Nondestructive testing method for rusting degree of steel bar of reinforced concrete member after rusting cracking

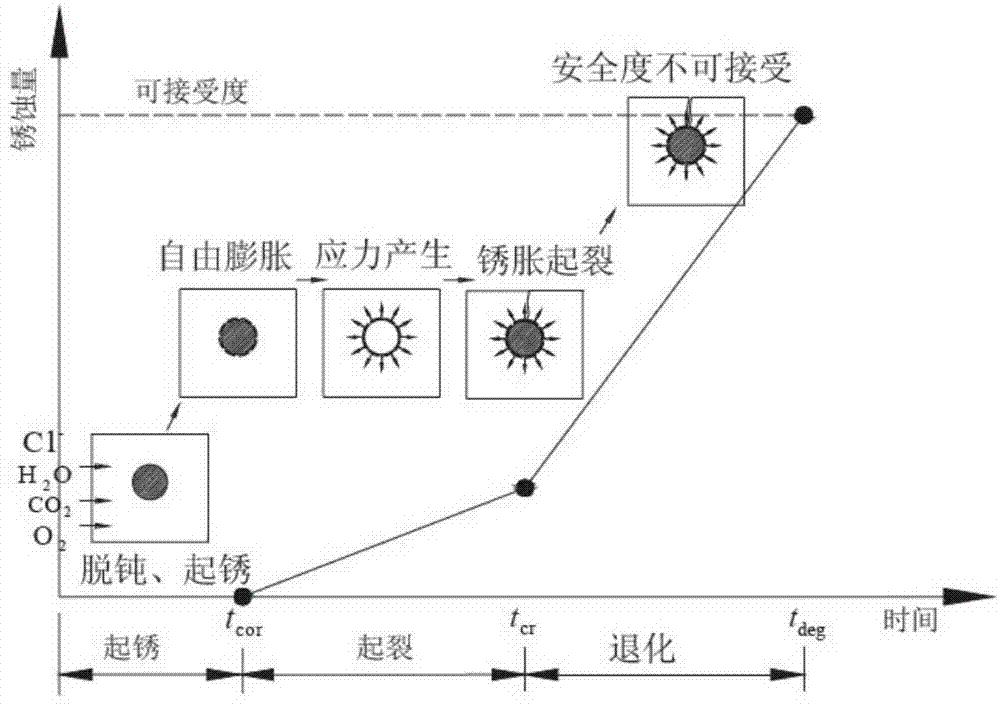

A technology for reinforced concrete and steel bar corrosion, which is applied in the field of non-destructive testing of steel bar corrosion after corrosion and cracking of reinforced concrete members, and can solve problems such as lack of mature non-destructive testing methods, reduced structural applicability, and regional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

