Preparation method of inner core filling material for composite insulated cross arm

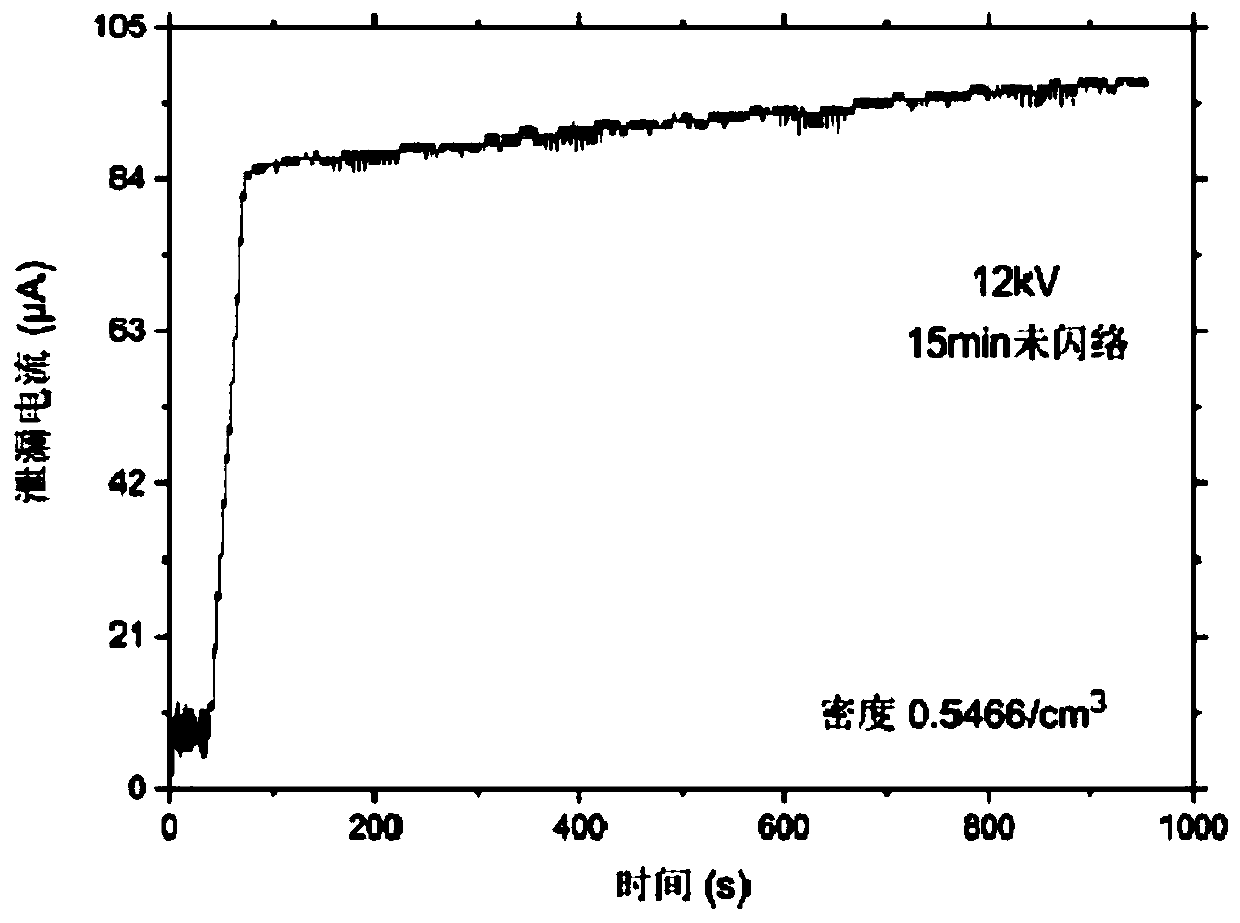

A technology of composite insulation and filling material, applied in the field of preparation of composite insulation cross arm inner core filling material, can solve the problems of poor weather resistance, low density insulation performance, reduced insulation characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

