric.

[0049] Antistatic treatment was carried out on the dyed knitted fabric above under the conditions of 70°C*20min and liquor ratio 1:20, and the antistatic fabric was obtained after drying.

[0050] Antistatic agent A 4%.owf

[0051] Then put the fabric after antistatic processing into the processing solution of the following composition, and use a dipping and rolling method with a rolling rate of 70%-80% for treatment, and dry it at 130°C*2min to obtain the present invention For fabrics, see Table 1 for specific parameters.

[0052] Polyest...

Embodiment 2

[0058] Adjust the amount of antistatic agent A to 6%.owf, and the rest are the same as in Example 1 to obtain the fabric of the present invention. The specific parameters are shown in Table 1.

Embodiment 3

[0060] Padding processing is not carried out, and the rest is the same as in Example 1 to obtain the fabric of the present invention, and the specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com