Method for treating acidic polymetallic sulfate industrial wastewater by use of sulfate-reducing bacteria

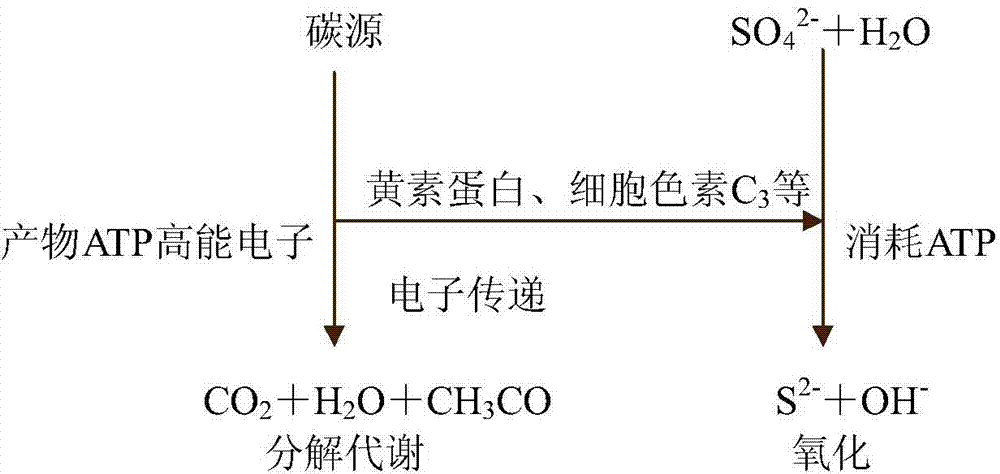

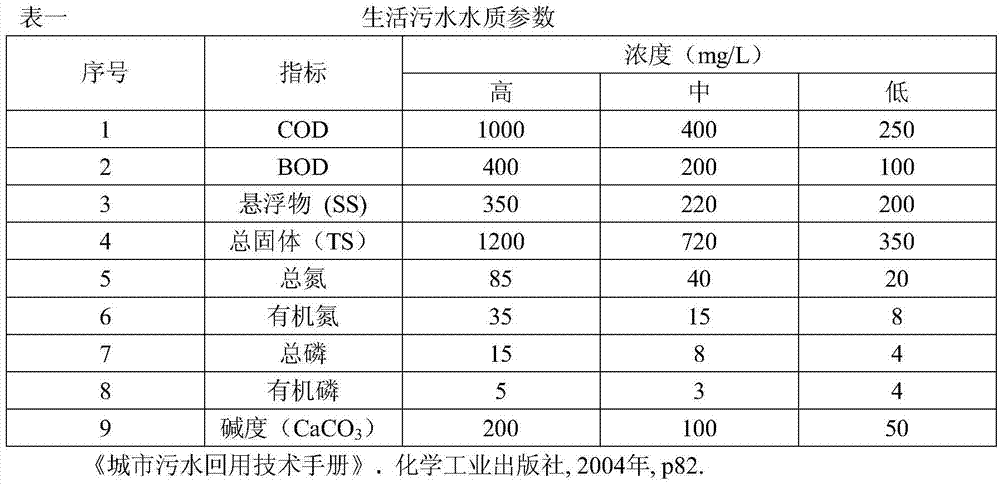

A technology for industrial wastewater and sulfate, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems that domestic sewage cannot meet the needs of high-concentration sulfate radical reduction, and meet the application conditions Harsh, solve economic problems, easy to absorb and utilize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

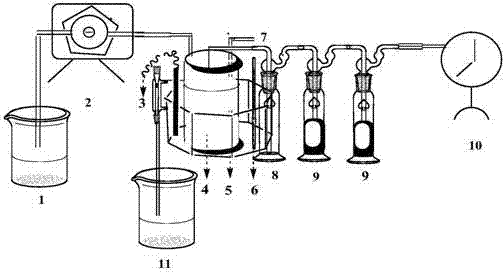

Method used

Image

Examples

Embodiment 1

[0045] a. Put the soybean meal in a container and let it ferment naturally for 3 days.

[0046] b. The fully fermented soybean meal is added into domestic sewage at a solid-liquid ratio of 1:20 to grind into a composite carbon source suitable for SRB growth;

[0047] c. Take a mine in Ji'an Ji'an with pH=1.56 containing 500mg·L -1 Fe 2+ Of acid sulfate wastewater 1L, its sulfate concentration [SO 4 2- ]3g·L -1 , Add SRB bacteria liquid in the ratio of 10+1;

[0048] d. The above-mentioned acid containing SRB containing Fe 2+ Sulfate wastewater and composite carbon source solution are based on the ratio of carbon to sulfur [SO 4 2- ] / [COD] is 1:2 and mixed, the sulfate concentration is 198.73mg·L -1 , Fe 2+ Concentration 3.83mg·L -1 And pH 5.80, flow into the anaerobic moving bed biofilm reactor with effective volume of 7.5L at a flow rate of 0.2L per hour;

[0049] e. The effluent is recycled, and the treated wastewater is passed into an anaerobic moving bed reactor with an effective v...

Embodiment 2

[0052] a. Put the corn germ meal in a container and let it ferment naturally for 4 days.

[0053] b. The fully fermented corn germ meal is added to domestic sewage at a solid-to-liquid ratio of 1:30 to grind to a size below 180 meshes to make a composite carbon source suitable for SRB growth;

[0054] c. Take a mine in Liaoning with pH=2.07 containing 1000mg·L -1 Cu 2+ Of acid sulfate wastewater 1L, its sulfate (SO 4 2- ) Concentration 8g·L -1 , Add SRB bacteria liquid in the ratio of 10+3;

[0055] d. The above-mentioned acid containing SRB containing Cu 2+ Sulfate wastewater and composite carbon source solution are based on the ratio of carbon to sulfur [SO 4 2- ] / [COD] is 1:3 and mixed, the sulfate concentration is 259.36mg·L -1 , Cu 2+ Concentration 1.37mg·L -1 And pH 6.07, flow into an anaerobic moving bed reactor with an effective volume of 7.5L at a flow rate of 0.3L per hour;

[0056] e. The effluent is recycled, and the treated wastewater is passed into an anaerobic moving bed...

Embodiment 3

[0059] a. Put the soybean meal in a container and let it ferment naturally for 5 days.

[0060] b. The fully fermented soybean meal is added into domestic sewage at a solid-to-liquid ratio of 1:40 to grind into a composite carbon source suitable for SRB growth;

[0061] c. Take a mine in Tonghua, Jilin with pH=2.0 containing 3000mg / L Zn 2+ Of acid sulfate wastewater 1L, its sulfate (SO 4 2- ) Concentration 15g·L -1 , Add SRB bacteria liquid in the ratio of 10+5;

[0062] d. The above-mentioned acid containing SRB containing Zn 2+ Sulfate wastewater and composite carbon source solution are based on the ratio of carbon to sulfur [SO 4 2- ] / [COD] is 1:2.5 after mixing, the measured sulfate concentration is 5227.24mg·L -1 , Zn 2+ Concentration 22.24mg·L -1 And pH 6.25, flow into an anaerobic moving bed reactor with an effective volume of 7.5L at a flow rate of 0.4L per hour;

[0063] e. The effluent is recycled, and the treated wastewater is passed into an anaerobic moving bed reactor with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap