Small hydraulic bionic type cassava harvesting machine

A bionic, harvester technology, applied in excavating harvesters, harvesters, excavators, etc., can solve the problems of high soil viscosity, difficult harvesting, poor adaptability, etc. Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

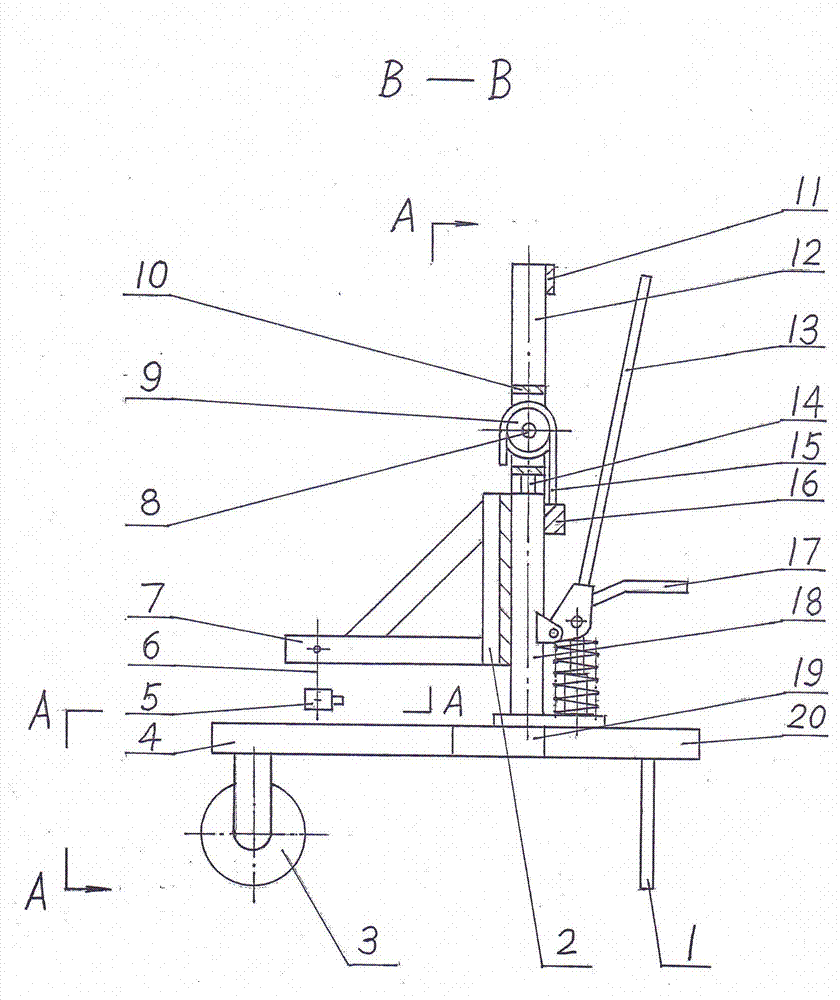

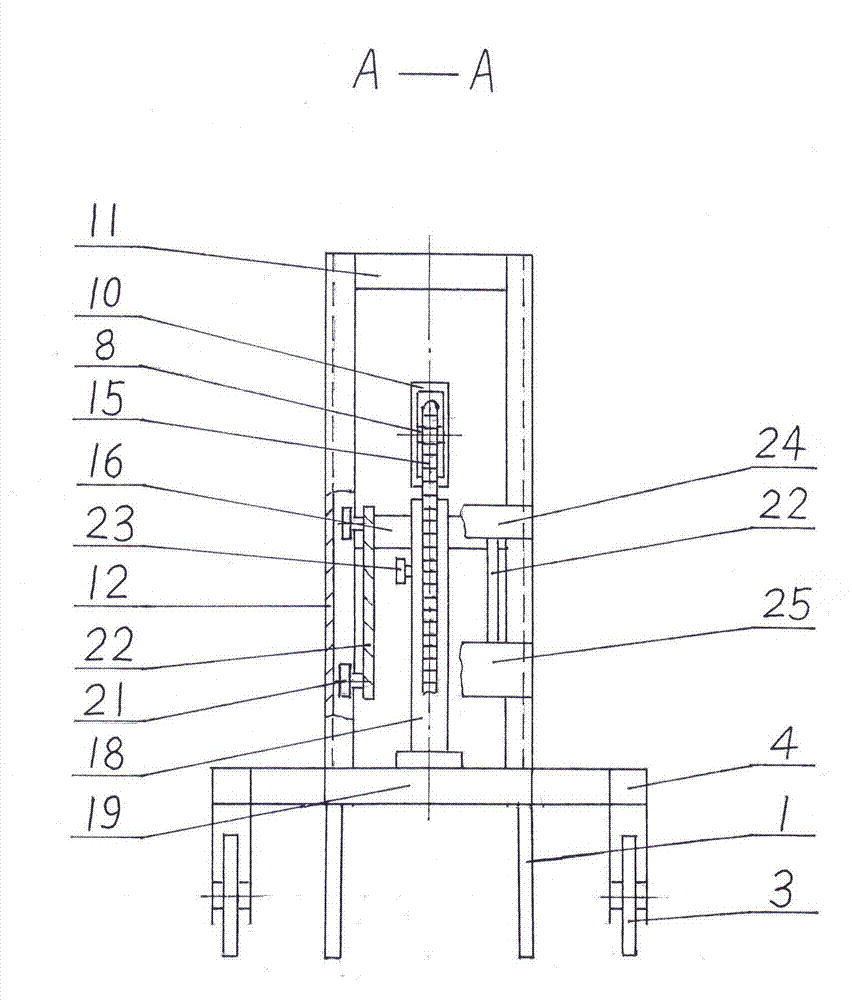

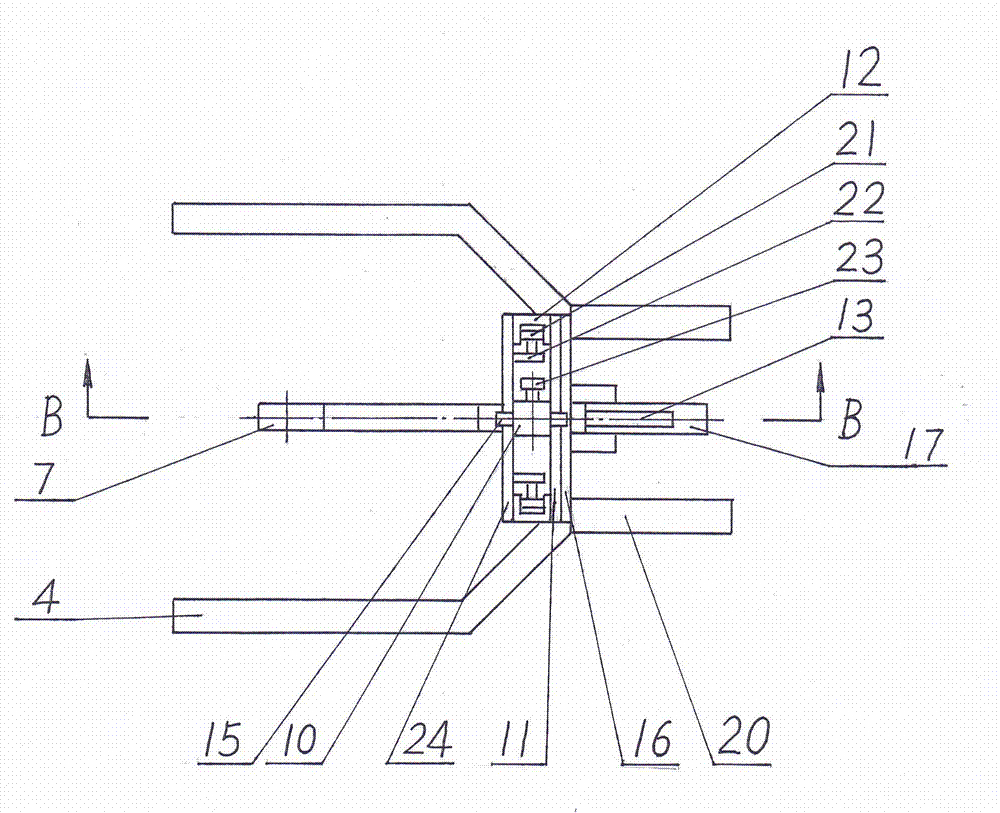

[0012] Press down the lifting rod [13] or the lifting pedal [17], the lifting plunger rod [14] on the hydraulic jack [18] drives the sprocket [9] to move upward, thereby driving the chain [15] to move upward, and the chain [15] drives the sliding frame [2] to move upwards, thereby driving the pulling arm [7] on the sliding frame [2] to move upwards, and the pulling arm [7] drives the flexible member [6] and the cassava stem clamp [5] ] move up to pull up the cassava; open the oil return valve [23], the lifting plunger rod [14] can be lowered, thereby driving the sprocket [9], the chain [15], the carriage [2] and the Lifting arm [ 7 ] and cassava stalk clamp [ 5 ] on the frame [ 2 ] descend.

[0013] A pair of bicycle legs [1] and a pair of wheels [3] are used for supporting and walking, adopting this structure can walk on narrow, rugged mountain roads, and work on fields with many ditches and ridges and uneven ground.

[0014] The flexible member [6] can also be connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com