Driving control circuit used for laser tracker precision servo system

A technology for driving control circuits and laser trackers, applied in the field of laser trackers, can solve problems such as low reliability of collected data, poor low-speed control performance, and low control frequency, so as to reduce the amount of calculation, increase control frequency, and high operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Compared with the previous hardware circuit of the control system, the present invention adds FPGA chips and large-capacity SRAM chips with high cost performance, greatly improves the operating efficiency of the control algorithm, and the real-time performance of data collection. , and adopt the form of multi-board combination, which greatly increases the functionality and flexibility of the drive control circuit. In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0029] In one embodiment of the present invention, a drive control circuit for a precision servo system of a laser tracker is provided for driving and controlling a high-performance permanent magnet synchronous motor.

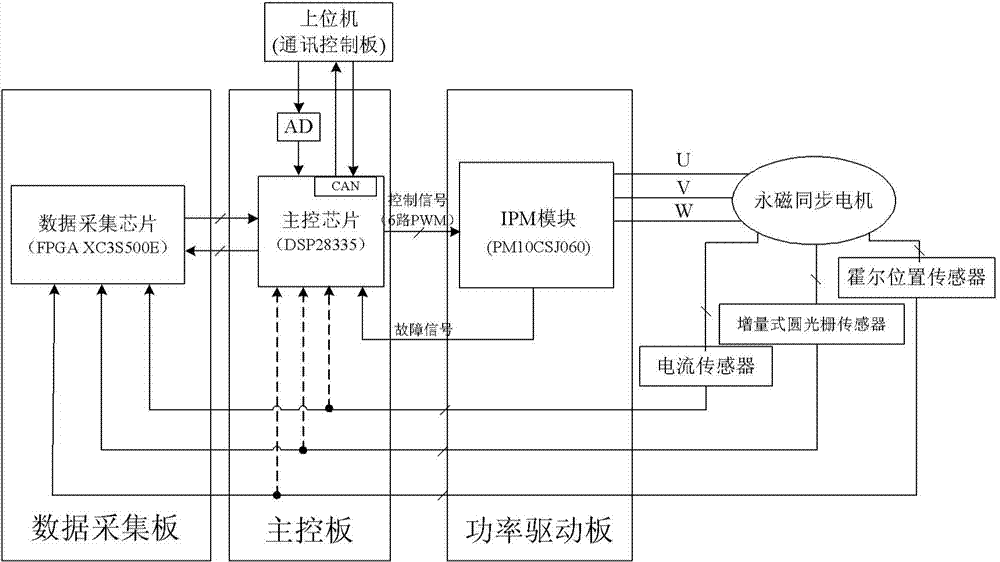

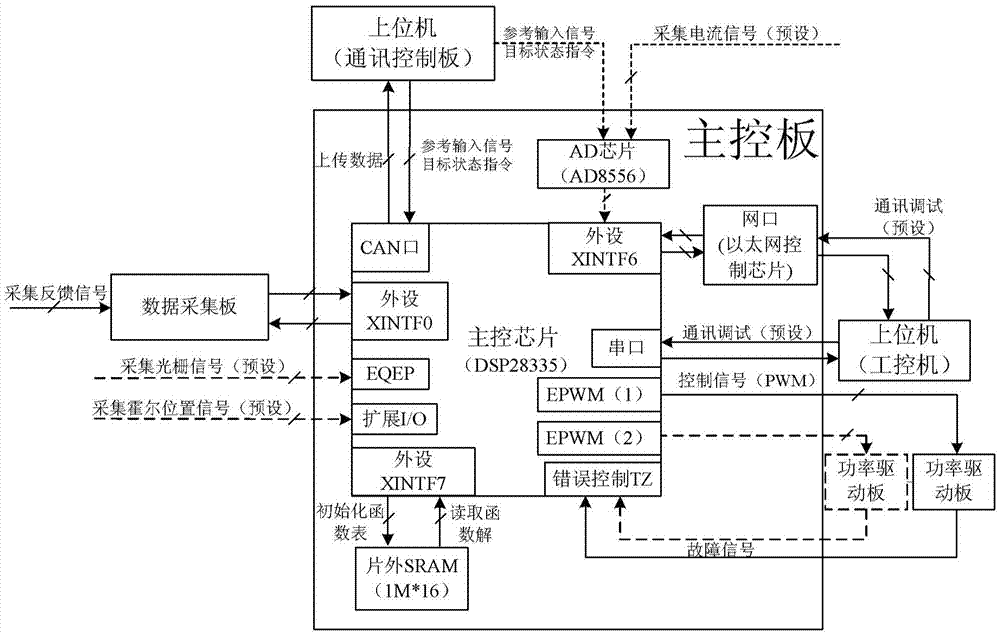

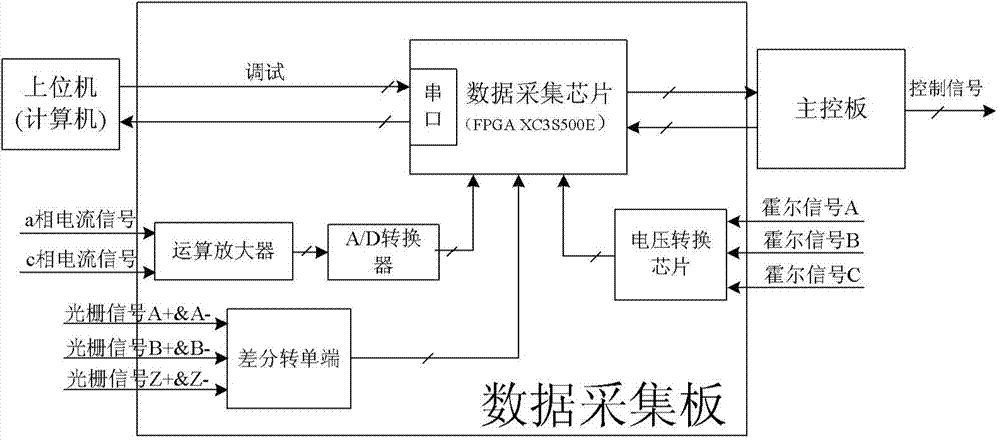

[0030] figure 1 It is a structural schematic diagram of the drive control circuit used in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com