Method for extracting high-purity oleuropein from jasminum grandiflorum

A technology of oleuropein and frangipani is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., and can solve the problem of low content of oleuropein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

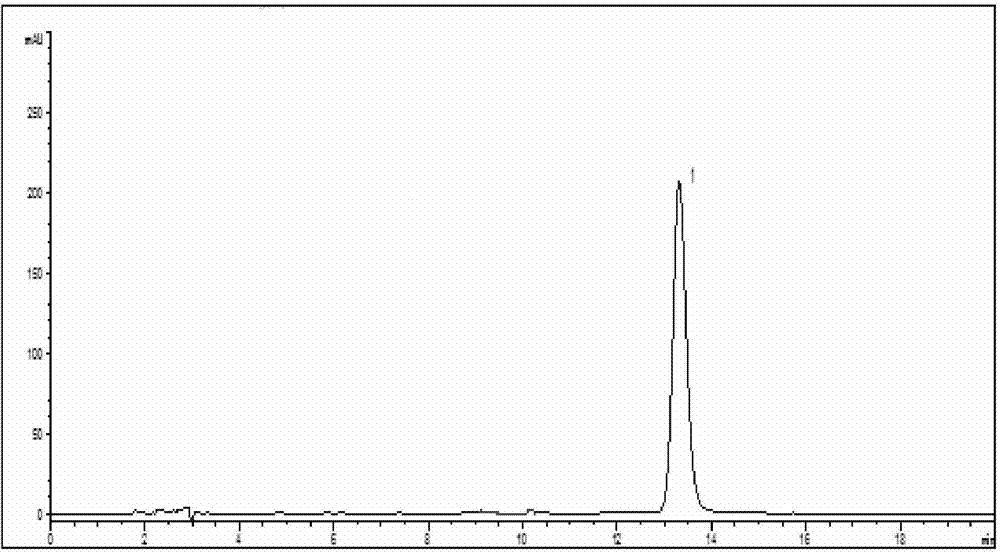

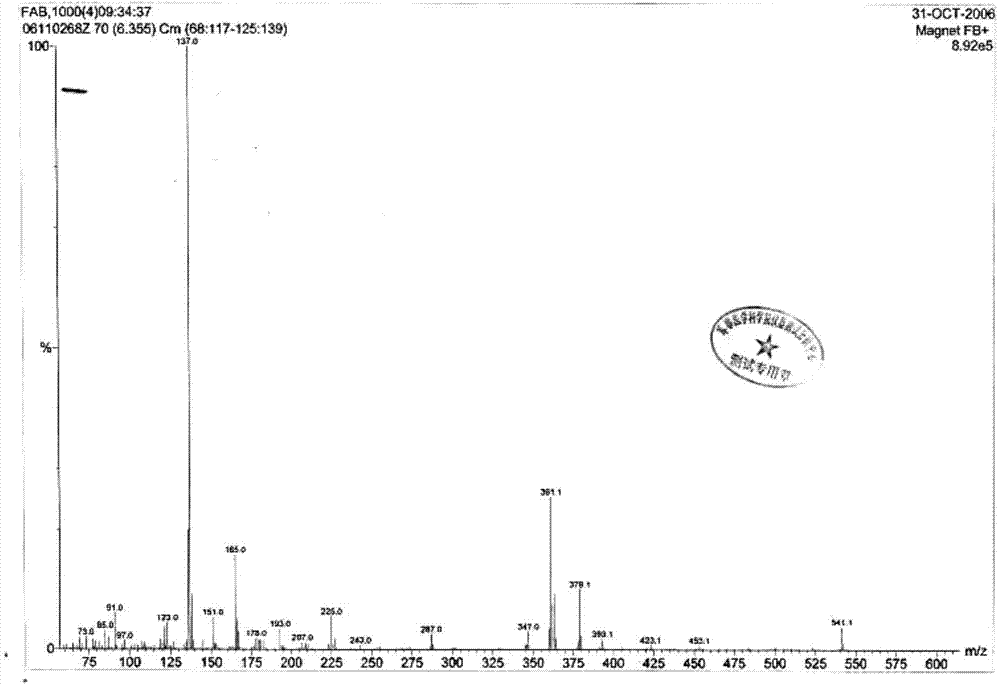

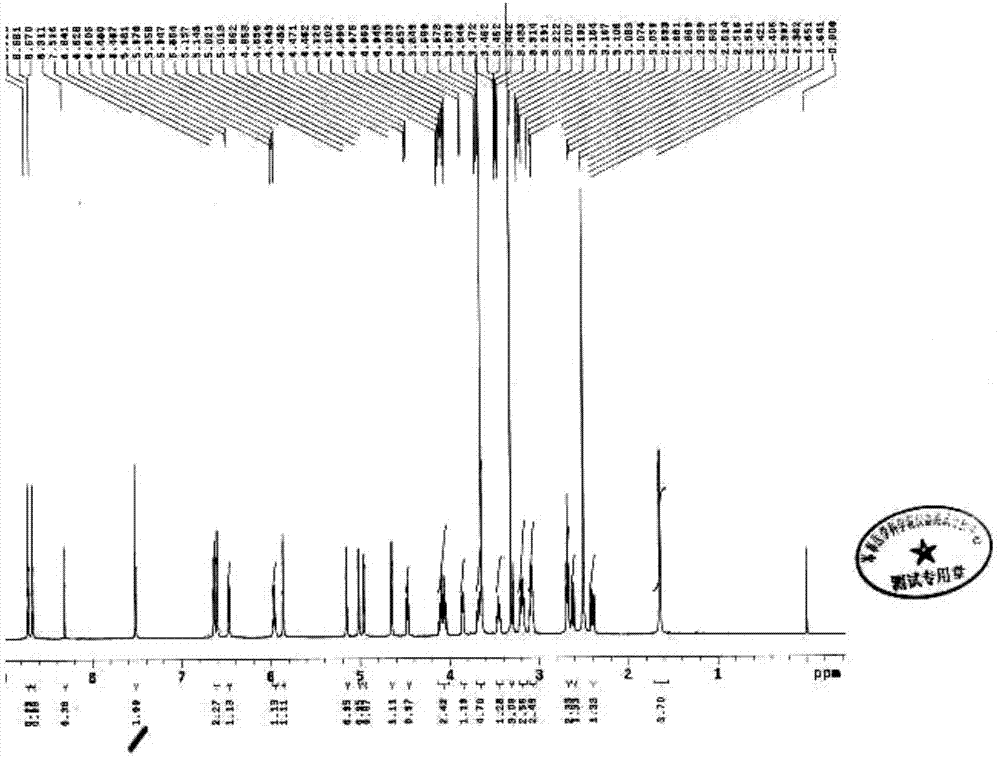

Image

Examples

Embodiment 1

[0164] Example 1: Extracting high-purity oleuropein from frangipani

[0165] The implementation steps of this embodiment are as follows:

[0166] A. Ethanol aqueous leaching

[0167] According to the weight ratio of frangipani flower buds to 60% ethanol aqueous solution by weight of 1:12, the dry frangipani flower bud raw materials with a water content of 2.0% by weight are soaked in ethanol aqueous solution at room temperature for 3 times, each time for 50h, The extracts obtained each time are filtered, the filtrates are combined, and then concentrated and dried at a temperature of 46°C to obtain frangipani extract M 1 ;

[0168] B. Macroporous resin column adsorption

[0169] Macroporous resin pretreatment: The XDA-16 macroporous resin sold by Xi'an Lanxiao Technology New Materials Co., Ltd. is soaked in 95% ethanol aqueous solution by weight for 22 hours, then wet-packed, and then used 95% ethanol by weight Elute with aqueous solution until the effluent is mixed with wate...

Embodiment 2

[0176] Example 2: Extracting high-purity oleuropein from frangipani

[0177] The implementation steps of this embodiment are as follows:

[0178] A. Ethanol aqueous leaching

