Melamine base porous structure sandwich decorative sheet and preparation method thereof

A hole structure and decorative board technology, applied in building construction, covering/lining, construction, etc., can solve the problems of non-repairable decoration process, complicated decoration residual materials, non-recyclability, etc., to save sand and cement, easy to operate and Construction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

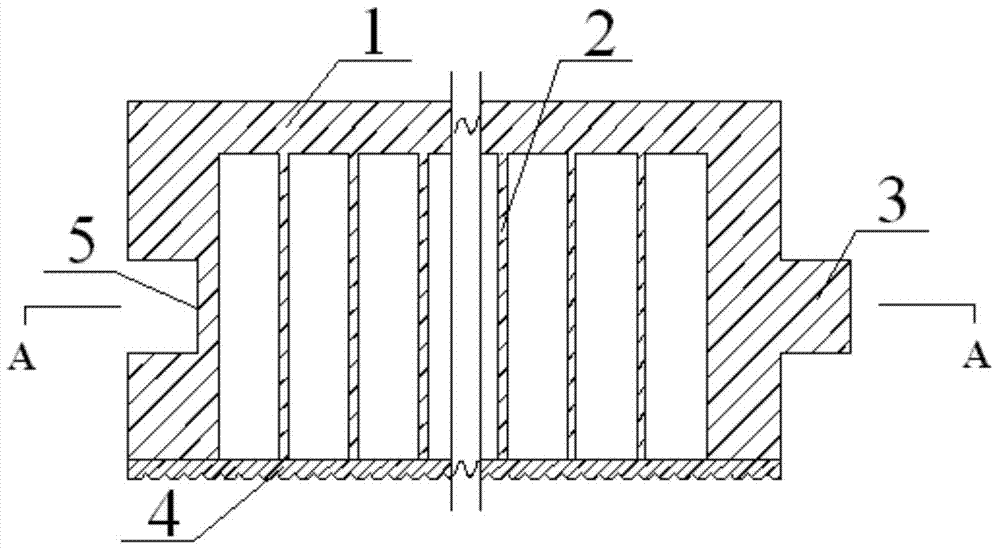

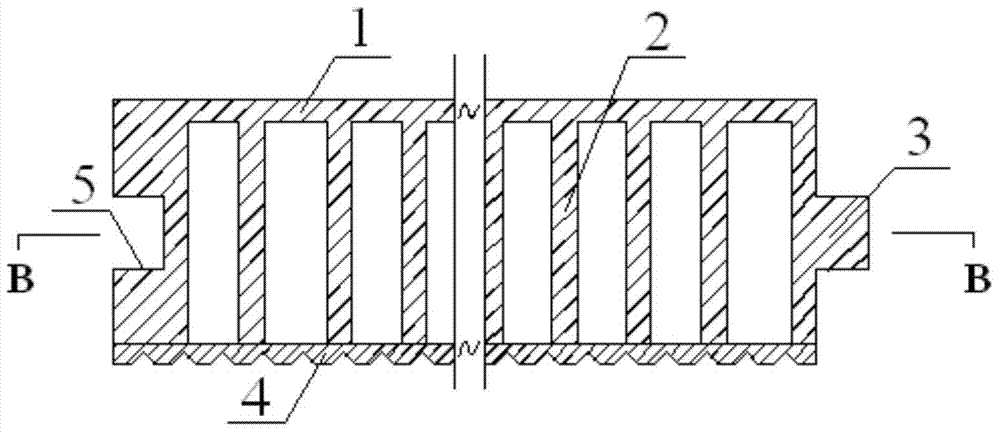

[0018] Specific implementation mode one: combine Figure 1 to Figure 8 , this embodiment is a melamine-based porous structure sandwich decorative panel, which is composed of a decorative upper panel 1, a porous sandwich structure 2, a protrusion 3 connected between the panels, a decorative lower panel 4 and a groove 5 connected between the panels, The decorative upper panel 1, the porous sandwich structure 2, the protrusions 3 connected between the panels and the grooves 5 connected between the panels are integrally formed by a hot press forming method to form a whole. The decorative lower panel 4 The upper surface is connected with the porous sandwich structure 2 by secondary hot pressing technology, and the lower surface of the decorative lower panel 4 is corrugated protrusions, dot-like protrusions or strip-like protrusions.

