Pico-second laser combined machining SLM device and laser rapid prototyping methods

A technology of laser rapid prototyping and composite processing, which is applied in the direction of additive processing, process efficiency improvement, and energy efficiency improvement. Reduce Workflow Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

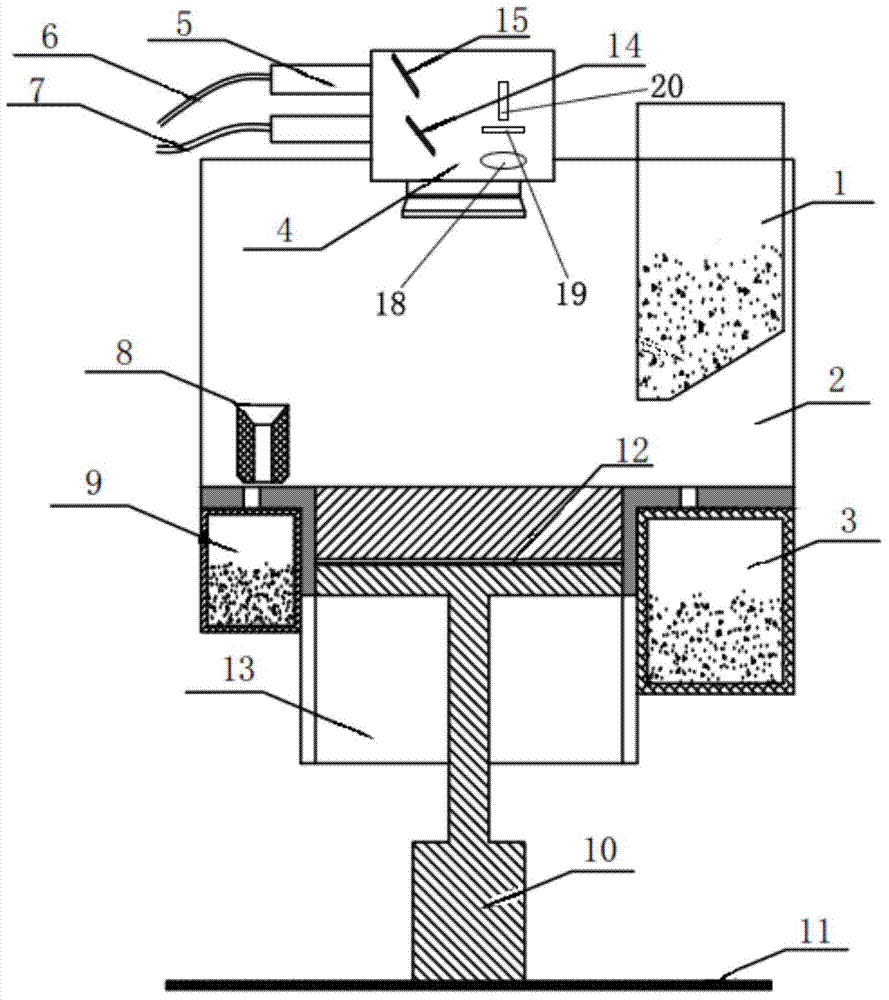

Embodiment 1

[0033] A picosecond laser compound processing SLM equipment, such as figure 1 As shown, including a work platform 11, the work platform 11 is provided with a motor unit 10, the motor unit 10 is provided with a restraint cylinder 13, the restraint cylinder 13 is used to assemble the formed parts, and the restraint cylinder 13 is connected with a bearing platform 12 for placing parts. The powder spreading system is provided on the carrying platform 12, the powder spreading system includes the powder collecting barrel a3 and the powder collecting barrel b9 arranged on both sides of the restraining cylinder 13, the powder spreading system also includes a scraper 8 arranged on the carrying platform 12 and a The powder-carrying barrel 1 above the carrying platform 12 is provided with a sealed cabin 2 on the bearing platform 12, the powder spreading system is inside the sealed cabin 2, and the upper part of the sealed cabin 2 is provided with a vibrating mirror unit 4. The vibrating m...

