Multi-system rail vehicle fireless returning device

A rail vehicle, fireless return technology, applied in vehicle parts, brake transmission, transportation and packaging, etc., can solve the problems of the normal operation of the road, the inability to use rail vehicles, the backwardness of the fireless return device, etc., to achieve a variety of The effect of stability, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

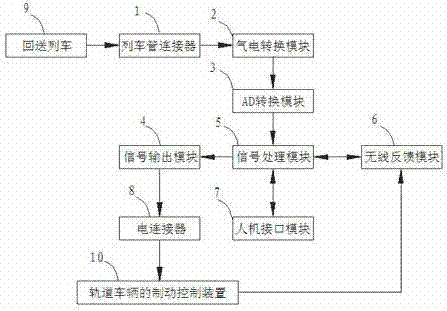

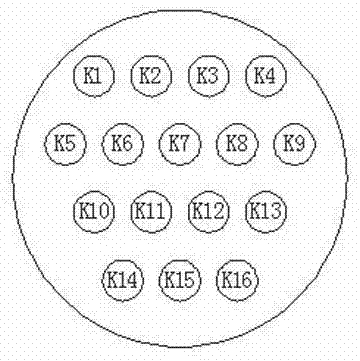

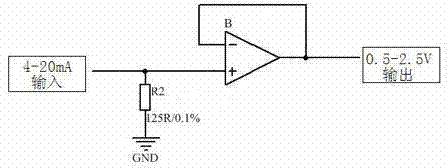

[0012] In the view, the main body includes a train tube connector 1, a gas-to-electric conversion module 2, an AD conversion module 3, a signal output module 4, a signal processing module 5, a wireless feedback module 6, a man-machine interface module 7 and an electrical connector 8, the train The pipe connector 1 is used to connect the external return train 9 to collect the train air pressure, and the electrical connector 8 is used to connect the brake control device 10 of the returned rail vehicle to transmit the braking command; the gas-electric conversion module 2 and the train pipe The connector 1 and the AD conversion module 3 are connected respectively, and are used to convert the air pressure signal collected from the train pipe connector 1 into a current signal of 4-20mA, and then send it to the AD conversion module 3 for processing; the AD conversion module 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com