Heat-insulation PVC (polyvinyl chloride) plastic pipeline

A technology for plastic pipes and PVC pipes, which is used in pipe protection, pipe heating/cooling, and pipe damage/wear prevention. It can solve problems such as power waste and heat loss, and achieve the effects of good water resistance, simple structure and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

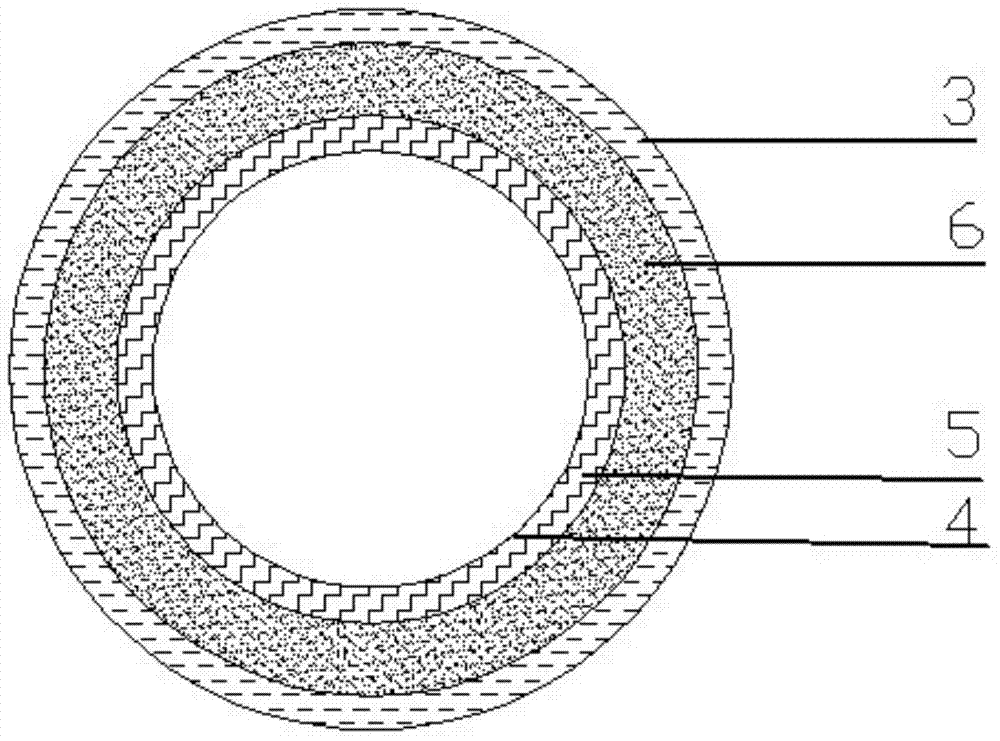

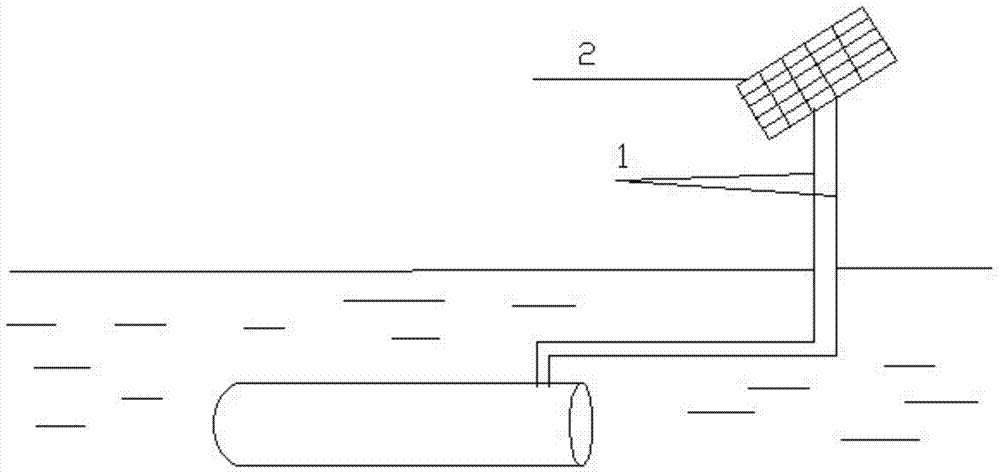

[0018] Such as figure 1 As shown, the thermal insulation PVC plastic pipe of the present invention is respectively a PVC pipe 4, a metal heat conduction layer 5, an insulation layer 6 and an anticorrosion layer 3 from inside to outside, and also includes a wire 1 connected to the joint of the metal heat conduction layer 5, so The other end of the wire 1 is connected to the solar panel 2 to form a closed loop.

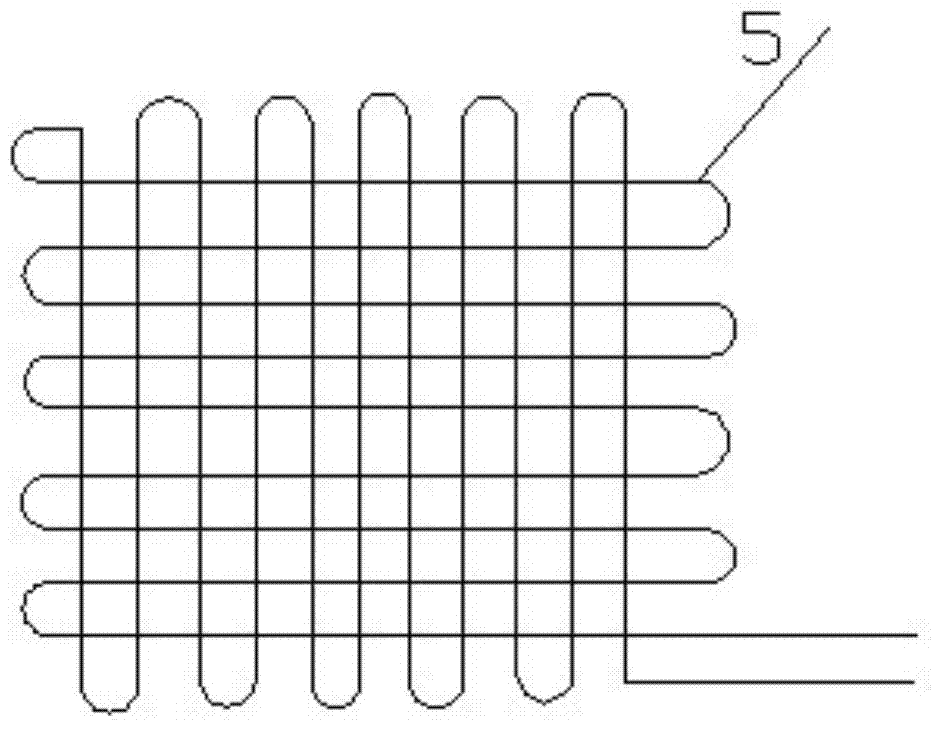

[0019] Among them, the metal heat conduction layer 5 is a mesh resistance layer with a thickness of 0.05mm-0.1mm, and the material is one of nickel-chromium alloy and iron-chromium-aluminum electrothermal alloy. After testing, the metal heat conduction layer 5 is preferably selected as The 0.05mm thick nickel-chromium alloy can ensure the most suitable temperature, not only generate enough heat, but also be unlikely to burn, and it is easy to wrap around...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com