Embodiment 2

[0035] On the basis of Embodiment 1, the first lens may also be a beam splitter.

Embodiment 3

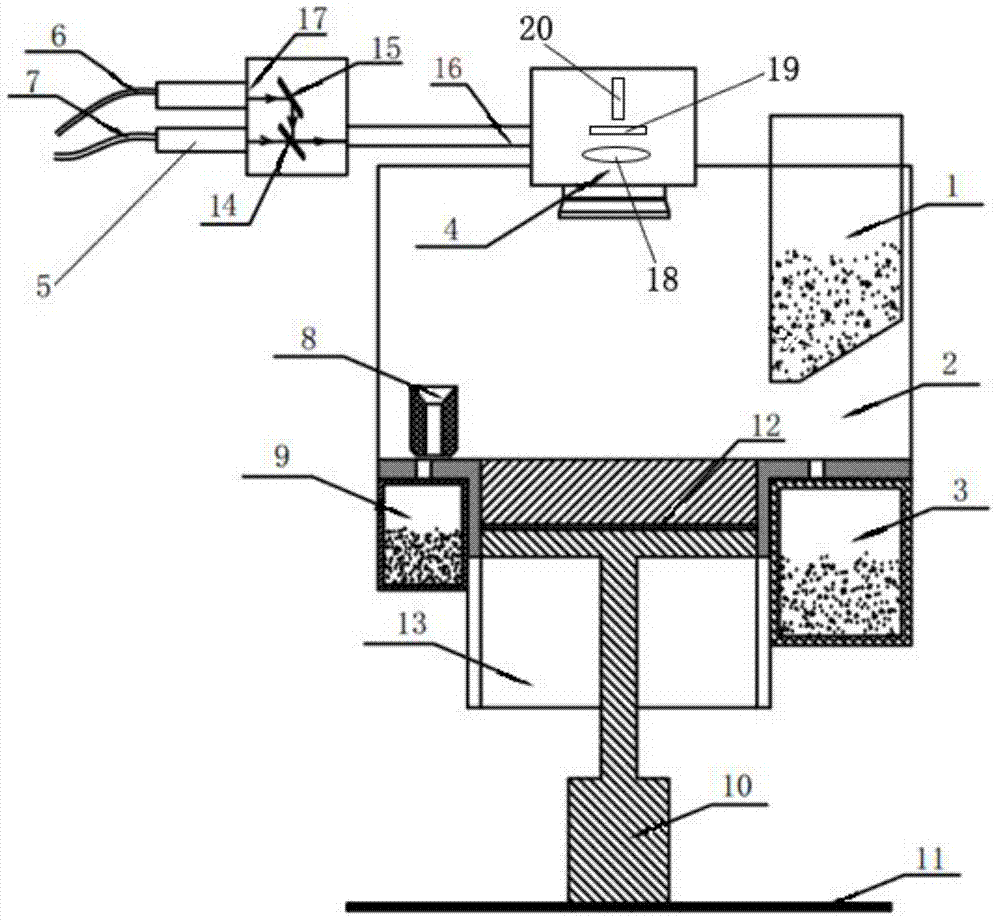

[0037] A picosecond laser compound processing SLM equipment, such as figure 2 As shown, including a work platform 11, the work platform 11 is provided with a motor unit 10, the motor unit 10 is provided with a restraint cylinder 13, the restraint cylinder 13 is used to assemble the formed parts, and the restraint cylinder 13 is connected with a bearing platform 12 for placing parts. The powder spreading system is provided on the carrying platform 12, the powder spreading system includes the powder collecting barrel a3 and the powder collecting barrel b9 arranged on both sides of the restraining cylinder 13, the powder spreading system also includes a scraper 8 arranged on the carrying platform 12 and a The powder-carrying barrel 1 above the carrying platform 12 is provided with a sealed cabin 2 on the bearing platform 12, the powder spreading system is inside the sealed cabin 2, and the upper part of the sealed cabin 2 is provided with a vibrating mirror unit 4. The vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com