Acoustic shielding screen for absorbing sound by using coplanar hollow tube

A hollow tube and sound-absorbing screen technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of adding extra weight, sound-absorbing materials occupy a large space, etc., and achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

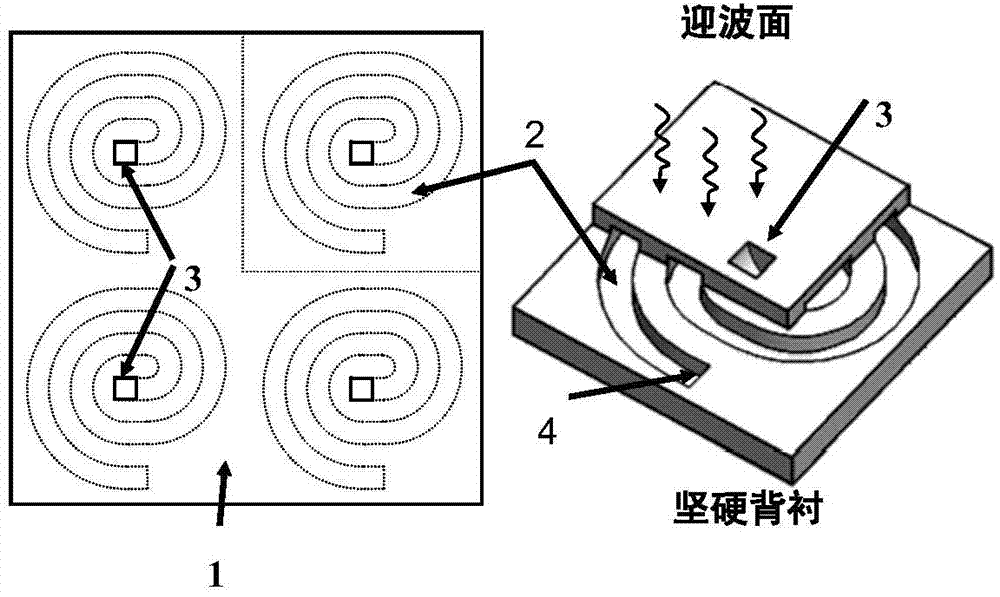

[0033] figure 1 It is an implementation of the present invention, wherein the sound-absorbing screen 1 includes a coplanar hollow tube 2 formed by an opening 3 , a spiral groove 2 and a closed end 4 .

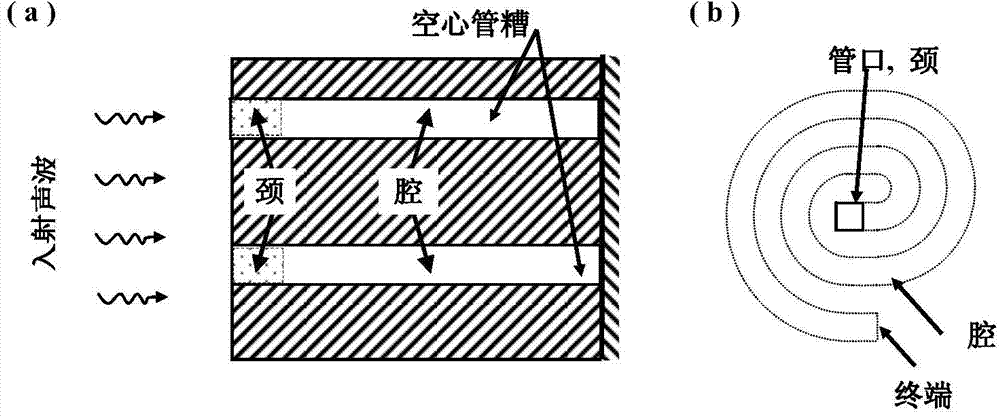

[0034] figure 2 The equivalent relationship between the coplanar hollow tube structure and the Helmholtz resonant cavity in the present invention is shown. When the sound wave is incident into the straight hollow tube, the opening of the straight hollow tube is equivalent to the neck of the Helmholtz resonator, and the deep part inside is equivalent to the cavity of the Helmholtz resonator ( figure 2 a). Coiled (coplanar) hollow tubes ( figure 2 b) with straight hollow tube ( figure 2 a) have the same working mechanism.

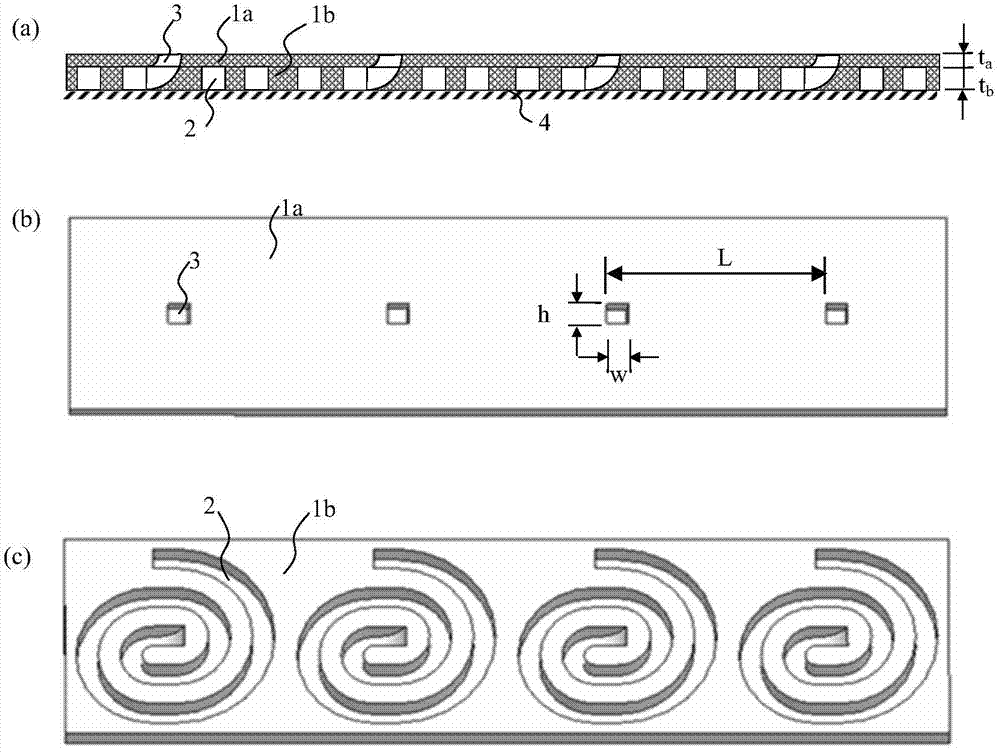

[0035] image 3 The internal structure of the coplanar hollow tube sound-absorbing screen of the present invention is shown. The through hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com