A method and system for monitoring the stability of a lithography machine

A lithography machine and stable technology, applied in the direction of micro-lithography exposure equipment, photolithography process exposure device, etc., can solve the problems of waste of resources, high cost of lithography machine monitoring and operation, save money, reduce monitoring and operation costs, The effect of improving the efficiency of data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

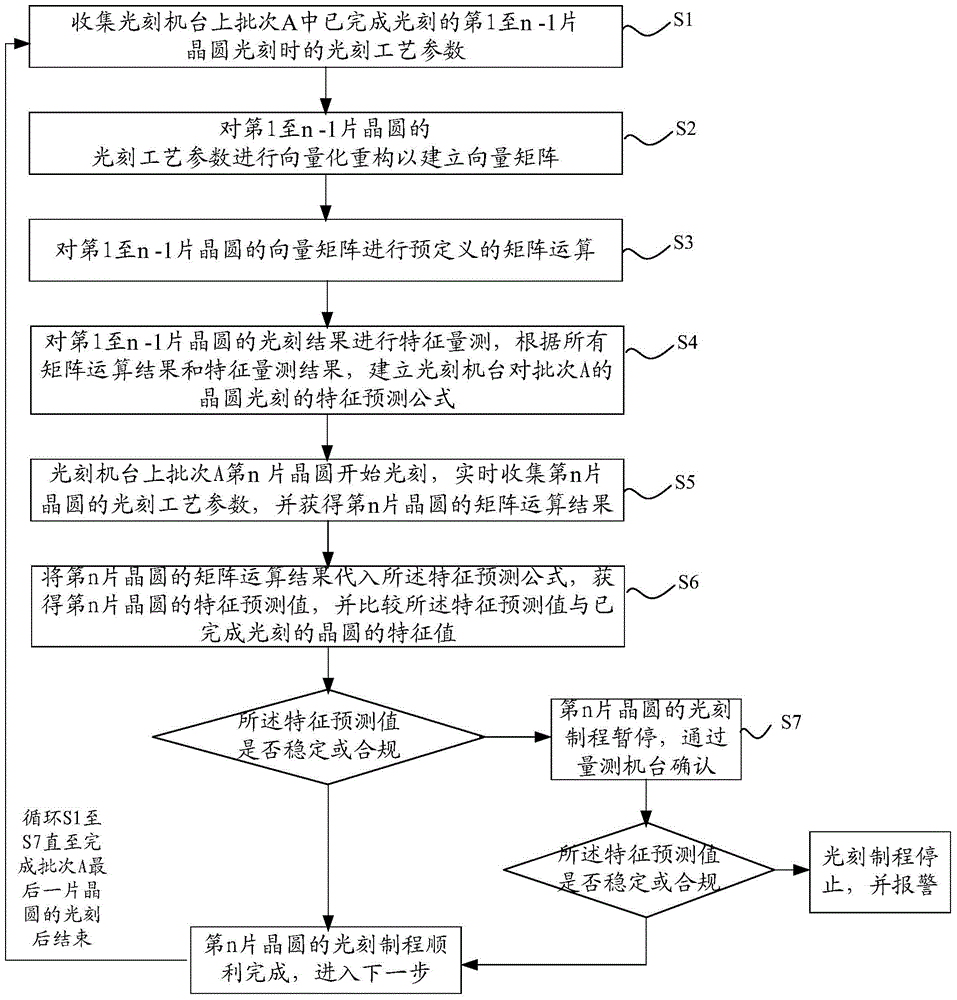

[0036] Please refer to figure 1 , this embodiment provides a method for monitoring the stability of a lithography machine, including steps S1 to S7, specifically as follows:

[0037] Step S1, collect the photolithography process parameters of the multi-wafers that have been photoetched in the same batch on the photolithography machine. In this embodiment, the 1st to nth wafers that have been photoetched in batch A are collected. -1 (n is greater than 1) lithography process parameters of the wafer in the lithography process of the lithography machine, such as focus value, energy dose, illumination mode and other light source property parameters and horizontal alignment accuracy X, vertical alignment Alignment parameters such as precision Y, stage level height, etc.

[0038] Step S2, perform vectorized reconstruction on the photolithography process parameters to establish a vector matrix, specifically, first, the data collected in step S1 (such as focus value, energy dose, illu...

