Movable pump station of emulsified liquid for mine, with function of preventing water overflow

An anti-overflow and emulsion technology, which is applied to engine components, fluid pressure actuating devices, valve operation/release devices, etc., can solve problems such as wasting water sources, affecting the underground environment, and overflowing decompression water tanks, so as to save water resources , The effect of protecting the underground environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

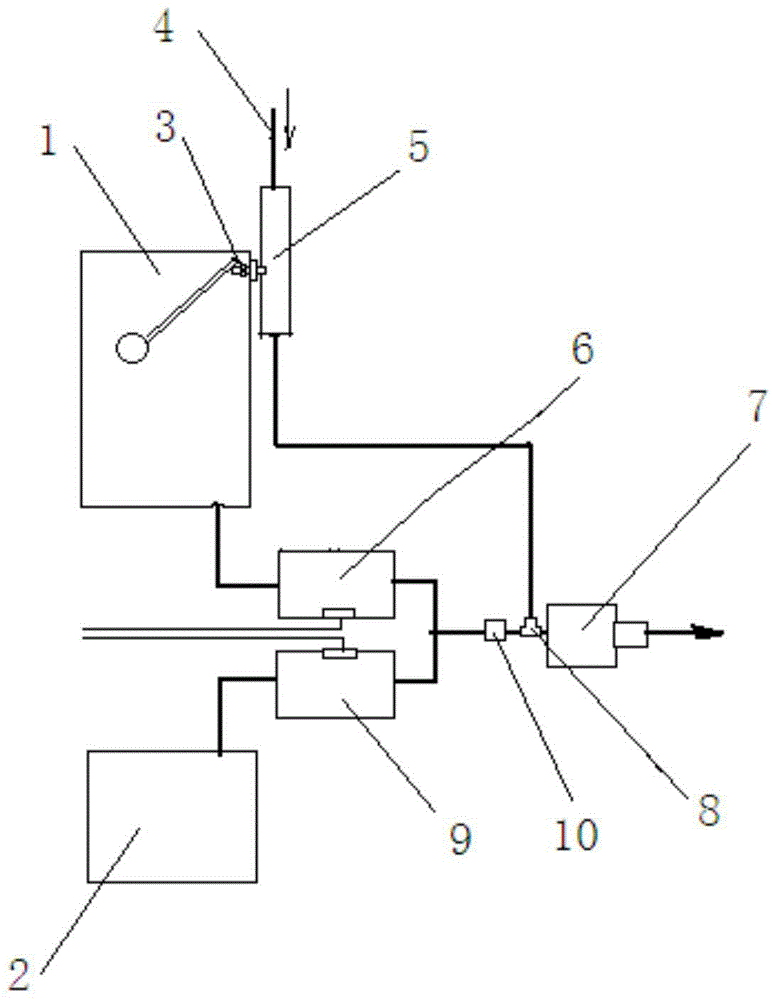

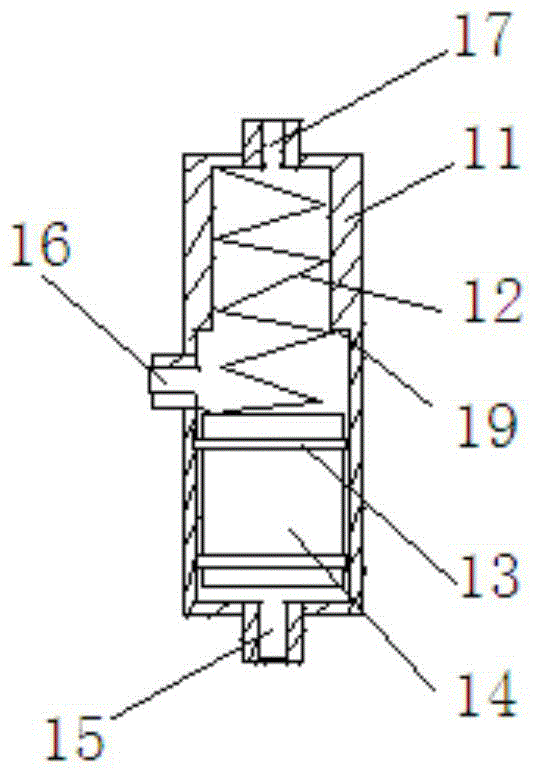

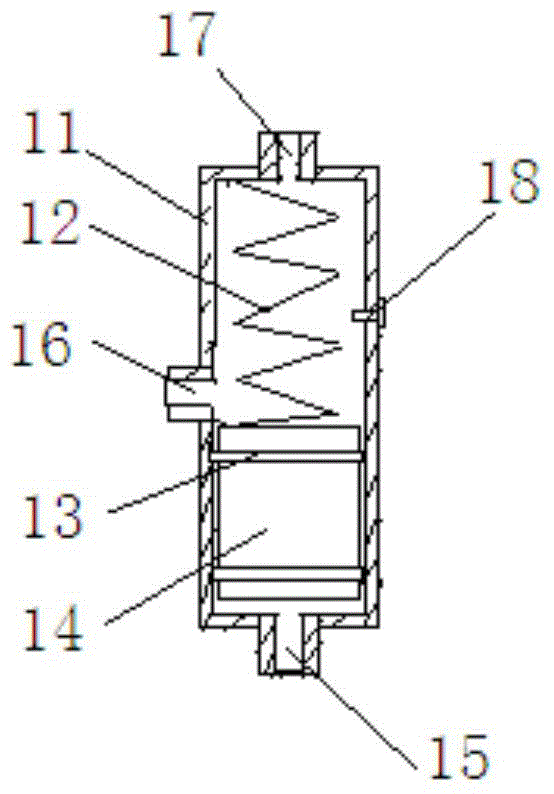

[0011] Such as figure 1 Shown is a mine emulsion mobile pump station with anti-overflow function, which is provided with an emulsified oil tank 2, a decompression water tank 1, a water pump 6, an oil pump 9, a one-way valve 10 and a combined valve body 7 on the chassis; Wherein the decompression water tank 1 is also provided with a float valve 3 for automatic water intake, and the water pump 6 and the oil pump 9 are electric pumps; it also includes a water blocking valve 5 connected to the water inlet of the float valve 3. Connect a tee 8 again on the high-pressure pipeline; the structure of the water blocking valve 5 is as follows: figure 2 As shown, it includes a valve body 11, the valve body 11 is provided with upper and lower chambers, the upper chamber is provided with a pressure spring 12 higher than the tap water inlet pressure and lower than the rated working pressure of the pump station, and the lower chamber is provided with a device There is a piston rod 14 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com