Automatic cleaning method for engine cylinder cover

An engine cylinder head and automatic cleaning technology, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, cleaning methods using liquids, etc., can solve low drying efficiency, insufficient cleaning pertinence, poor cleaning efficiency and effect, etc. problem, to achieve the effect of good cleaning pertinence, good cleaning effect and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

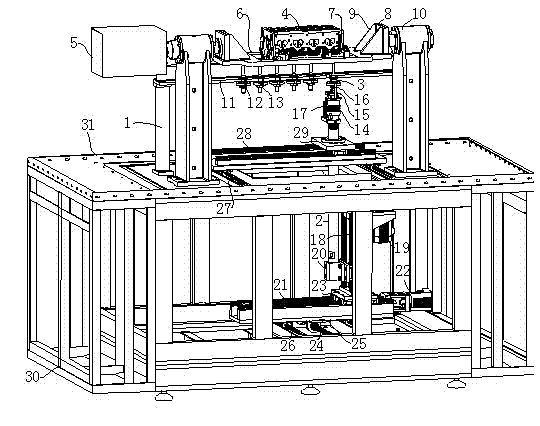

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] An automatic cleaning method for the engine cylinder head, which is automatically controlled by an automatic control system during cleaning, so that the nozzle moves under the engine cylinder head driven by a three-dimensional moving device and sprays out cleaning liquid or compressed air to clean the engine cylinder head. That is, in the cleaning process, the two ends of the engine cylinder head are installed on the frame through the horizontally arranged rotating shaft, and the engine cylinder head is driven to rotate by the rotating servo motor, and then a cleaning workpiece is added on the basis of three-dimensional motion cleaning to rotate itself The dimensions make it produce the effect of simulating manual cleaning and improve cleaning efficiency. Further, after cleaning, the cylinder head of the engine is driven to rotate by the rotating servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com