Application of O-(1H-tetrazole) ethyl derivative of cleistanone to preparing drug for preventing or treating pancreatic fibrosis

A technology of ethyl derivatives and pancreatic fibrosis, which is applied in drug combinations, medical preparations containing active ingredients, digestive system, etc., can solve the problems of low safety and high toxicity, and achieve good anti-pancreatic fibrosis effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

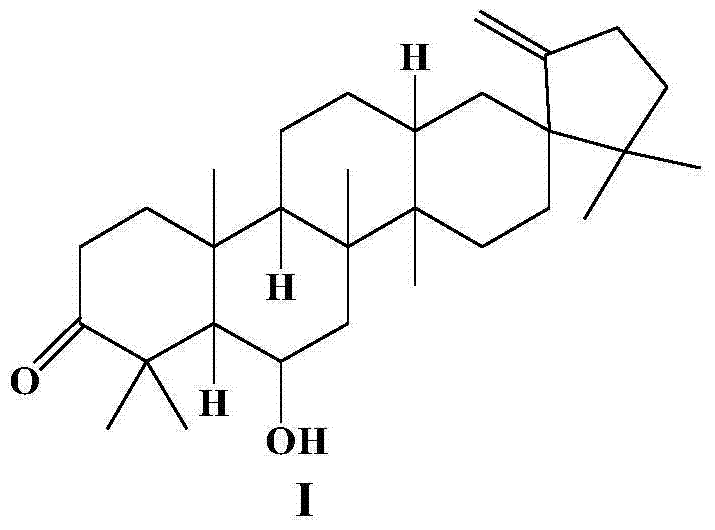

[0017] Preparation of Example 1 Compound Cleistanone

[0018] The preparation method of the compound Cleistanone (I) refers to the literature published by Van Trinh Thi Thanh et al. , pages 4108–4111, August 2011).

[0019]

Embodiment 2

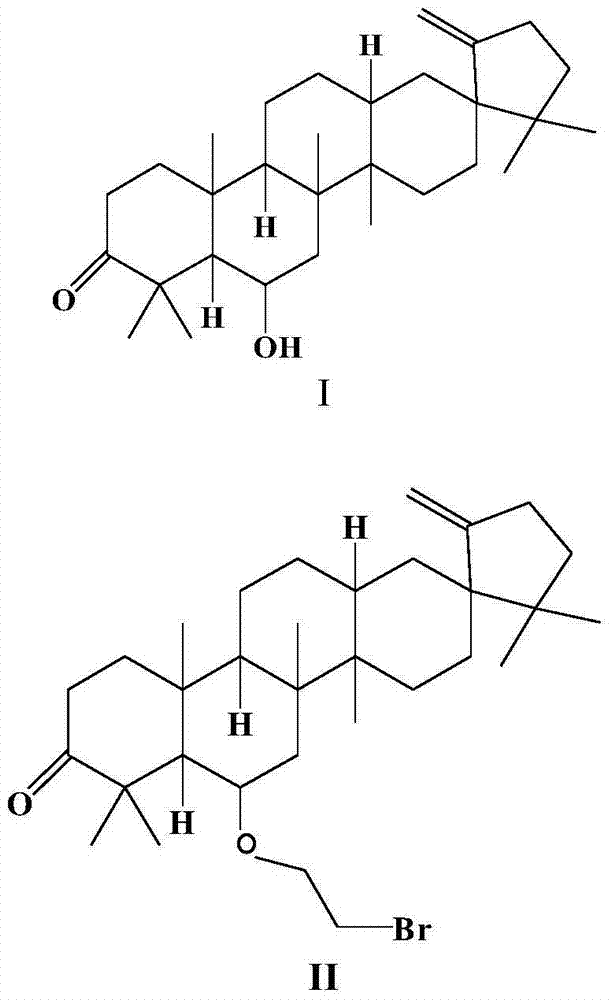

[0020] Synthesis of O-bromoethyl derivatives (II) of cleistanone Cleistanone of embodiment 2

[0021] Compound I (440 mg, 1.00 mmol) was dissolved in 10 mL of benzene, and tetrabutylammonium bromide (TBAB) (0.04 g), 1,2-dibromoethane (3.760 g, 20.00 mmol) and 6 mL of 50% sodium hydroxide solution. The mixture was stirred at 25 °C for 24 h. After 24 hours, the reaction solution was poured into ice water, extracted twice with dichloromethane immediately, and the organic phase solutions were combined. Then the organic phase solution was washed with water and saturated brine three times successively, then dried with anhydrous sodium sulfate, and finally concentrated under reduced pressure to remove the solvent to obtain a crude product. The crude product was purified by silica gel column chromatography (mobile phase: petroleum ether / acetone=100:1, v / v), and the yellow concentrated elution band was collected to obtain compound II as a yellow solid (344 mg, 63%).

