Method for detecting shearing strength of interlayer bonding surface of rock filled concrete of constructional engineering

A technology of rockfill concrete and interlayer bonding, which is applied in the direction of applying stable shear force to test the strength of materials, etc. The test process is simple, easy to move, and the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

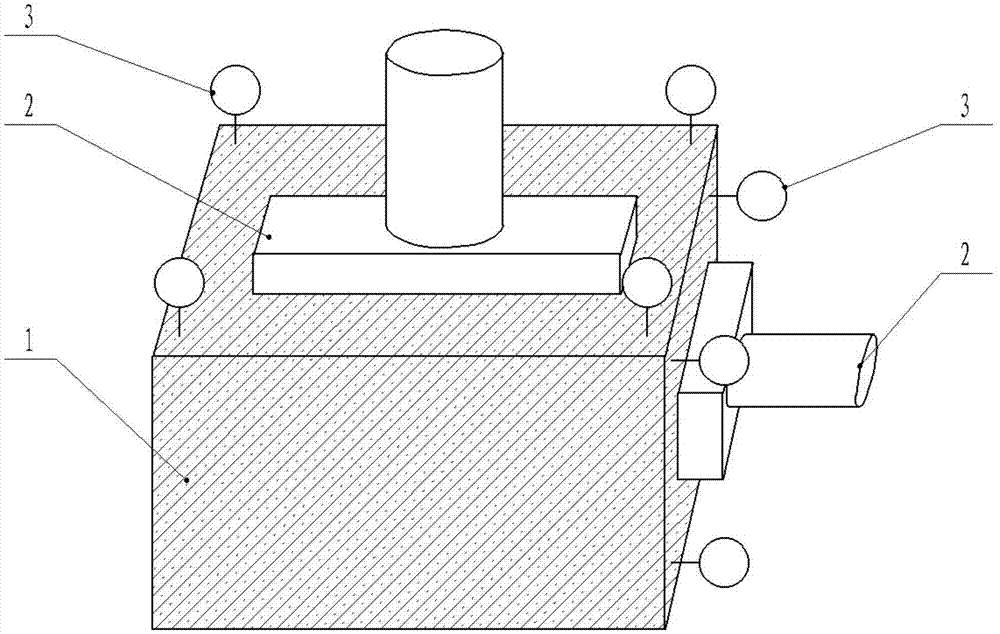

Embodiment 1

[0030] A method for detecting the shear strength of the joint surface between layers of rock-fill concrete in construction engineering. Five test pieces are made on the rock-fill concrete dam or rock-fill concrete foundation to be tested. The test pieces are 1000mm long, 1000mm wide and 1000mm high 1000mm rock-fill concrete test piece, the test piece includes the interlayer bonding site of the rock-fill concrete dam. Four dial gauges are installed symmetrically in the horizontal and vertical directions of each test piece to detect the horizontal deformation and vertical deformation of the test piece respectively. Jacks are respectively installed on the horizontal plane and the vertical plane of the test specimen to apply the load in the horizontal direction and the load in the vertical direction. The vertical load is applied step by step, and the loading is controlled by time, and the loading is performed every 3 minutes. After loading, the reading is taken immediately, and th...

Embodiment 2

[0037] A method for detecting the shear strength of the joint surface between layers of rock-fill concrete in construction engineering. Six test pieces are made on the rock-fill concrete dam or rock-fill concrete foundation to be tested. The test pieces are 1200mm long, 1200mm wide, and 1200mm rock-fill concrete test piece, the test piece includes the interlayer bonding site of the rock-fill concrete dam. Four dial gauges are installed symmetrically in the horizontal and vertical directions of each test piece to detect the horizontal deformation and vertical deformation of the test piece respectively. Jacks are respectively installed on the horizontal plane and the vertical plane of the test specimen to apply the load in the horizontal direction and the load in the vertical direction. The vertical load is applied step by step, and the loading is controlled by time, every 5 minutes, and the reading is taken immediately after loading, and the next level of load can be applied. ...

Embodiment 3

[0043]A method for detecting the shear strength of the interlayer bonded surface of rock-fill concrete in construction engineering. Eight test pieces are made on the rock-fill concrete dam or rock-fill concrete foundation to be tested. The test pieces are 1300mm long, 1300mm wide, and 1300mm rock-fill concrete test piece, the test piece includes the interlayer bonding site of the rock-fill concrete dam. Four dial gauges are installed symmetrically in the horizontal and vertical directions of each test piece to detect the horizontal deformation and vertical deformation of the test piece respectively. Jacks are respectively installed on the horizontal plane and the vertical plane of the test specimen to apply the load in the horizontal direction and the load in the vertical direction. The vertical load is applied step by step, and the loading is controlled by time, and the loading is performed every 10 minutes. After loading, the reading is taken immediately, and the next level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com