Electric heating regeneration pretreatment device and electric heating regeneration pretreatment method for activated carbon

A technology of pretreatment device and heating device, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of reducing the resistance of saturated activated carbon, incapable of low-voltage electrothermal regeneration, etc., so as to improve the efficiency and improve the tunnel effect. probability, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

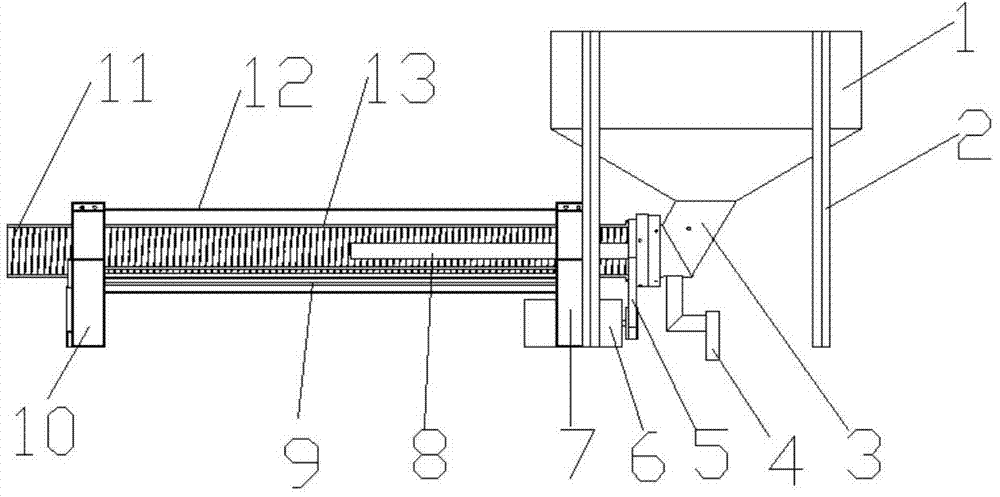

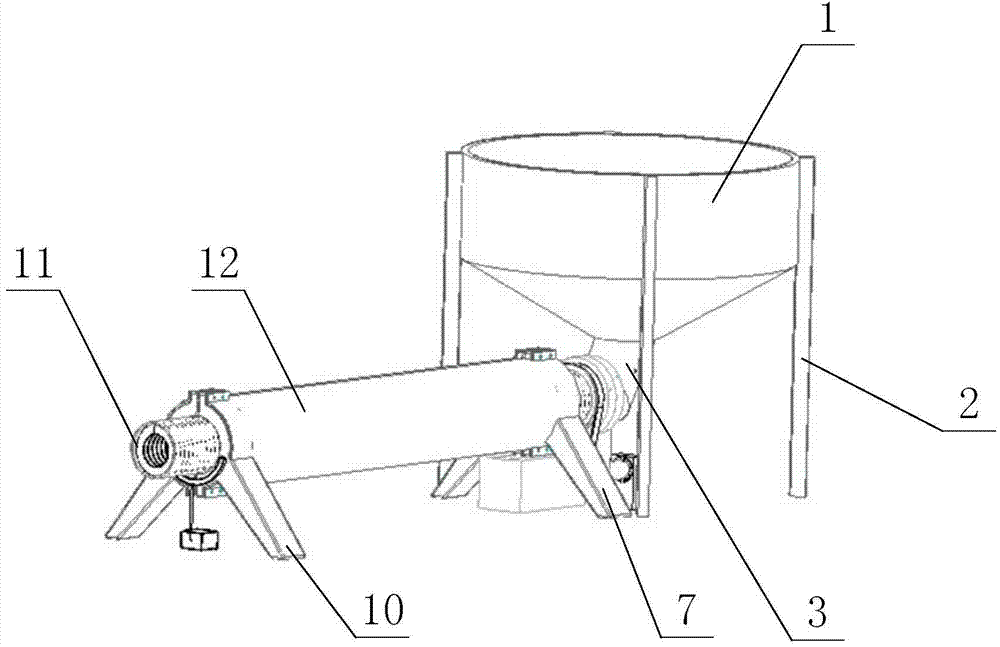

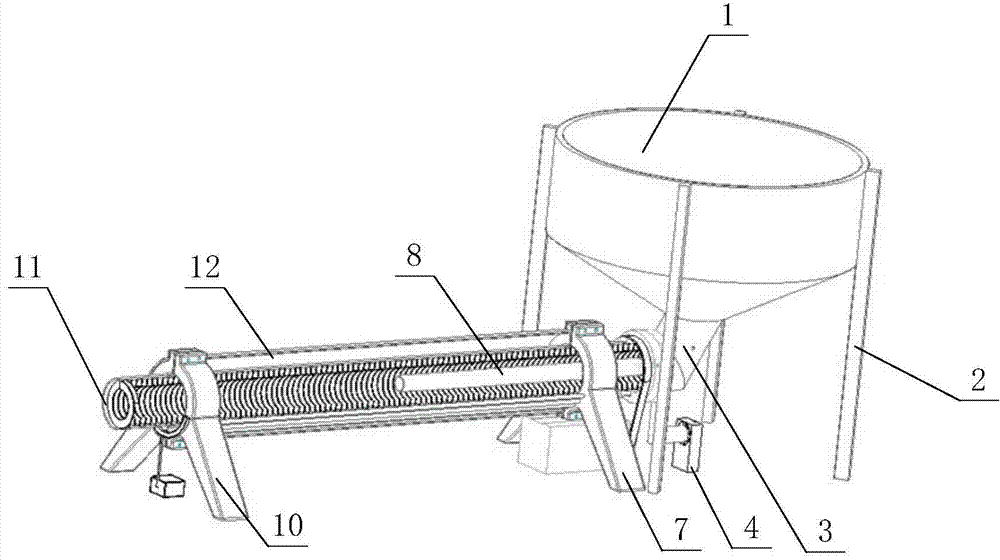

[0051] Such as figure 1 , 2 As shown in and 3, the activated carbon electric heating regeneration pretreatment device includes a feed dish 1 and a center pipe 13; the feed dish 1 is fixed on four support columns 2; One end communicates; the other end of the inclined channel 3 communicates with the central tube 13; the angle between the inclined channel 3 and the horizontal direction is 45°; the two ends of the central tube 13 are respectively supported on the first support frame 7 and the second support frame 10 by bearings Above; the inner wall of the central tube 13 is tapped with a full thread, and a temperature measuring probe is provided; the heating device 9 is arranged on the outer wall of the bottom of the central tube 13; the heating device 9 is a resistance wire; the heat preservation shell 12 is sleeved on the central tube 13 and the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com