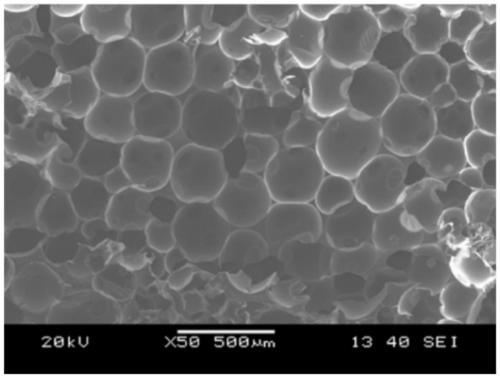

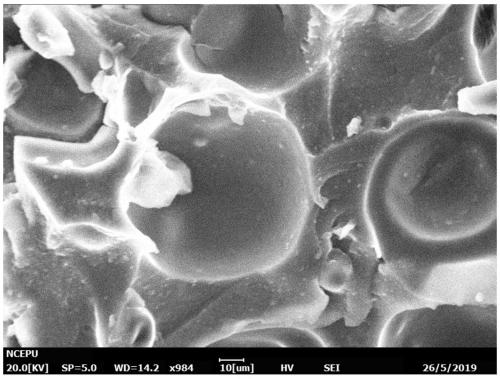

[0027] A method for preparing an inner core filling material for a composite insulating cross-arm, the method comprising the following steps:

[0028] a. Weigh 2.8 parts by weight of phenolic resin microspheres and 25 parts by weight of white material; after mixing the above raw materials, stir for 1 min at a rotating speed of 1000r / min to obtain a wetting mixture of hollow phenolic microspheres; the white material is polyethylene glycol 200 ;

[0029] b. After cleaning the composite insulating cross-arm mold, evenly spray the release agent;

[0030] c. Preheat the composite insulating cross-arm mold sprayed with release agent at 90°C for 24 hours;

[0031] d. take by weighing 10 parts by weight of the catalyzer and the hollow phenolic microbead wetting mixture obtained in step a; obtain the hollow phenolic microbead mixture, and the catalyzer is triethylenediamine;

[0032] e. Weigh 25 parts by weight of the black material, mix the black material with the hollow phenolic mi...

Embodiment 2

[0035] A method for preparing an inner core filling material for a composite insulating cross-arm, the method comprising the following steps:

[0036] a. Weigh 5.7 parts by weight of phenolic resin microspheres and 45 parts by weight of white material; after mixing the above raw materials, stir for 1 min at a rotating speed of 1400r / min to obtain a wetting mixture of hollow phenolic microspheres; white material is polyethylene glycol 200 ;

[0037] b. After cleaning the composite insulating cross-arm mold, evenly spray the release agent;

[0038] c. Preheat the composite insulating cross-arm mold sprayed with release agent at 100°C for 24 hours;

[0039] d. take by weighing 100 parts by weight of the catalyzer and the hollow phenolic microbead wetting mixture obtained in step a; obtain the hollow phenolic microbead mixture, and the catalyzer is dimethylaminoethyl ether;

[0040] e. Weigh 55 parts by weight of the black material, mix the black material with the hollow phenoli...

Embodiment 3

[0043] A method for preparing an inner core filling material for a composite insulating cross-arm, the method comprising the following steps:

[0044] a. Take by weighing 7.7 parts by weight of phenolic resin microspheres and 75 parts by weight of white material; after mixing the above-mentioned raw materials, stir for 3 min at a rotating speed of 1800r / min to obtain a wetting mixture of hollow phenolic resin microspheres; white material is polypropylene glycol 400;

[0045] b. After cleaning the composite insulating cross-arm mold, evenly spray the release agent;

[0046] c. Preheat the composite insulating cross-arm mold sprayed with release agent at 90-120°C for 24 hours;

[0047] d. take by weighing 10~200 parts by weight of the catalyzer and the hollow phenolic microbead wetting mixture obtained in the step a; obtain the hollow phenolic microbead mixture, and the catalyst is stannous octoate;

[0048] e. Weigh 75 parts by weight of black material, mix the black material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com