Resonator Element, Electronic Device, Electronic Apparatus, And Moving Object

A technology of vibrating element and vibrating arm, applied in the fields of vibrating element, electronic device, electronic equipment and moving body, can solve the problems of Q value reduction, leakage, error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

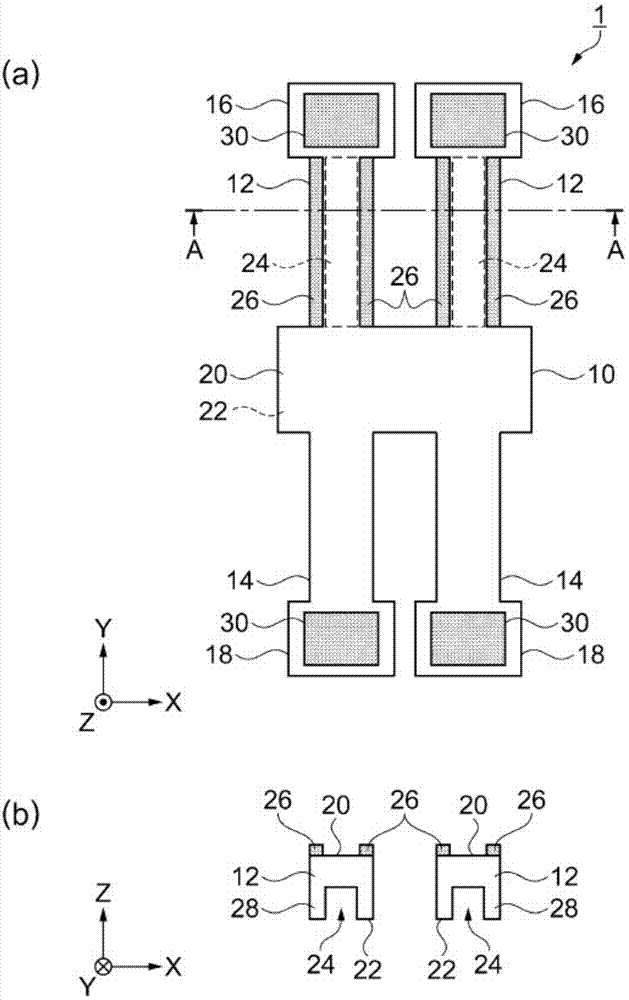

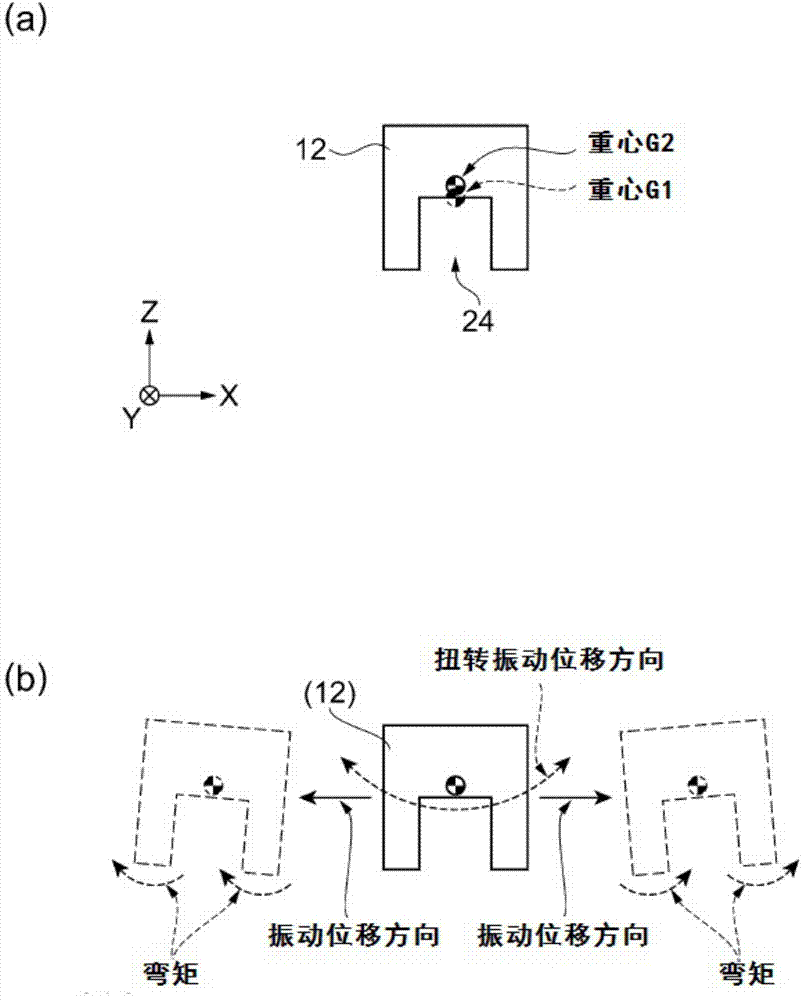

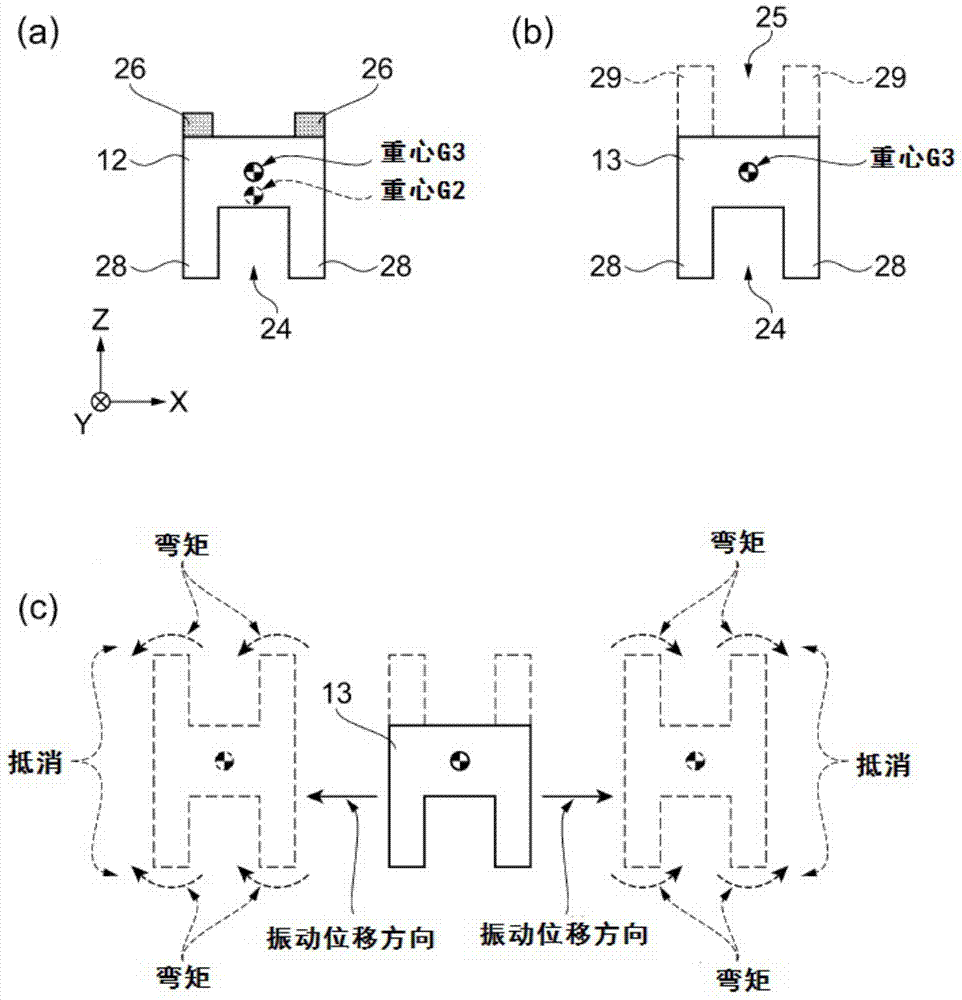

[0056] As an example of the vibrating element according to the first embodiment of the present invention, a vibrating element with a structure called an H type used in an angular velocity sensor is given, and refer to figure 1 Be explained.

[0057] figure 1 It is a schematic diagram showing the configuration of the vibrating element 1 according to the first embodiment of the present invention. figure 1 (a) is a top view, figure 1 (b) for figure 1 (a) A cross-sectional view along line A-A. Also, electrodes for driving and electrodes for detection are omitted. In addition, in each figure, for convenience of description, the X-axis, the Y-axis, and the Z-axis are illustrated as three mutually orthogonal axes, and the tip side of the arrow mark in the illustration is referred to as the "+ side", Set the base end side to "- side". In addition, below, the direction parallel to the X-axis is called "X-axis direction", the direction parallel to the Y-axis is called "Y-axis dire...

no. 2 approach

[0087] Next, refer to Figure 7 as well as Figure 8 , the vibration element 1d according to the second embodiment of the present invention will be described.

