Bidirectional hinge support device

A two-way hinge and fixed support technology, applied in the direction of measuring devices, transmission parts, instruments, etc., can solve the problems of high noise in the test environment, low test efficiency, heat at the connection between the wire rope and the pulley, etc., and achieve small load fluctuations, Improved test efficiency and good test environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below.

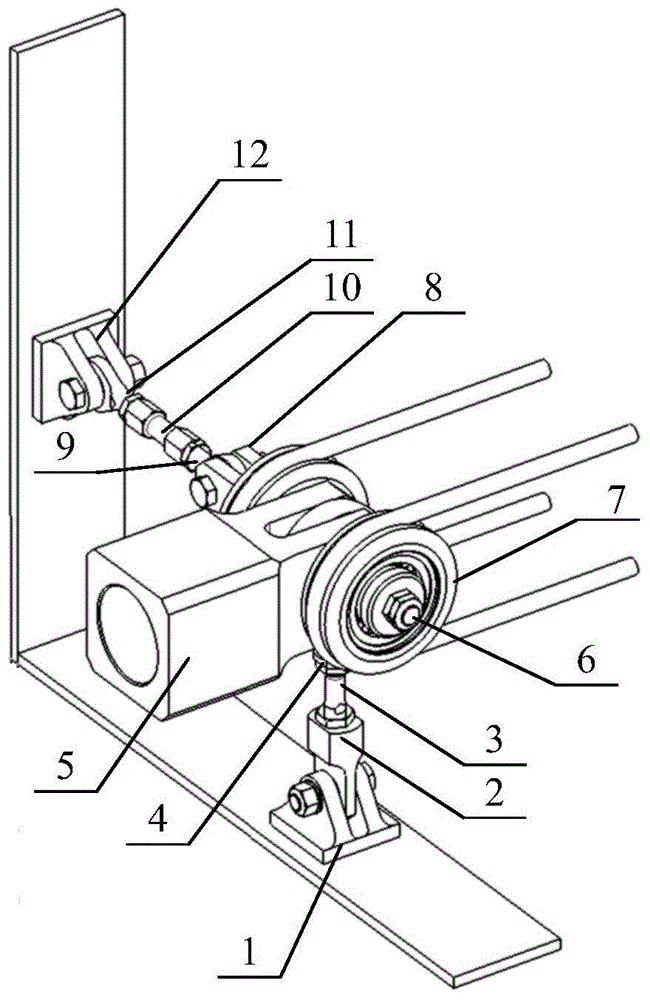

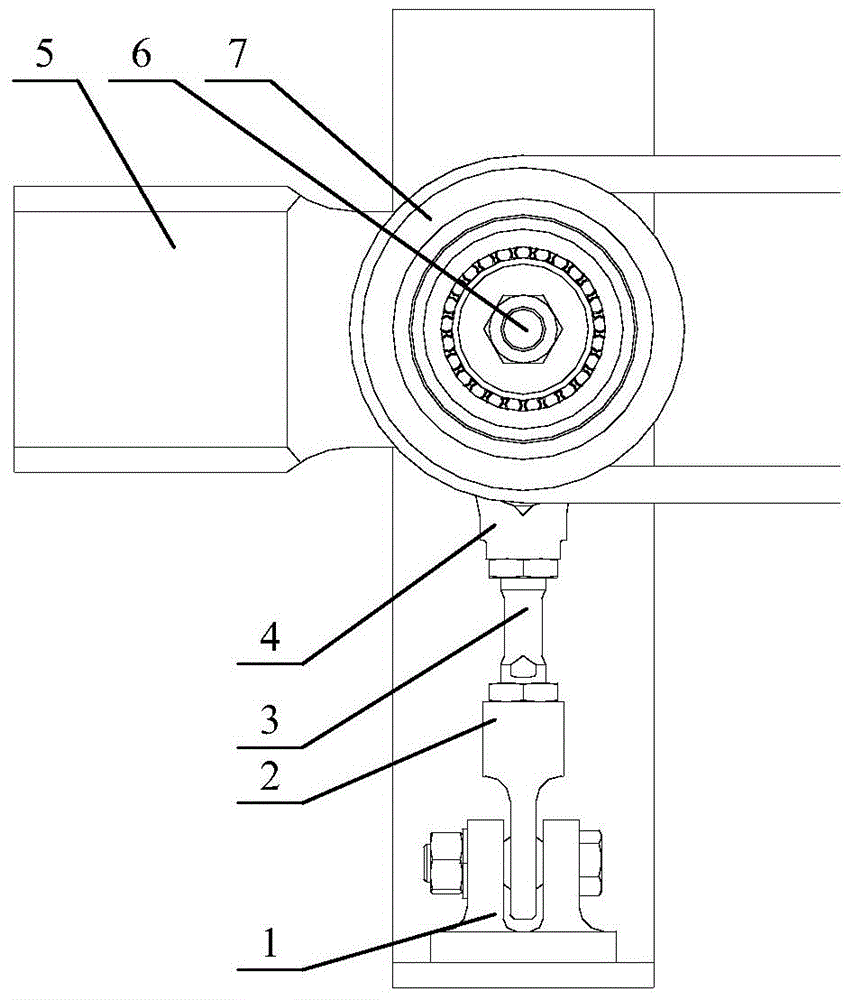

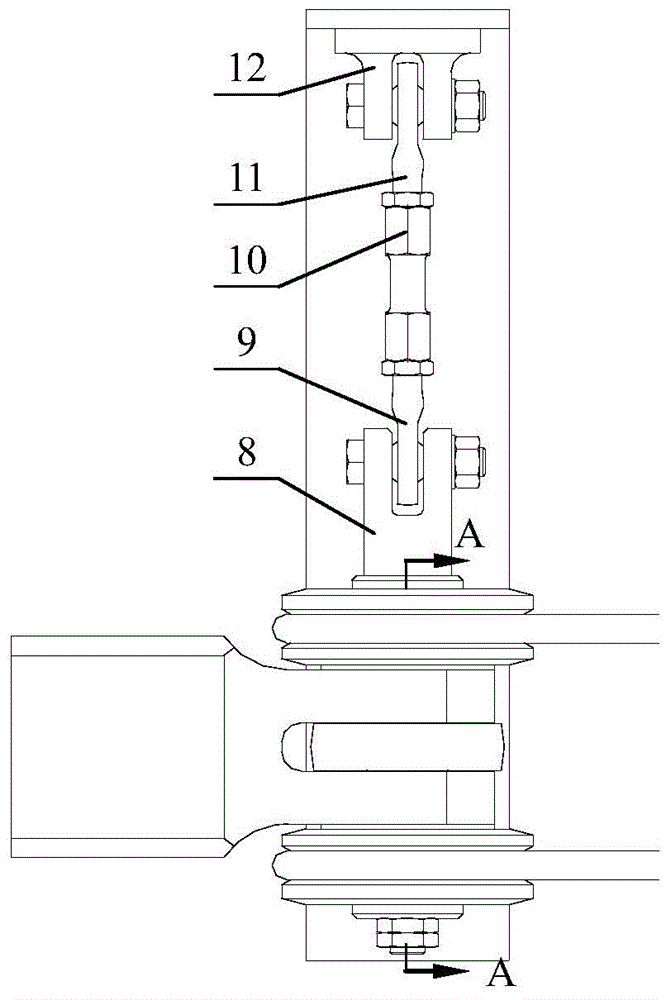

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a two-way hinge bearing device, comprising:

[0027] Including the No. 1 fixed support 1, the No. 1 shank joint bearing assembly 2, the swing force measuring rod 3, the shank spherical roller bearing assembly 4, the simulated blade connection joint 5, the connection pin 6, the wire rope pulley assembly 7, the connection support Seat 8, No. 2 shank joint bearing assembly 9, shimmy force measuring rod 10, No. 3 shank joint bearing assembly 11, No. 2 fixed support 12; swinging force measuring rod 3 is a rod-shaped structure with external threads at both ends , the shimmy force measuring rod 10 is a rod-shaped structure with internal threads at both ends, one end of the No. 1 fixed support 1 is fixedly connected with the No. One end of the force bar 3 is connected; the other end of the swinging force bar 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com