Glass fiber reinforced plastic

A glass fiber and reinforced plastic technology, applied in the field of glass fiber reinforced plastics, can solve the problems of large differences in thermal expansion coefficient, failure stress, strength, corrosion resistance and weather resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

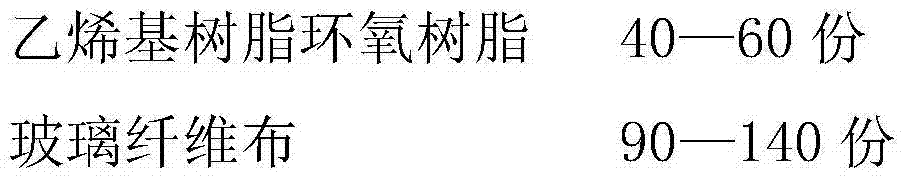

[0017] The glass fiber reinforced plastic of the present invention comprises the following components by weight:

[0018]

[0019] The weight ratio of combined low-shrinkage additive is 3 parts

[0020] The weight proportion of organic peroxy compound is 0.4 part

[0021] The preparation process is as follows: Step 1: Add coupling agent, combined low-shrinkage additive and organic peroxygen compound to the dispersant and disperse evenly, then add it to the vinyl resin epoxy resin, then add chopped fibers and stir evenly to obtain Hardener;

[0022] Step 2, laying the glass fiber cloth into the mold layer by layer, and placing the curing agent obtained in step 1 in the mold, at a temperature of 160 degrees Celsius and a vacuum (vacuum degree of 0.01-0.08MPa, preferably 0.03MPa) Carry out curing molding to obtain glass fiber reinforced plastic.

[0023] The glass fiber cloth is made of non-alkali glass fiber cloth. The characteristics of the non-alkali glass fiber cloth ar...

Embodiment 2

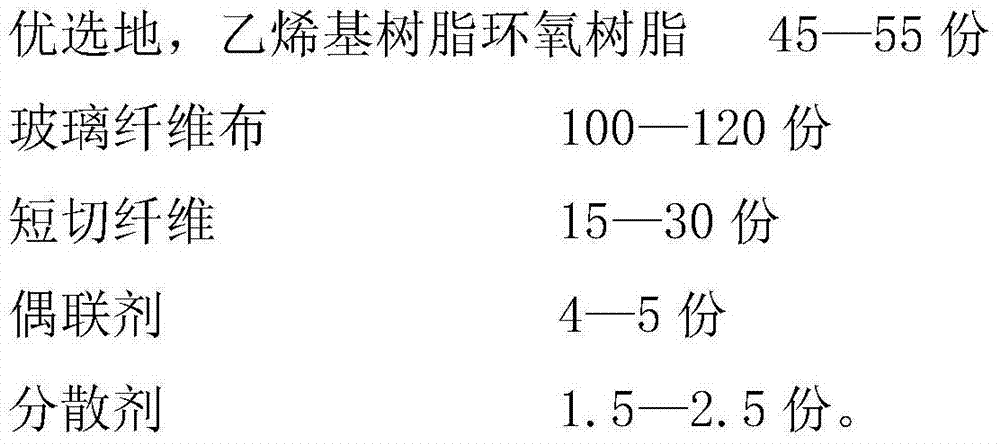

[0037] The glass fiber reinforced plastic of the present invention comprises the following components by weight:

[0038]

[0039]

[0040] The weight ratio of combined low-shrinkage additive is 4 parts

[0041] The weight proportion of organic peroxy compound is 0.5 part

[0042] The preparation process is, the preparation process is, step 1: add the coupling agent, combined low shrinkage additive and organic peroxygen compound to the dispersant and disperse evenly, then add it to the vinyl resin epoxy resin, and then add the chopped fiber And stir evenly to obtain curing agent;

[0043] Step 2, laying the glass fiber cloth into the mold layer by layer, and placing the curing agent obtained in the step 1 into the mold, at a temperature of 180 degrees Celsius and a vacuum degree of (0.01-0.08MPa, preferably 0.05MPa) Carry out curing molding to obtain glass fiber reinforced plastic.

[0044] What the glass fiber cloth adopts is alkali-free glass fiber cloth, and the ch...

Embodiment 3

[0058] The glass fiber reinforced plastic of the present invention comprises the following components by weight:

[0059]

[0060] The weight ratio of combined low-shrinkage additive is 5 parts

[0061] The weight proportion of organic peroxy compound is 0.6 part

[0062] The preparation process is, the preparation process is, step 1: add the coupling agent, combined low shrinkage additive and organic peroxygen compound to the dispersant and disperse evenly, then add it to the vinyl resin epoxy resin, and then add the chopped fiber And stir evenly to obtain curing agent;

[0063]Step 2: Lay the glass fiber cloth into the mold layer by layer, place the curing agent obtained in Step 1 into the mold, and cure it at a temperature of 200 degrees Celsius and a vacuum (0.01-0.08MPa, preferably 0.06MPa) Molded to obtain glass fiber reinforced plastic.

[0064] What the glass fiber cloth adopts is alkali-free glass fiber cloth, and the chopped fiber adopts chopped glass fiber, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com