na 125 i solution production device

A production device and solution technology, which is applied in the field of Na125I solution production devices, can solve the problems of many transfer links of radioactive materials, radioactive pollution target making devices, and large leakage of target materials, so as to reduce transfer links, avoid radiation dose, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

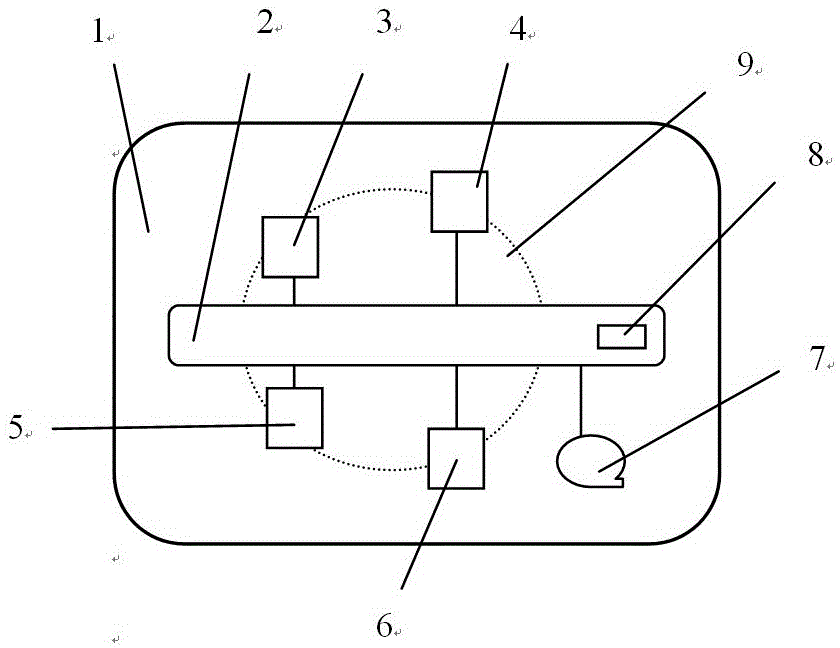

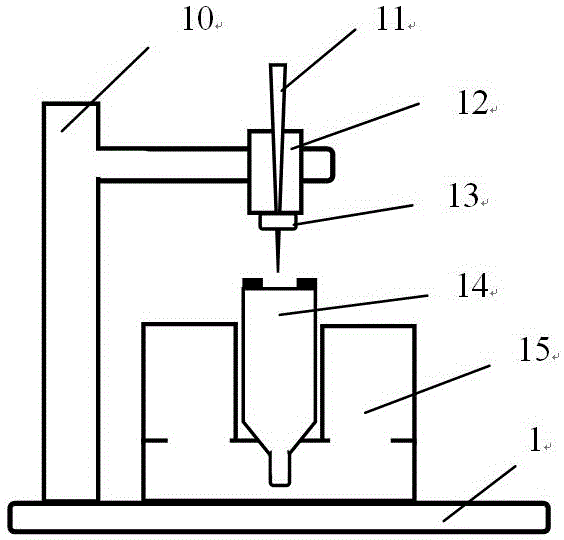

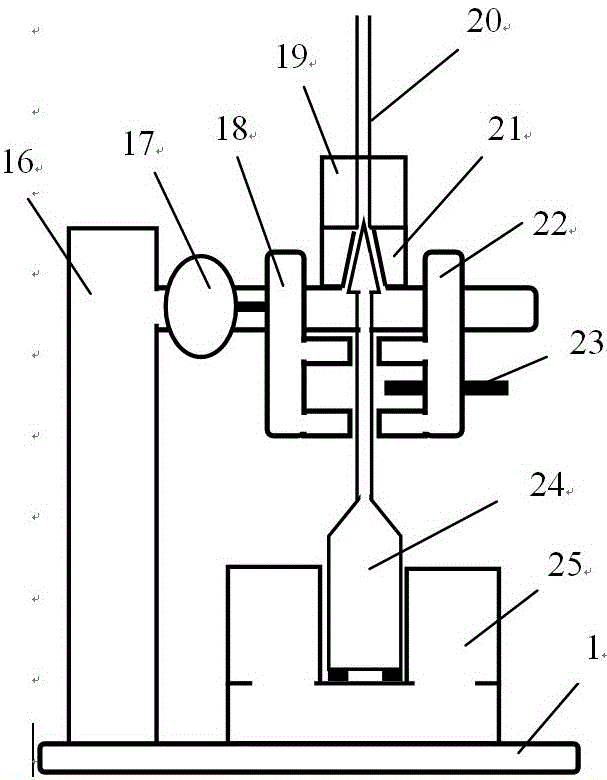

[0023] figure 1 is the Na of the present invention 125 The overall structural block diagram of the I solution production device, figure 2 It is a structural schematic diagram of the target opener in the present invention, image 3 It is a structural schematic diagram of the solder filling device in the present invention, Figure 4 It is a schematic structural view of an air-inverting tank in the present invention, Figure 5 It is a structural schematic diagram of the reactor in the present invention. exist Figure 1~Figure 5 In the present invention, Na 125 1 solution production device, comprises bench 1, pours gas tank 2, target opener 3, fills welding device 4, reactor 5, raw material tank 6, vacuum pump 7, pressure gauge 8, liquid nitrogen pump 9, and its connection relation is, The described gas tank 2, target opener 3, welding device 4, reactor 5, raw material tank 6, and vacuum pump 7 are all arranged on the platform 1 and fixedly connected with the platform 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com