Switch magnetic flow arc-shaped permanent magnet motor

A technology of switching magnetic flux and permanent magnet motors, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc. It can solve the problems of low utilization rate of permanent magnets, low positioning accuracy, slow motion response, etc., and achieve Avoid high temperature demagnetization, high positioning accuracy, and small electromagnetic influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

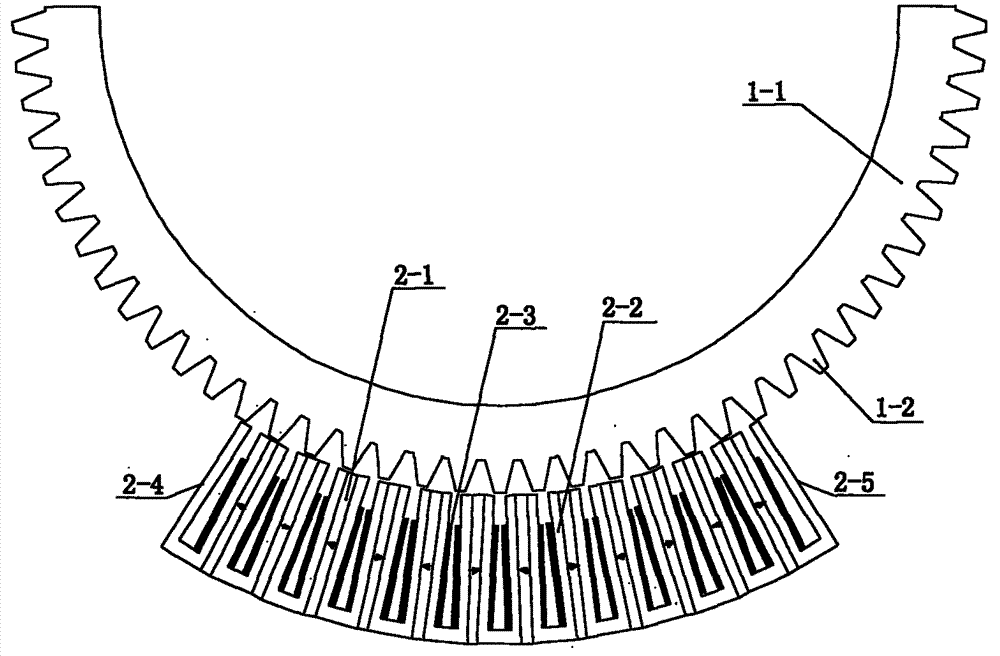

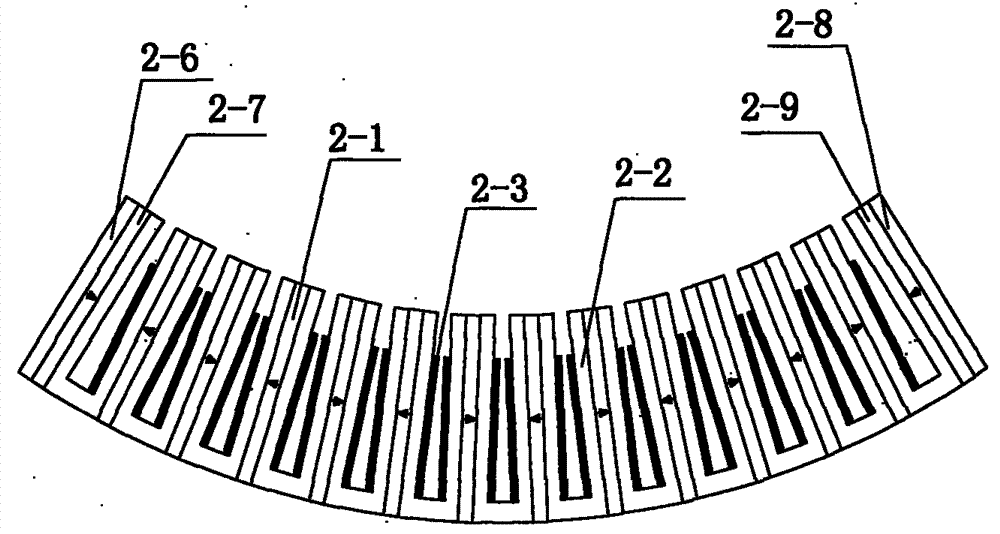

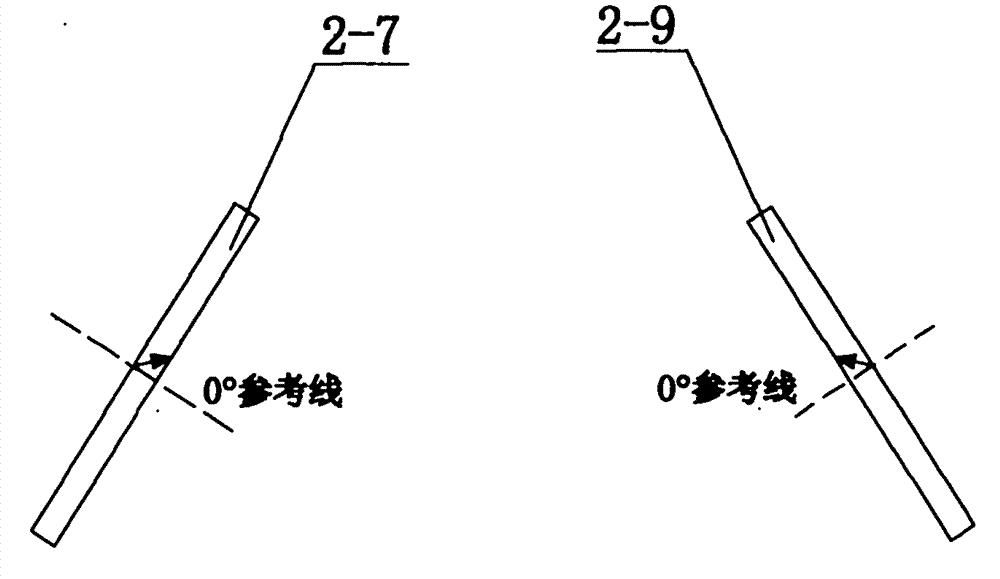

[0020] combine figure 1 This embodiment will be described. This embodiment includes a stator and a mover (1-1). The mover (1-1) is a semi-circular arc-shaped structure made of laminated silicon steel sheets, and several salient poles (1-2) of the same shape are evenly distributed along the circumference; the stator is an arc-shaped structure at a certain angle, composed of N pieces of complete U-shaped iron cores (2-2) and N-1 pieces of permanent magnets (2-1) are closely spaced in sequence. The magnetization direction of adjacent permanent magnets is opposite along the circumferential direction. The permanent magnets can be high-performance rare earth permanent magnets. Magnetic material; stator U-shaped iron core (2-2) is made of laminated silicon steel sheets, and concentrated armature winding (2-3) is placed in U-shaped groove (2-2); number of salient poles (1-2) of mover The number of U-shaped slots (2-2) of the stator is matched according to the mechanism of electromagn...

Embodiment 2

[0022] combine figure 1 To illustrate this embodiment, the difference from Embodiment 1 is that the windings placed in the U-shaped groove (2-2) are three-phase or more than three-phase.

Embodiment 3

[0024] combine figure 1 The present embodiment is different from the first embodiment in that the angle at which the mover (1-1) is larger than the stator is the scanning range of the motor, and the central angle of the stator can be designed according to the scanning range requirements of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com