Method for assisting in tailings restoration through ryegrass and planting ryegrass on restored land

A technology of ryegrass and rye, which is applied in the direction of soil preparation methods, botanical equipment and methods, applications, etc., can solve problems such as tailings environmental pollution, and achieve the effects of strong operability, promoting plant growth, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: A method of using ryegrass as green manure to assist tailings ecological restoration.

[0034] Plow and level the tailings at a depth of 20cm;

[0035] Collect fresh ryegrass grown to the flowering stage, and cut the fresh ryegrass into pieces of 4 cm to form ryegrass green manure;

[0036] According to the weight ratio of the dry weight of the ryegrass green manure to the air-dried weight of the tailings, the ryegrass green manure is spread on the plowed and leveled tailings land, and the spreading amount of the ryegrass green manure is 1% to 5%. Fully mix the ryegrass green manure and the tailings to form a flat planting ground.

[0037] Ryegrass green manure can also be applied in conjunction with other fertilizers or amendments.

[0038] The ryegrass green manure is applied in combination with fertilizers, 20-25 kg of calcium magnesium phosphate fertilizer is used as the base fertilizer, and 4-8 kg of urea is applied per mu, and it is applied at the s...

Embodiment 2

[0040] Example 2: Ryegrass assisted tailings restoration and method for planting ryegrass on restoration ground

[0041] The specific sowing method is:

[0042] a. Seed treatment: sterilize the ryegrass seeds with a disinfectant, soak the seeds, and accelerate germination;

[0043] b. Sowing: In the planting area, build ridges with a width of 1 m, the distance between the ridges is about 0.3~0.5 m, and the height of the ridges is 8~10 cm. After the ridge surface is leveled, the row spacing is 0.2~0.3 m. About m, the depth of the sowing ditch is 4-6 cm, and the ryegrass seeds are sown in the sowing ditch by drill, the sowing rate is 2-3 kg per mu, and the surface of the sowing ditch is covered with 2-3 cm of soil after sowing. No human intervention is required during ryegrass growth.

[0044] c. Regular stubble harvesting and returning to the field: the first crop of ryegrass grows to about 50 days and the stubble is harvested. The stubble of the ryegrass is about 5 cm, and...

Embodiment 3

[0046] Example 3: Method for planting ryegrass on repaired lead-zinc tailings

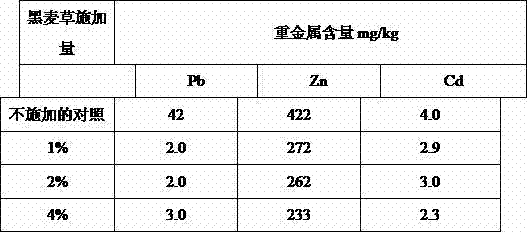

[0047] After plowing and leveling the surface of the lead-zinc tailings to a depth of 20 cm, the fresh ryegrass that has grown to the flowering stage is cut into pieces of about 3 cm and then fully mixed with the tailings. The application rates of ryegrass were 1%, 2% and 4% (dry weight of ryegrass / dry weight of tailings). Then plant ryegrass. The growth process of ryegrass does not require human intervention, and management such as planting and harvesting is carried out in accordance with local conventional methods. The ryegrass was harvested after 50 days of growth, and samples of ryegrass and tailings were collected to analyze some of their physical and chemical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com