Fault determining and after-treatment process of infrared sizing of continuous casting machine

A fault judgment, continuous casting machine technology, applied in computer control, instruments, simulators, etc., can solve the problems of long billet cutting, threat to personnel safety, waste of manpower and material resources, etc., to achieve timely supplementary cutting, ensure personnel safety, and easy manipulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

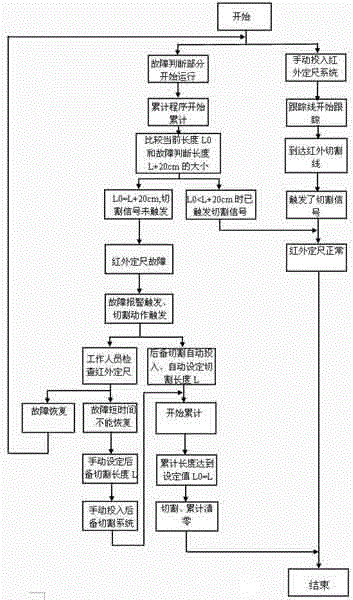

[0020] Example 1: Such as figure 1 The fault judgment and post-processing process of a continuous casting machine infrared cut-to-length cutting device shown, the detailed operation process is as follows:

[0021] 1) Manually set the cutting length L of the billet in the infrared cut-to-length cutting system at the operation site, and the cut-to-length system will issue a blank clamping command after tracking the length and start cutting;

[0022] 2) During the tracking process, the cutting length L of the steel billet is recorded by the PLC, and at the same time, L+20cm is used as the length basis for judging the infrared sizing fault, and the infrared sizing cutting system performs continuous cutting operations;

[0023] 3) The length of the billet reaches L+20cm in the process of advancing, and the infrared sizing cutting system still does not issue a cutting command, which is judged to be a fault of the infrared sizing;

[0024] 4) The infrared fixed-length cutting syst...

Embodiment 2

[0027] Example 2: Such as figure 1 The switching buttons of the common infrared fixed-length cutting system and the following cutting system shown in the present invention are respectively an automatic switching button and a manual switching button, and the described automatic switching button is arranged in the PLC control system, and the described manual switching button is set In terms of cutting and sizing, the operation is flexible and easy to switch. The common and backup systems are one for use and the other for standby, and the cutting system can be automatically switched in case of failure, which basically guarantees zero missed cuts in the sizing cutting of the continuous casting machine.

Embodiment 3

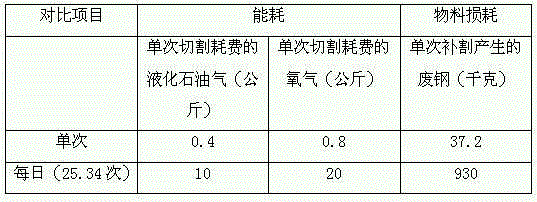

[0028] Example 3: Working example of the present invention: the production data obtained after the enterprise adopts this operating process is compared with the production data before adopting this operating process, and the energy loss and material loss of the enterprise in the production process are obtained as shown in the following table: The following table is There are 2 continuous casting machines and 8 casting strands in the factory area. The billet needs to be manually cut and recorded within 3 months due to the continuous casting machine's sizing failure. The record is the energy loss when receiving the cutting.

[0029]

[0030] From the actual records in the above table, we can know that during the manual cutting operation, the average number of manual cuttings per day (three teams 24 hours) due to cutting long branches and missed cuttings is 25.34 times in three months About; take the value 25 times. At the same time, because 0.4 kg of liquefied petroleum gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com