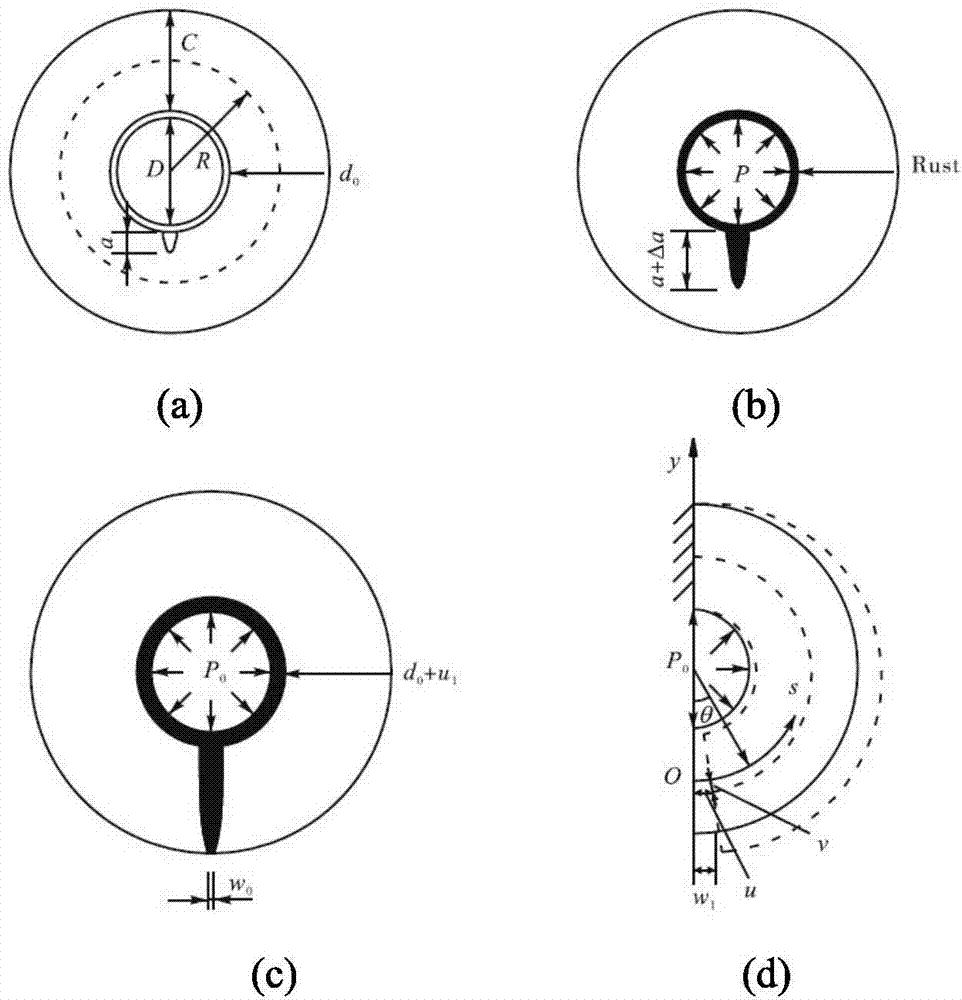

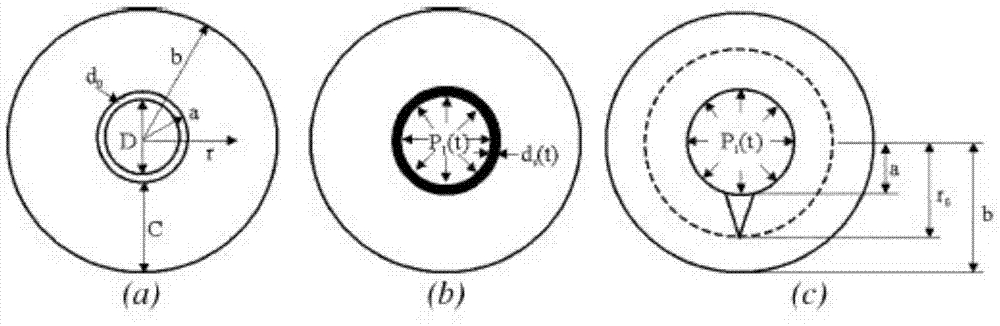

Method used

Image

Examples

example 1

[0228] Guardrail part design main reinforcement design stirrups Concrete strength rebound consists of five measurement areas, each measurement area has 16 measurement points, and the concrete carbonation depth has been detected by 2 measurement points. 3, each measuring area contains 6 measuring points, and 3 measuring points in the middle of the component are selected for the crack width. After testing, the average value of concrete strength rebound is 33.2, and the average carbonation depth is 0.46mm. According to the "Technical Regulations for Testing the Compressive Strength of Concrete by Rebound Method" (JGJ / T 23-2011), the converted concrete strength is 27.8Mpa The average thickness of the concrete cover is 28.4mm; the average crack width is 0.22mm; the length of the damaged steel bar is 26.1cm;

[0229] Utilize the calculation formula of the simplified theoretical model built by the present invention and the correction calculation formula of the rust expansion and ...

example 2

[0233] The main reinforcement at the bottom of the box girder is Φ25, the design stirrup is Φ14@180, and there are six measurement areas for concrete strength rebound, with 16 measurement points in each measurement area, and 2 measurement points for the carbonation depth of concrete. They are all arranged in the shape of "品", the number of concrete cover thickness measurement areas is 3, each measurement area contains 6 measurement points, and the crack width is selected from 3 measurement points in the middle of the component. After testing, the average value of concrete strength rebound is 44.0, and the average carbonation depth is 0.15mm. According to the "Technical Regulations for Testing the Compressive Strength of Concrete by Rebound Method" (JGJ / T 23-2011), the converted concrete strength is 50.20Mpa The average thickness of the concrete cover is 25.9mm; the average crack width is 0.17mm; the diameters of the three measuring points are 13.09mm, 13.19mm, and 13.44mm respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com