[0022] 1H NMR ...

Embodiment 3

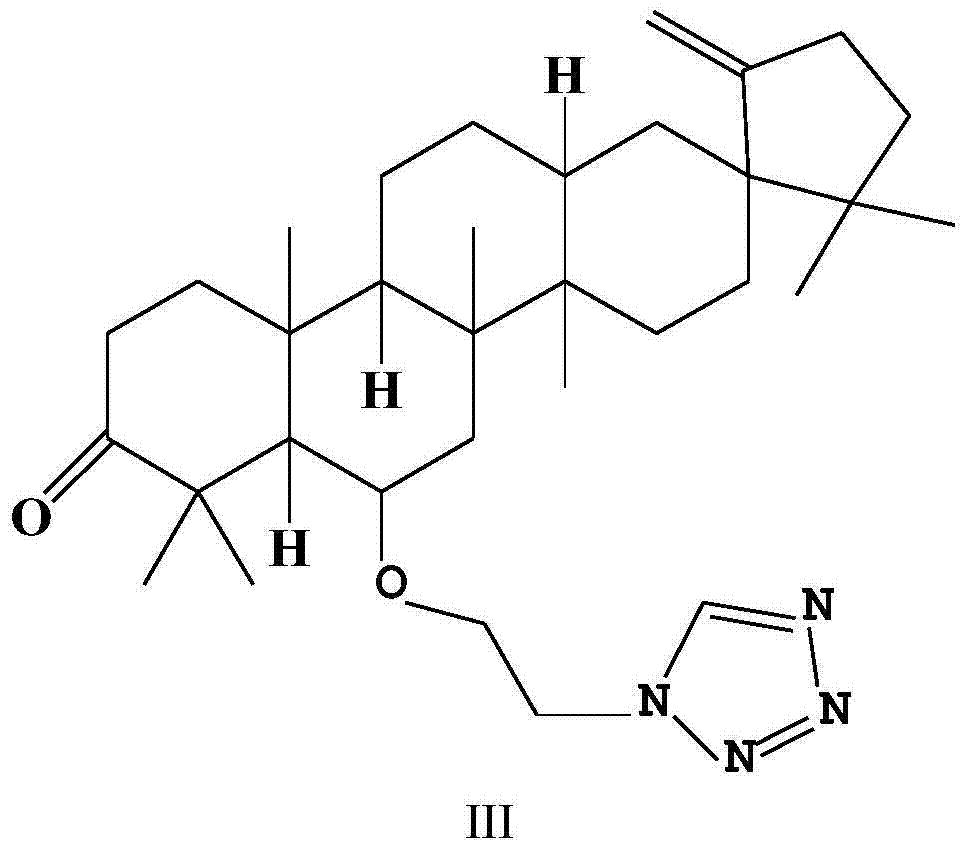

[0026] Example 3 Synthesis of O-(1H-tetrazolyl)ethyl derivatives (III) of Cleistanone

[0027] Compound II (273mg, 0.5mmol) was dissolved in 15mL of acetonitrile, anhydrous potassium carbonate (345mg, 2.5mmol), potassium iodide (84mg, 0.5mmol) and 1H-tetrazolium (1401mg, 20mmol) were added thereto, and the mixture was heated Reflux 10h. After the reaction was completed, the reaction solution was poured into ice water, extracted three times with an equal amount of dichloromethane, and the organic phases were combined. The combined organic phases were successively washed with water and saturated brine, dried over anhydrous sodium sulfate, and concentrated under reduced pressure to remove the solvent to obtain a crude product. Because of tautomerism, two substitution products, 1H-tetrazolyl and 2H-tetrazolyl, will be generated under the reaction conditions. The crude product was purified by silica gel column chromatography (mobile phase: petroleum ether / acetone=100:1, v / v), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com