[0019] The combination of the melamine-based porous structure sandwich decorative panels in this embodiment can adopt a slot-type structure, or a spl...

specific Embodiment approach 2

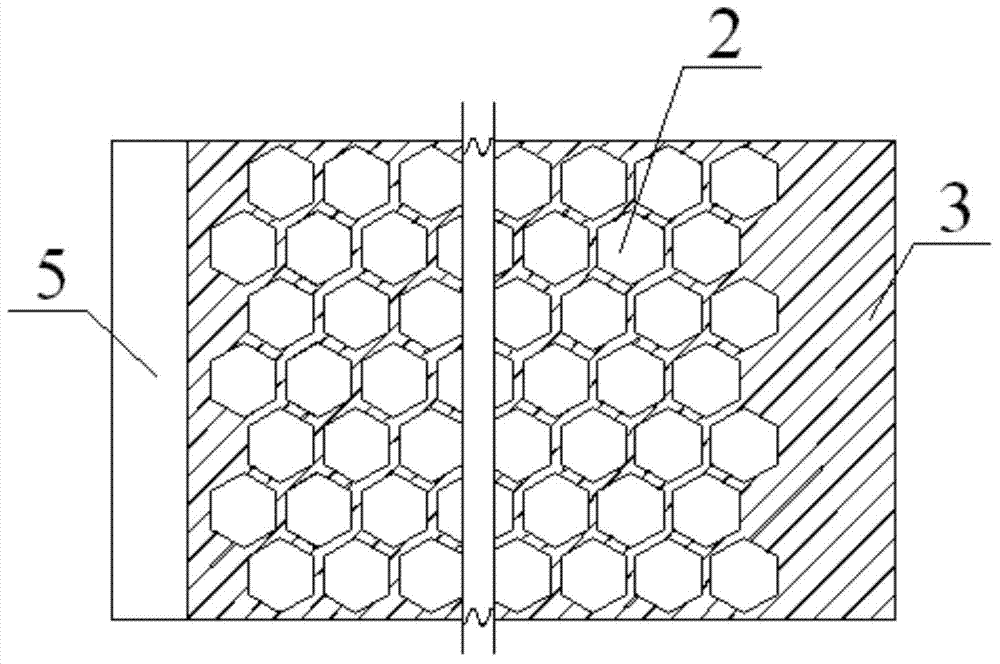

[0023] Specific implementation mode two: combination Figure 1 to Figure 8 The difference between this embodiment and the first embodiment is that the porous sandwich structure 2 is a honeycomb sandwich structure, a spatial lattice sandwich structure, a lattice sandwich structure or a corrugated plate sandwich structure. Others are the same as those in the first embodiment.

[0024] In this embodiment, the purpose of setting the porous sandwich structure 2 as a honeycomb sandwich structure, a spatial lattice sandwich structure, a grid sandwich structure or a corrugated board sandwich structure is to reduce the use of raw materials and reduce the production cost.

[0025] figure 1It is a structural schematic diagram of a melamine-based porous structure sandwich decorative panel with a honeycomb sandwich structure in the second specific embodiment, figure 1 Among them, 1 represents the decorative upper panel, 2 represents the honeycomb sandwich structure, 3 represents the prot...

specific Embodiment approach 3

[0029] Specific implementation mode three: combination Figure 1 to Figure 8 The difference between this embodiment and one of the specific embodiments 1 or 2 is: the solid volume ratio of the porous sandwich structure 2 is not less than 5%, when the solid volume ratio of the porous sandwich structure 2 is not less than 5%. %, the melamine-based porous structure sandwich decorative board is used as a wall panel, and when the solid volume of the porous sandwich structure 2 is not less than 10%, the melamine-based porous structure sandwich decorative board is used as a floor. Others are the same as those of the specific embodiment one or two.

[0030] When the melamine-based porous structure sandwich decorative panel described in this embodiment is used as a wall panel, polyurethane foam or glass glue is used for bonding, or other environmentally friendly bonding materials are selected.

[0031] The purpose of limiting the solid volume ratio of the porous sandwich structure 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Overall density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com