An industrial sewage recycling system

A technology for industrial sewage and new water, applied in water/sludge/sewage treatment, descaling and water softening, special treatment goals, etc., can solve environmental protection requirements and uncoordinated sustainable concepts, large sewage discharge, and restrict coking Improve the economic benefits of the plant and improve market competitiveness, etc., to achieve the effect of zero discharge of sewage, zero discharge, and consumption supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

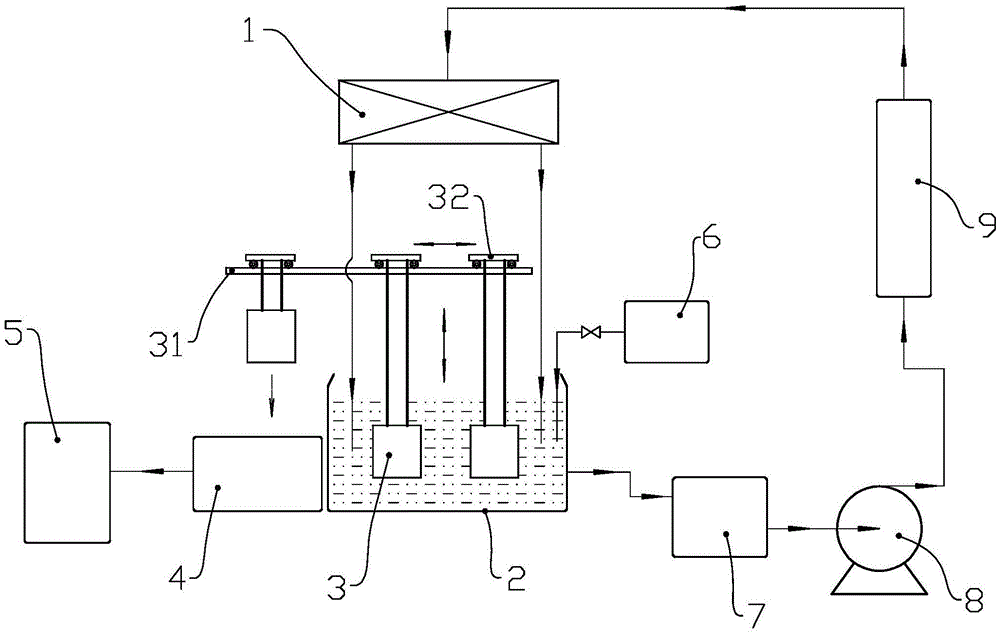

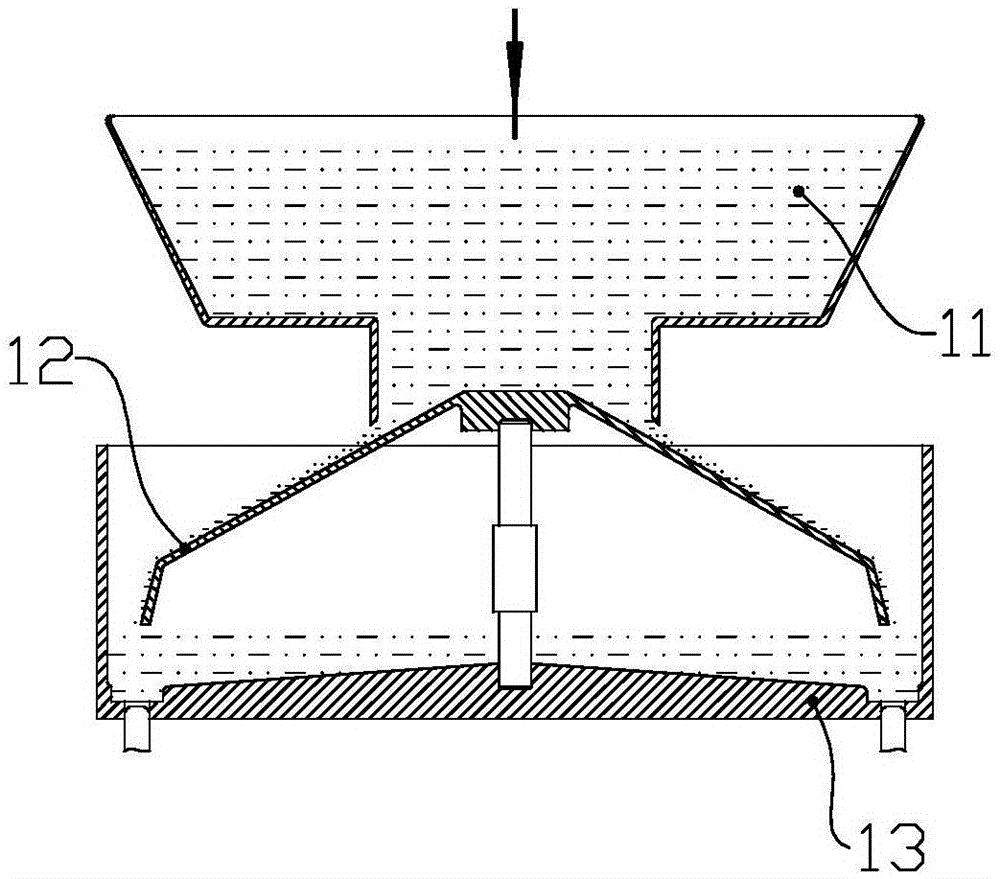

[0016] Such as figure 1 As shown, an industrial sewage recovery and recycling system includes a cold water pool 1, a water collection pool 2, a dirt collector 3, a driving rail frame 31, a driving car 32, a transfer car 4, a sintering equipment 5, a fresh water replenishment pool, and a circulating water pool 7 , circulating water pump 8 and water unit 9. The cool water pool 1 is arranged above the sump 2 , and the water outlet at the lower end of the cool water pool 1 is connected to the sump 2 . The driving rail frame 31 is extended left and right in the horizontal plane and extends to the left by a certain length directly above the sump 2 , and the transfer vehicle 4 is arranged directly below the extended part. The track of the transfer car 4 extends to the batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com