Natural gas compressor with dehumidification function

A natural gas and compressor technology, applied in the field of natural gas compressors, can solve the problems of easy ice blockage, labor and time-consuming, affecting the normal operation of equipment, etc., and achieve the effect of high accuracy and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

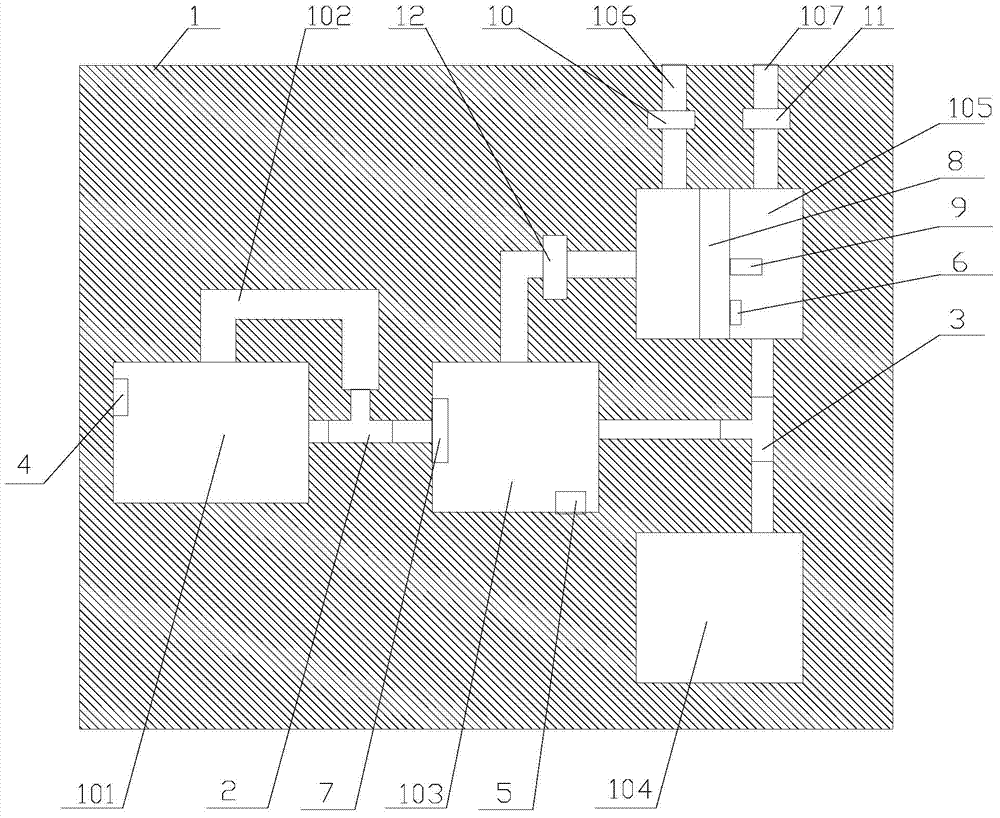

[0022] refer to figure 1 , a natural gas compressor with dehumidification function proposed by the present invention, comprising: a body 1, a first three-way valve 2, a second three-way valve 3, a pressure sensor 4, a first humidity sensor 5, a second humidity sensor 6 and control module. The main body 1 is provided with a compression chamber 101 , a return passage 102 , an exhaust chamber 103 , an air storage chamber 104 , a drying chamber 105 , an air suction passage 106 and an exhaust passage 107 .

[0023] A compression device is provided inside the compression chamber 101 for compressing gas. In this embodiment, the compression device is a piston, the inlet and outlet of the compression chamber 101 and the return channel 102 are located on the same side of the piston, and the piston compresses the gas through reciprocating motion. In practice, the compression device may also use a turbine, and the inlet of the compression chamber 101 and the return channel 102 are locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com