High reliability and long life gas dynamic pressure bearing

A gas dynamic pressure bearing and reliability technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of complex hemispherical structure, reduce reliability, weaken dry friction, etc., and achieve high angular compliance and easy to solve. The effect of processing and reducing magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

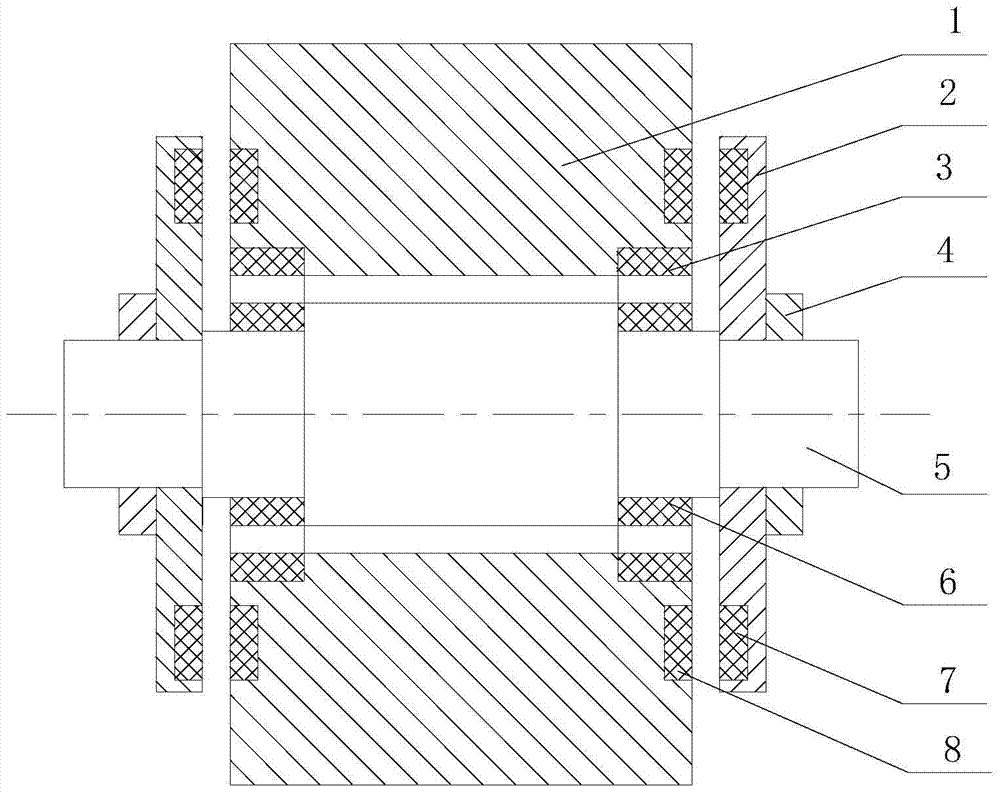

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0020] A high-reliability and long-life gas dynamic pressure bearing, including a shaft sleeve 1, a thrust plate 2, a shaft 5 and a nut 4, the shafts are coaxially inserted into the shaft hole of the shaft sleeve, and a stopper is installed at the left and right ends of the shaft. push plate. The shaft sleeve, thrust plate, nut and shaft are made of the same material, such as A1, Cr18Ni9Ti, 1Cr18Ni, 40Cr, and adopt a symmetrical structure, which can ensure the stability of the center of mass when the ambient temperature changes.

[0021] The innovation of the present invention is that: the left and right ends of the bushing are embedded and bonded with a magnetic ring 8 on the end face of the bushing to form a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com