High-barrier material for red wine BIB packaging

A high barrier and red wine technology, applied in the field of liquid food packaging, can solve the problems of high cost of EVOH products and expensive investment, and achieve the effects of reducing the risk of bag breakage, ensuring safety, and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

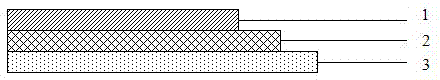

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] combine figure 1 , the barrier layer 2 is a modified polyvinyl alcohol (PVA) coating solution, and the modified PVA coating solution is coated on the surface of the co-extruded 5-filament polyethylene (PE) layer 3. After aging, the composite glue and the composite layer 1 Composite, then at 55 o C ripening for 48 h.

[0016] The composite layer 1 is a biaxially stretched BOPP film, and the polyethylene co-extruded layer 3 is a 5-filament polyethylene co-extruded film with heat-sealing properties.

[0017] The oxygen transmission rate test before and after kneading is carried out, and the data are as follows:

[0018] Before kneading: 0.33 mL / m 2 ·24h·0.1MPa; after kneading: 0.63 mL / m 2 ·24h·0.1MPa.

[0019] In terms of mechanical strength performance test, the data are as follows:

[0020] Tensile strength, longitudinal: 74.2 MPa; transverse: 77...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com