[0179] According to the weight ratio of frangipani flower buds and 55% ethanol aqueous solution by weight of 1:11, the dry frangipani flower bud raw materials with a water content of 1.9% by weight are soaked in ethanol aqueous solution at room temperature for 3 times, each time for 47h, The extracts obtained each time are filtered, the filtrates are combined, and then concentrated and dried at a temperature of 49°C to obtain frangipani extract M 1 ;

[0180] B. Macroporous resin column adsorption

[0181] Macroporous resin pretreatment: The HPD-100 type macroporous resin sold by Cangzhou Baoen Adsorption Material Technology Co., Ltd. is soaked in 90% ethanol aqueous solution by weight for 25 hours, then wet-packed, and then used 90% ethanol aqueous solution by weight Elute until the effluent is mixe...

Embodiment 3

[0188] Example 3: Extracting high-purity oleuropein from frangipani

[0189] The implementation steps of this embodiment are as follows:

[0190] A. Ethanol aqueous leaching

[0191] According to the weight ratio of frangipani flower buds to 65% by weight ethanol aqueous solution of 10:1, the dry frangipani flower bud raw materials with a water content of 1.6% by weight are soaked in ethanol aqueous solution at room temperature for 4 times, each time for 46 hours, The extracts obtained each time are filtered, the filtrates are combined, and then concentrated and dried at a temperature of 50°C to obtain frangipani extract M 1 ;

[0192] B. Macroporous resin column adsorption

[0193] Macroporous resin pretreatment: XDA-1 type macroporous resin sold by Xi'an Lanxiao Technology New Materials Co., Ltd. is soaked in 92% ethanol aqueous solution by weight for 26 hours, then wet packed, and then used 92% ethanol by weight Elute with aqueous solution until the effluent is mixed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com