Grinding process assessment method based on reliability

A reliable and grinding technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as lack of reliability effects and lack of in-depth research on process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

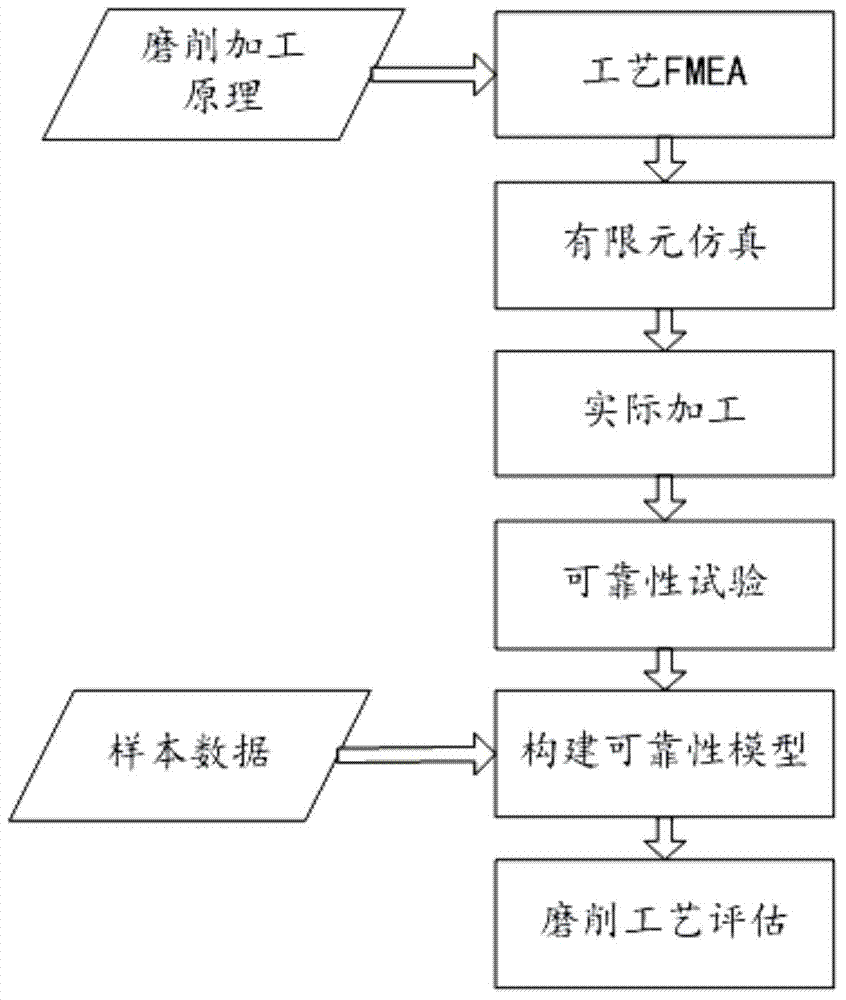

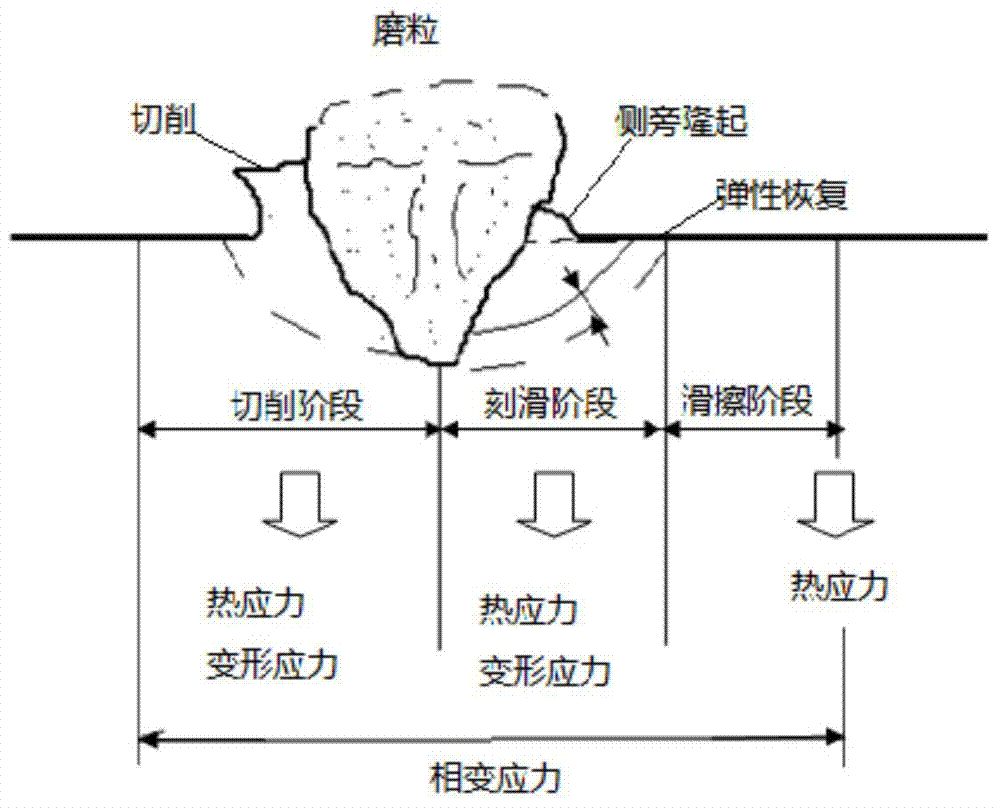

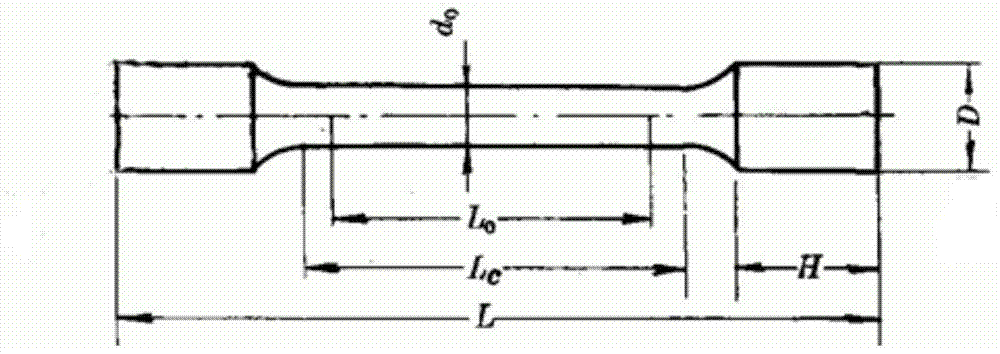

[0063] In one embodiment of the present invention, a reliability-based grinding process evaluation method is provided. Grinding and processing a batch of tensile samples, in order to obtain higher reliability, determine the best grinding process parameters. figure 2 The contact situation of abrasive grain and workpiece in the grinding process of the present invention is shown; image 3 It is the tensile sample to be processed, the two ends are rough machined, and the middle part is obtained by grinding.

[0064] Table 1 Dimensions of each part of the circular scale sample mm

[0065]

[0066] See figure 1 , a reliability-based grinding process evaluation method of the present invention, the specific steps of the method are as follows:

[0067] Step 1: According to the grinding process, the failure analysis of grinding process defects is carried out from three aspects: equipment characteristics, workpiece characteristics, and processing technology, and the grinding proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com