Environment-protecting air purification material and preparation method thereof

An air purification material and an environmentally friendly technology, applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of unsightly appearance and easy flying of activated carbon, etc., and achieve an increase in filtration area, simple preparation method, and easy preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 65kg of polymaleimide, 43kg of polyoctyl suberate, 15kg of activated carbon fiber, 13kg of diatomaceous earth, 1.5kg of humic acid, 1.3kg of glycerol stearate, and 2kg of sodium cocoyl glycinate ;

[0023] (2) Mix the above components evenly by wet ball milling method, keep warm at 100°C for 2 hours, add 2kg of silk protein, and stir evenly;

[0024] (3) Heating at 205° C., pressing to form, and drying to obtain an environment-friendly air purification material.

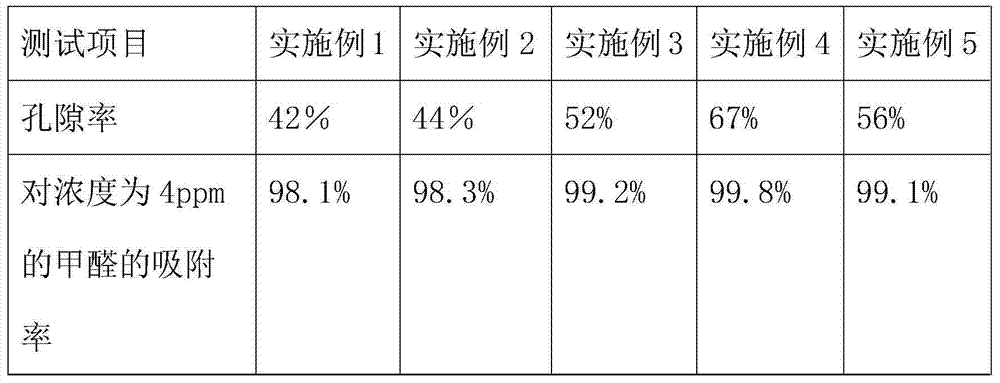

[0025] The performance test results of the prepared environment-friendly air purification materials are shown in Table 1.

Embodiment 2

[0027] (1) Weigh 65kg of polymaleimide, 35kg of polyoctyl suberate, 12kg of activated carbon fiber, 11kg of diatomaceous earth, 1.5kg of humic acid, 1.3kg of glycerol stearate, and 2kg of sodium cocoyl glycinate ;

[0028] (2) Mix the above components evenly by wet ball milling method, keep warm at 100°C for 2 hours, add 2kg of silk protein, and stir evenly;

[0029] (3) Heating at 205° C., pressing to form, and drying to obtain an environment-friendly air purification material.

[0030] The performance test results of the prepared environment-friendly air purification materials are shown in Table 1.

Embodiment 3

[0032] (1) Weigh 84kg of polymaleimide, 43kg of polyoctyl suberate, 15kg of activated carbon fiber, 23kg of diatomaceous earth, 2.6kg of humic acid, 2.8kg of glycerol stearate, and 3kg of sodium cocoyl glycinate ;

[0033] (2) Mix the above components uniformly by wet ball milling method, keep warm at 110° C. for 3 hours, add 5 kg of silk protein, 1.2 kg of polydimethylsiloxane diquaternary ammonium salt and 0.9 kg of polyseburea, and stir evenly;

[0034] (3) Heating at 210° C., pressing to form, and drying to obtain an environment-friendly air purification material.

[0035] The performance test results of the prepared environment-friendly air purification materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com