[0088] Figure 7 It is a schematic diagram showing the structure of a vibrating element 1d according to the second embodiment of the present invention. Figure 7 (a) is a top view, Figure 7 (b) for Figure 7 (a) E-E line sectional view. Figure 8 It is a schematic diagram explaining the vibration state of the vibration element 1d according to the second embodiment of the present invention. Figure 8 (a) is a sectional view of the vibrating arm 12, Figure 8 (b) is a sectional view of the imaginary vibrating arm 15, Figure 8 (c) is a sectional view of the virtual vibrating arm 15 showing a vibrating state.

[0089] Hereinafter, the resonator element 1d of the second embodiment will be described centering on the points of difference from the resonator element 1 of the first embodiment described above, and the s...

no. 3 approach

[0094] Next, according to Figure 9 , the vibration element 1e according to the third embodiment of the present invention will be described.

[0095] Figure 9 It is a schematic diagram showing the structure of the vibrating element 1e according to the third embodiment of the present invention. Figure 9 (a) is a top view, Figure 9 (b) for Figure 9 The sectional view of F1-F1 line shown in (a), Figure 9 (c) for Figure 9 (a) F2-F2 line sectional view shown.

[0096] Hereinafter, the resonator element 1e of the third embodiment will be described focusing on the points of difference from the resonator element 1 of the first embodiment described above, and the same reference numerals will be assigned to the same items, and descriptions thereof will be omitted. .

[0097] Such as Figure 9 (a) to Figure 9As shown in (c), the outer shape of the vibrating element 1e of the third embodiment in which the groove portion 24 is provided on the vibrating arm 12 is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com