Cast-in-place construction process for inter-pile board wall between slide-resistant piles

A construction technology and anti-sliding pile technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high requirements for the prefabrication quality of the inter-pile slab and the construction quality of anti-sliding piles, the construction quality is not easy to guarantee, and the construction process is complicated, etc. problems, to achieve the effect of avoiding poor drainage, good drainage effect and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

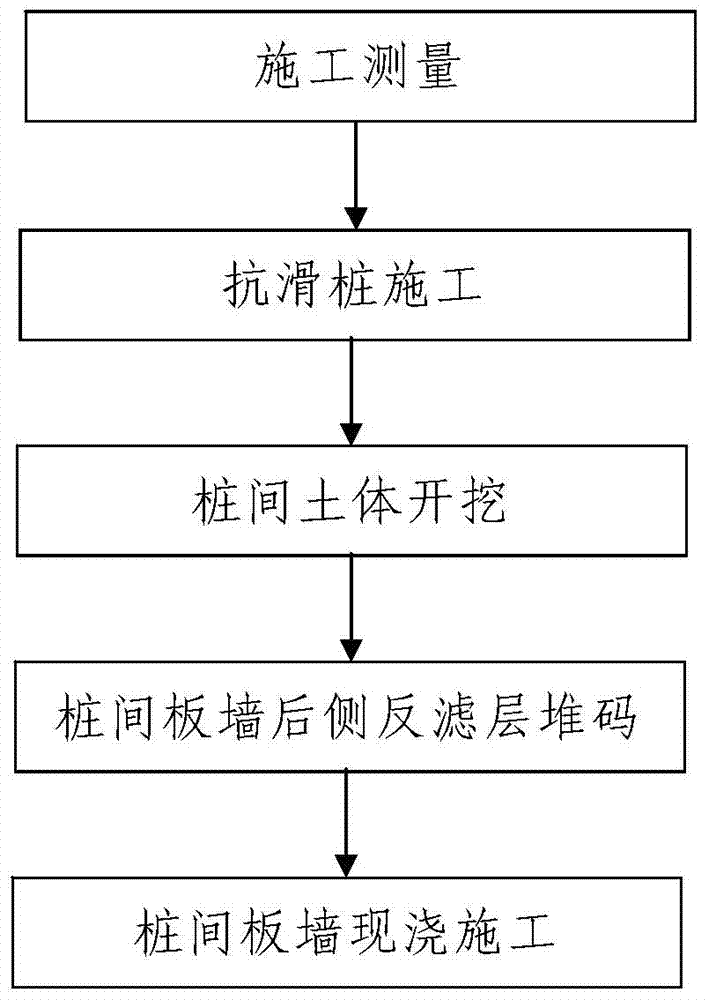

[0058] Such as figure 1 Shown is a cast-in-place construction technique for a slab wall between anti-slide piles, including the following steps:

