Manufacturing method of filter grating for removing scattered x-rays

A manufacturing method and line absorption technology, which are applied in the fields of radiation diagnostic diaphragms, echo tomography, radiation/particle processing, etc., can solve problems such as difficulty in maintaining mechanical strength and large aspect ratio, and achieve high throughput and high resolution. and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] Hereinafter, the present invention will be specifically and described in detail by citing its embodiments, but the present invention is not limited to these specific examples, and extended or extended examples are also included as long as it is based on the essence of the present invention. That is, the present invention is not limited to the above-described embodiments or modifications, and it goes without saying that various modifications, design changes, and the like that do not depart from the scope of the technical idea of the present invention are included in the technical scope thereof.

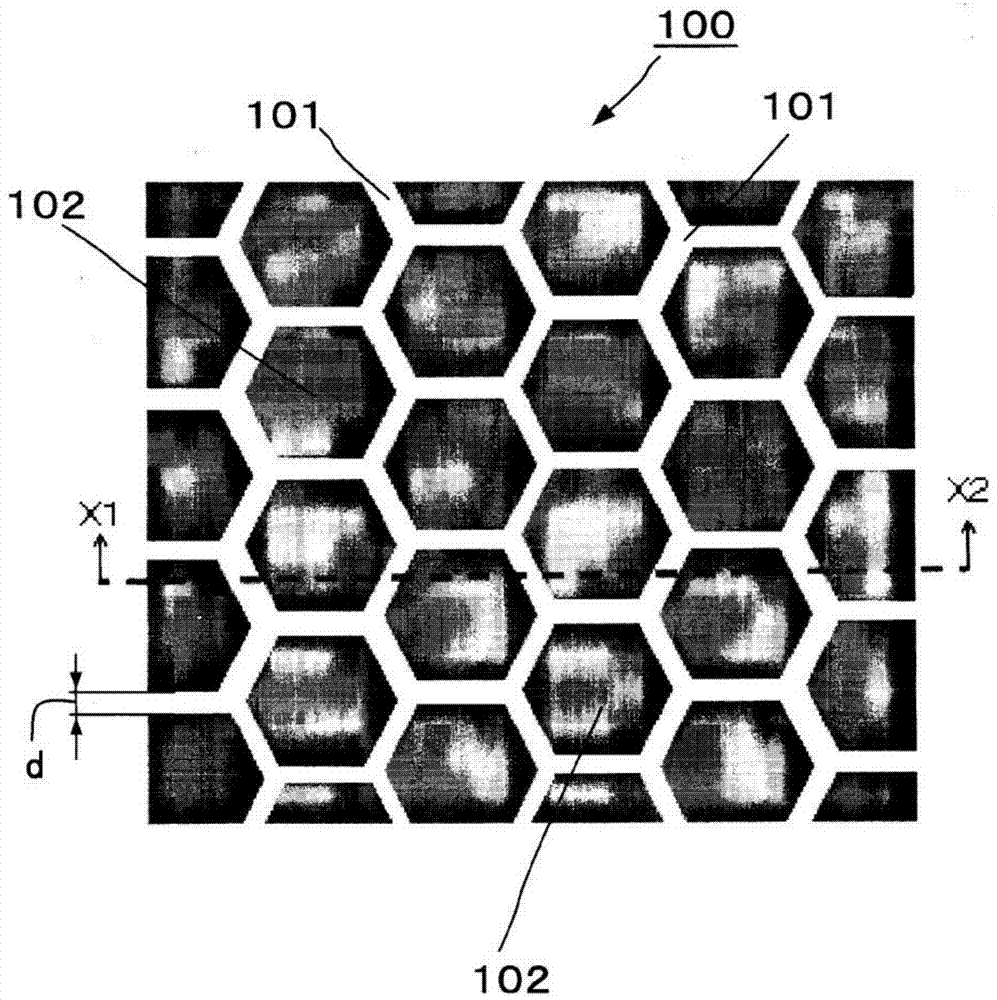

[0114] Figure 1A It shows a schematic enlarged upper part view for explaining one of preferable examples of the filter grating for removing scattered X-rays manufactured by the manufacturing method of the present invention.

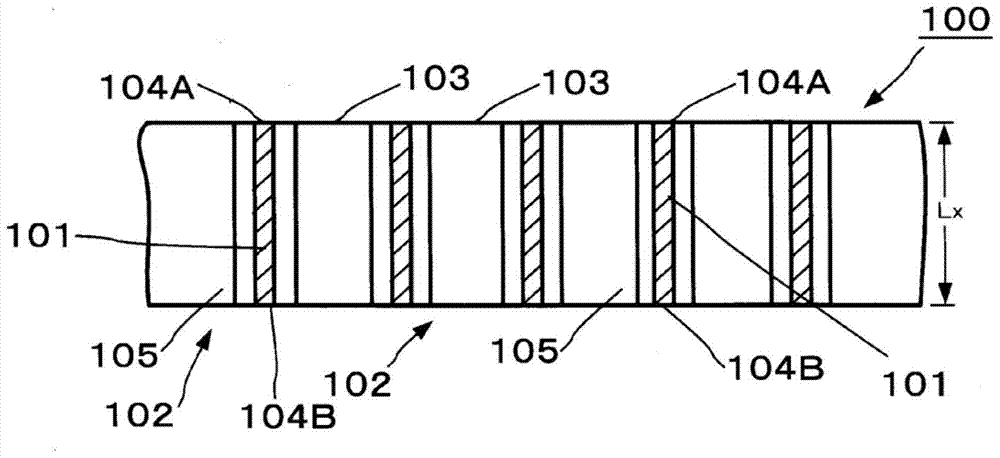

[0115] Figure 1B expressed in Figure 1A In the case where the part indicated by the dashed-dotted line X1-X2 is cut, it is a schematic enlarged cut-aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com