Ultrasonic array composite imaging method for quantitative evaluation of plate structure cracks

A quantitative evaluation and ultrasonic array technology, applied in the use of ultrasonic/sonic/infrasonic waves, the use of sound waves/ultrasonic/infrasonic waves to analyze solids, measuring devices, etc., can solve problems such as the direction identification of defects that cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

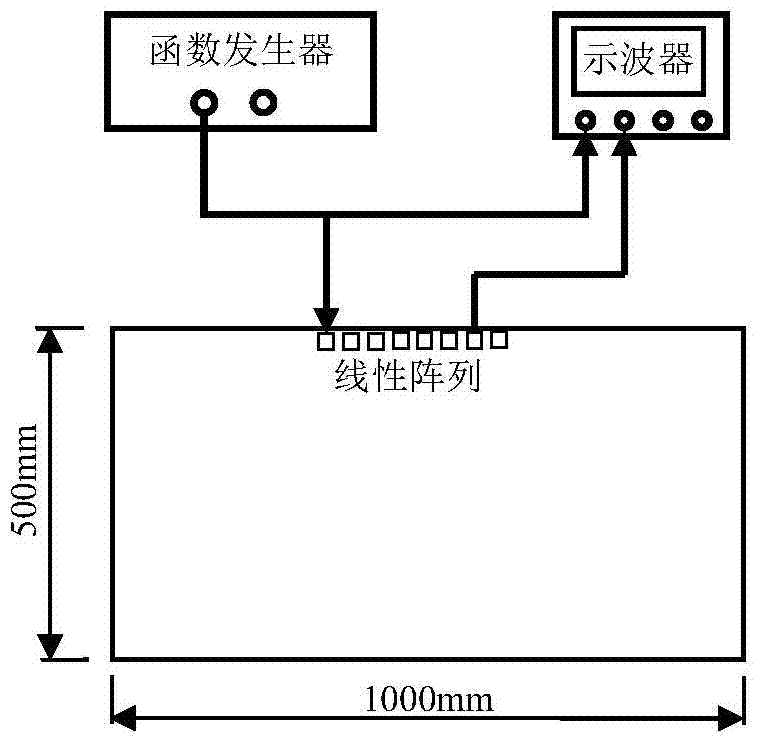

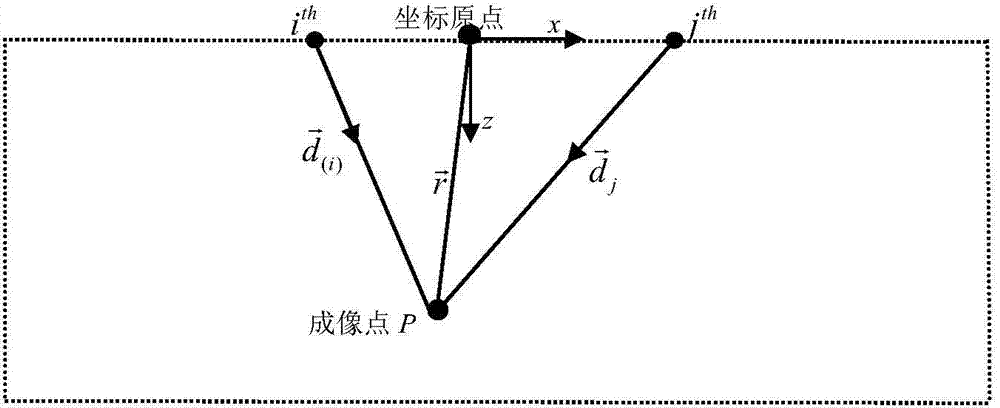

[0051] The testing instruments in this example are a function generator, an oscilloscope and a linear array transducer. The center frequency of the linear array transducer used in the experiment is f=300kHz, the total number of array elements is N=8, the width of a single array element is a=6mm, the distance between the centers of two adjacent array elements is p=2mm, and the sound wave is in the test piece The propagating wave speed c=5300m / s, then the wavelength The detection object is an aluminum plate with a length and width of 1000mm and a thickness of 1mm.

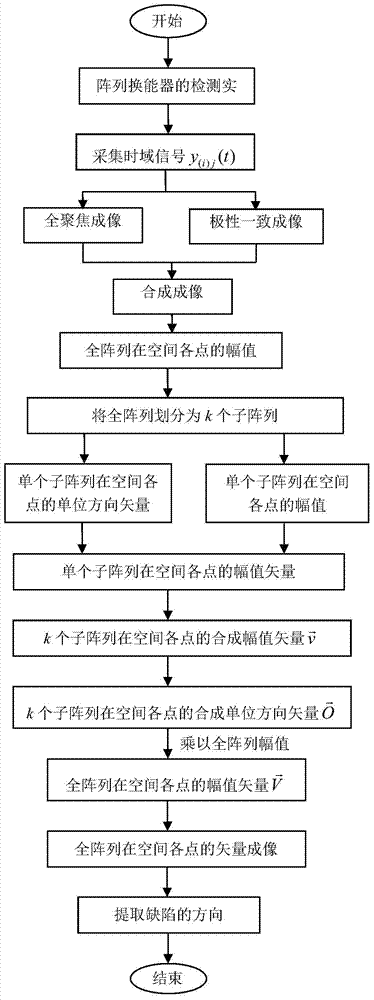

[0052] The technical solution adopted in the present invention is an ultrasonic array composite imaging method for quantitative evaluation of plate structure cracks. The specific steps are:

[0053] Step 1: In such as figure 1 The experiment is carried out under the detection dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com