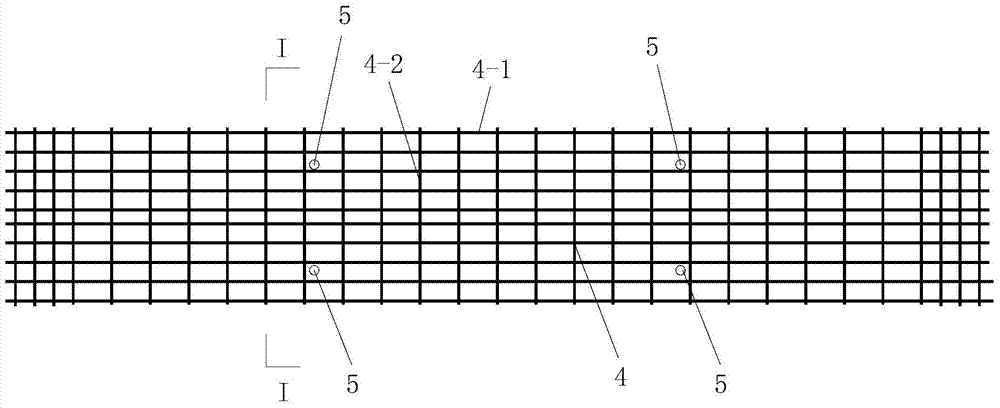

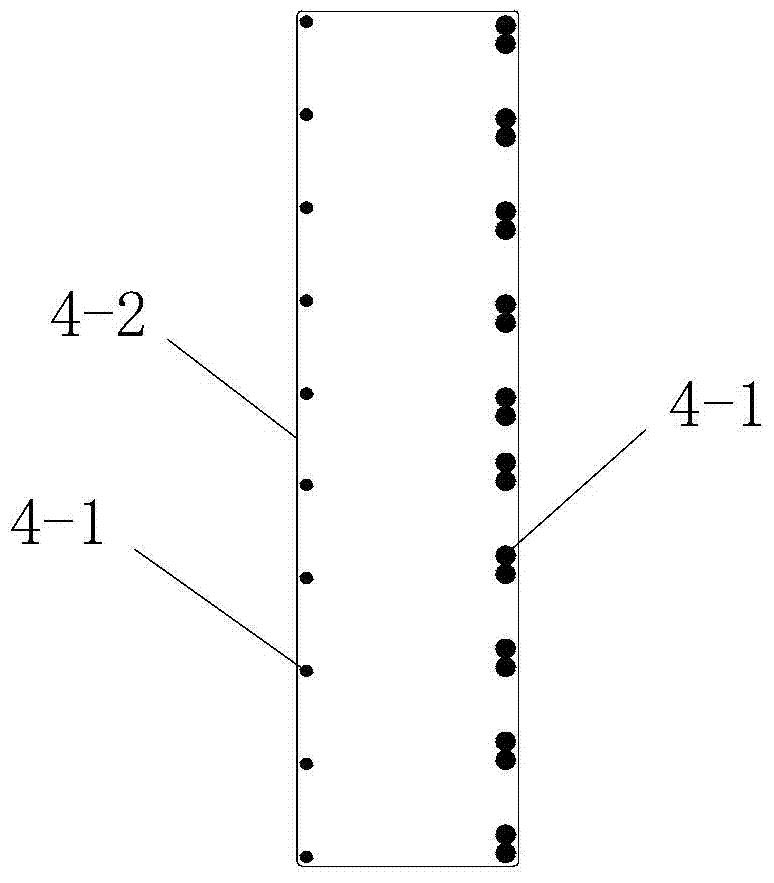

[0059] Step 1. Construction measurement: setting-out measurement is performed on the construction positions of the slab wall 6 between the constructed piles and the two anti-slide piles 1 located on both sides of the slab wall 6 between the constructed piles. The slab wall 6 between the constructed piles is a slab wall between two adjacent anti-slide piles 1, see image 3 and Figure 4 .

[0060] Step 2, anti-slide pile construction: according to the setting-out measurement results of the construction positions of the two anti-slide piles 1 in step 1, two described anti-slide piles 1 located on both sides of the slab wall 6 between the constructed piles The construction is carried out separately, and the two anti-slide piles 1 are reinforced concrete piles arranged vertically.

[0061] Step 3. Excavation of the soil between the ...

Embodiment 2

[0099] In this example, combined with Figure 5 and Figure 6 , the difference from Example 1 is: the pile slab wall 6 constructed in step 5 is located on the cutting and it is located inside the cutting slope 9; the pile slab wall 6 constructed is located between the two anti-slide piles 1 side and its length is the same as the distance between the inner sidewalls of the two anti-slide piles 1, the left and right sidewalls of the slab wall 6 between the constructed piles are respectively fastened and connected with the inner sidewalls of the two anti-slide piles 1 as One body; the inner foundations of the two anti-slide piles 1 are subgrades, the height of the inner foundations of the two anti-slide piles 1 is lower than the height of the outer foundations, and the inner foundations of the two anti-slide piles 1 are inner foundations The pile bodies of the two anti-slide piles 1 are divided into pile body exposed sections and pile body embedded sections with the inner founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com