NOx purification triple-effect catalyst for working condition of excessive equivalent combustion intermittent oxygen and preparation method thereof

A three-way catalyst, intermittent technology, applied in the field of automobile exhaust gas purification, can solve the problems of restoring TWC oxygen storage capacity, NOx leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

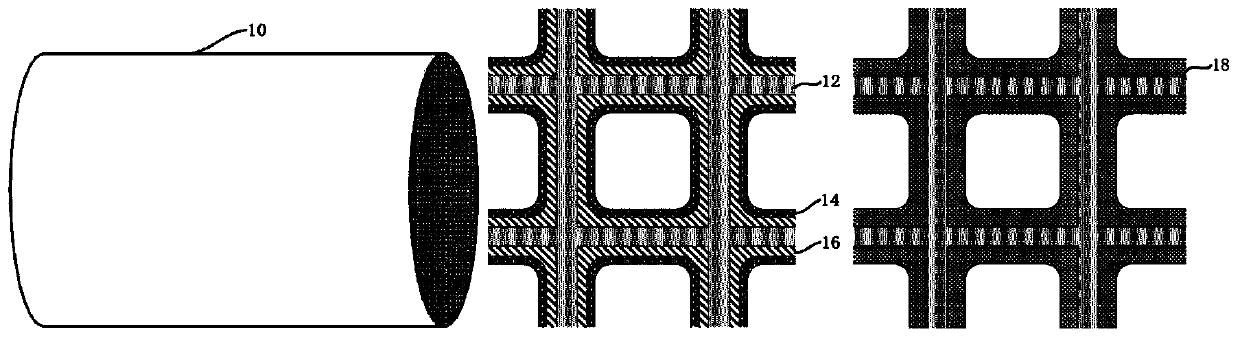

[0027] Example 1: Preparation of NOx storage catalytic material and application of the first coating

[0028] with barium acetate (BaCO 3 ), potassium carbonate (K 2 CO 3 ) as the precursor, ammonium carbonate ((NH 4 ) 2 CO 3 ) is a precipitating agent, and the precipitation method is used to prepare K 2 CO 3 -BaCO 3 -Al 2 o 3 powder, dried at 150°C and calcined at 700°C for 2 hours, the obtained K 2 CO 3 -BaCO 3 -Al 2 o 3 K in powder 2 CO 3 、BaCO 3 The mass percentages are 8% and 24% respectively. with K 2 In terms of O and BaO, the mass percentages are 5.45% and 18.65% respectively.

[0029] K 2 CO 3 -BaCO 3 -Al 2 o 3 and CeO 2 The powder is mixed at a mass ratio of 8:2, added with deionized water to make slurry, and the pH value is adjusted to 5-7 by nitric acid.

[0030] Add tetraammonium platinum acetate, the platinum loading is 50g / ft 3 .

[0031] Adjust the solid content of the slurry and the grinding particle size to an appropriate value to ...

Embodiment 2

[0036] Embodiment 2: Preparation of three-way catalytic material and second coating coating

[0037] The rare earth oxide, lanthanum-modified alumina and low-temperature alumina are mixed at a mass ratio of 5:4.5:0.5, and deionized water is added to make slurry.

[0038] Add palladium nitrate and rhodium nitrate aqueous solution, palladium and rhodium loading are 2g / ft respectively 3 , 8g / ft 3 .

[0039] Adjust the pH value, solid content, and abrasive particle size of the slurry to an appropriate value to ensure the firmness of the coating and the control of the coating height, and apply it on the surface of the coating of the NOx storage catalytic material to form the second layer, as the outer layer, the coating amount 100g / L.

[0040] The composition of the components in the second coating material is specified in Table 2.

[0041] Table 2

[0042] Coating Composition PD Rh CeO 2

[0043] Dry at 180°C and bake at 500°C for 2 hours.

Embodiment 3

[0044] Embodiment 3: Mixed coating of multiple catalytic materials

[0045] The NOx storage catalytic material (dry material) in Example 1, the three-way catalytic material (dry material) in Example 2, and the Pd modified molecular sieve material (dry material) were mixed at a mass ratio of 5:4:1.

[0046] The Pd modified molecular sieve material can be prepared by impregnation method, ion exchange method and other methods, and the loading amount (mass percentage) of Pd is 0.5%.

[0047] The catalytic material was dried at 150°C and calcined at 500°C for 2 hours to obtain a dry material.

[0048] The purpose of using dry material in practice is to prevent the active precious metals in different catalytic materials from migrating to the surface of other materials during the slurry mixing process.

[0049] Mix various catalytic materials fully and evenly by means of rubber mill, adjust the pH value, solid content, and grinding particle size of the slurry to a suitable value, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com