Embodiment 2

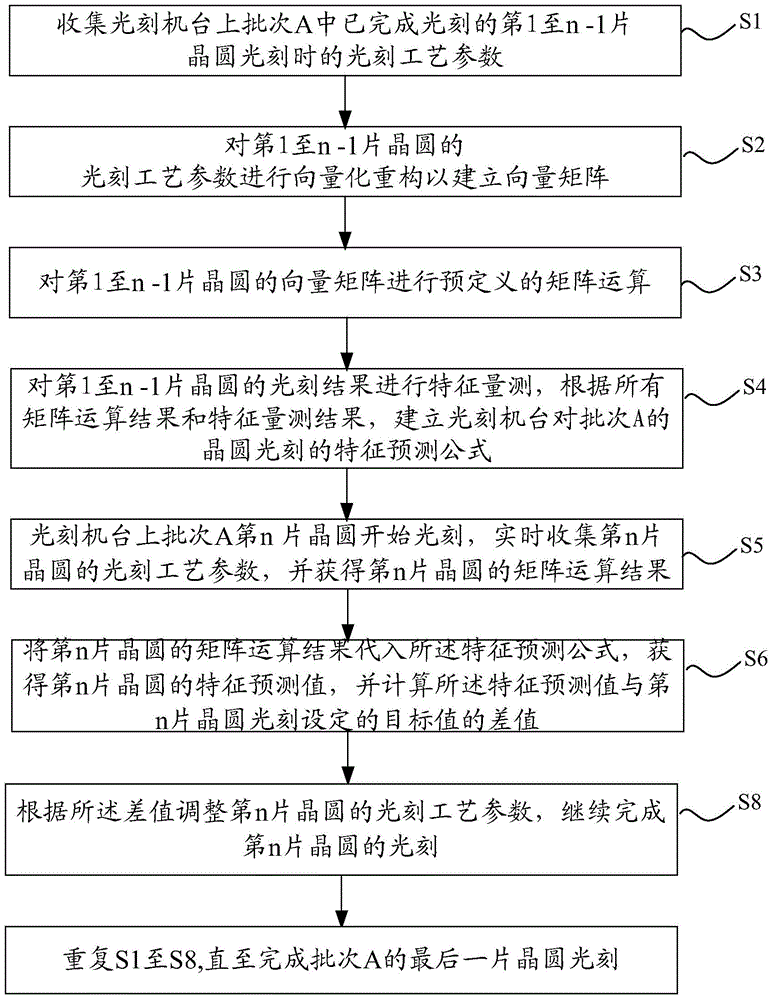

[0053] Please refer to figure 2 , this embodiment provides a method for monitoring the stability of a lithography machine, including steps S1 to S8, specifically as follows:

[0054] Step S1, collecting the lithography process parameters during the lithography of multiple wafers that have been lithography completed in the same batch on the lithography machine;

[0055] Step S2, performing vectorized reconstruction on the photolithography process parameters to establish a vector matrix;

[0056] Step S3, performing a predefined matrix operation on the vector matrix;

[0057] Step S4, perform feature measurement on the lithography results of each wafer that has been lithography completed, and establish a lithography machine to perform photolithography on the same batch of wafers according to the matrix operation results and the feature measurement results. Engraved feature prediction formula;

[0058] Step S5, collecting in real time the lithography process parameters of the...

Embodiment 3

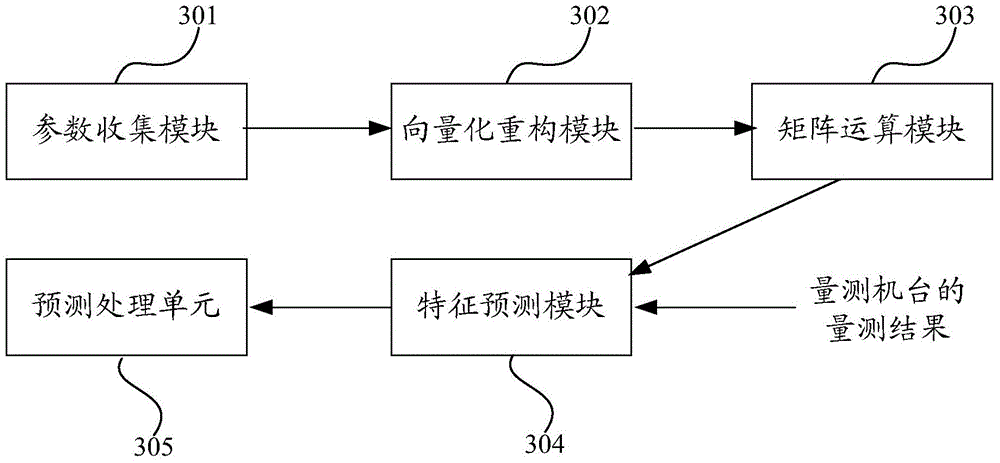

[0065] Please refer to image 3 , this embodiment provides a system for monitoring the stability of a lithography machine, including:

[0066] The parameter collection module 301 is used to collect the lithography process parameters of the lithography machine for the photolithography of multiple wafers that have been lithography completed in the same batch, and collect the lithography process parameters of the lithography machine in the same batch in real time. The photolithography process parameters of the wafer;

[0067] The vectorized reconstruction module 302 is used to perform vectorized reconstruction on the lithography process parameters of the multi-chip wafers that have been lithography collected by the parameter collection module 301 and the lithography process parameters of the wafer being lithography to establish a vector matrix;

[0068] A matrix operation module 303, configured to perform a predefined matrix operation on the vector matrix established by the vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com