Preparation method of high-permeability carbon paper for fuel cell

A fuel cell and air permeability technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as low surface tension, increased hydrophilicity of carbon materials, and damage to water-air balance, and achieve surface resistance and contact resistance. Enhanced conductivity and hydrophobicity, enhanced storage and release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

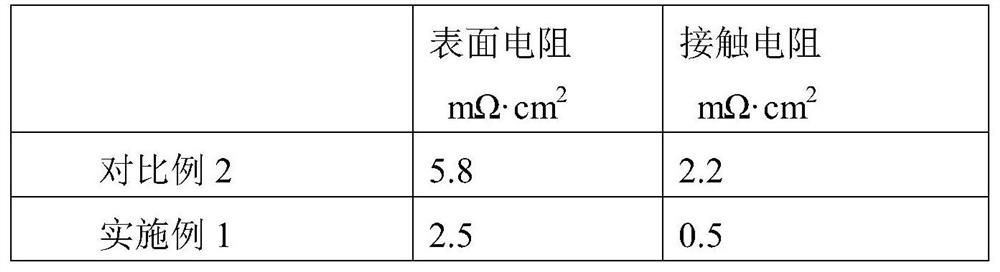

Embodiment 1

[0021] A preparation method of highly air-permeable carbon paper for fuel cells, comprising the following steps:

[0022] S1: Soak 2cm×2cm blank carbon paper in PTFE solution, repeat the above steps to prepare carbon paper with 15% PTFE content;

[0023] S2: Ce(NO 3 ) 3 .6H 2 O, ZrO(NO 3 ) 2 .2H 2 O and Y (NO 3 ) 3 ·6H 2 0 was dissolved in water, and nano-TiN with a diameter of 400-600nm was added, the mass fraction added was 5%, after continuous stirring, ammonia water was slowly added to the solution, and after adjusting the pH=10-11, obvious deposits were formed. After suction filtration, washing and drying, the precipitate is calcined in a muffle furnace at 550° C. for 2.5 hours, and then the calcined precipitate is pulverized by a planetary ball mill. The particle size of the precipitate is 0.3-0.6 μm.

[0024] S3: Ce prepared from S2 0.6 Y 0.1 Zr 0.3 o 2 / TiN and carbon powder, PTFE emulsion, according to 0.1mg / cm 2 、1mg / cm 2 and 10% of the added amount ar...

Embodiment 2

[0026] A preparation method of highly air-permeable carbon paper for fuel cells, comprising the following steps:

[0027] S1: Soak 2cm×2cm blank carbon paper in PTFE solution, repeat the above steps to prepare carbon paper with 5% PTFE content;

[0028] S2: Ce(NO 3 ) 3 .6H 2 O, ZrO(NO 3 ) 2 .2H 2 O and Y (NO 3 ) 3 ·6H 2 0 was dissolved in water, and nano-TiN with a diameter of 400-600nm was added, and the mass fraction added was 4%. After continuous stirring, ammonia water was slowly added to the solution, and after the pH was adjusted to 10-11, obvious deposits were formed. After suction filtration, washing and drying, the precipitate is calcined in a muffle furnace at 510°C for 3 hours, and then the calcined precipitate is pulverized by a planetary ball mill. The particle size of the precipitate is about 0.3-0.6 μm.

[0029] S3: Ce prepared from S2 0.2 Y 0.05 Zr 0.1 o 2 / TiN and carbon powder, PTFE emulsion, according to 0.15mg / cm 2 , 1.5mg / cm 2 and 12% of the ...

Embodiment 3

[0031] A preparation method of highly air-permeable carbon paper for fuel cells, comprising the following steps:

[0032] S1: Soak 2cm×2cm blank carbon paper in PTFE solution, repeat the above steps to prepare carbon paper with 5-15% PTFE content;

[0033] S2: Ce(NO 3 ) 3 .6H 2 O, ZrO(NO 3 ) 2 .2H 2 O and Y (NO 3 ) 3 ·6H 2 0 was dissolved in water, and nano-TiN with a diameter of 400-600nm was added, and the mass fraction added was 10%. After continuous stirring, ammonia water was slowly added to the solution, and after adjusting the pH=10-11, obvious deposits were formed. After suction filtration, washing and drying, the precipitate is calcined in a muffle furnace at 500-550°C for 2-3 hours, and then the calcined precipitate is pulverized by a planetary ball mill. The particle size of the precipitate is about 0.3-0.6 μm.

[0034] S3: Ce prepared from S2 0.8 Y 0.5 Zr 0.8 o 2 / TIN and carbon powder, PTFE emulsion, according to 0.05mg / cm 2 , 0.5mg / cm 2 and 7% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com