Oil pumping unit control and heating integrated system

An integrated system and pumping unit technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of poor power supply quality, large voltage fluctuations, and shortened equipment life for well groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the devices used in the specific embodiments are all commercially available, and the connection and use methods are suggested by the manufacturer's instructions.

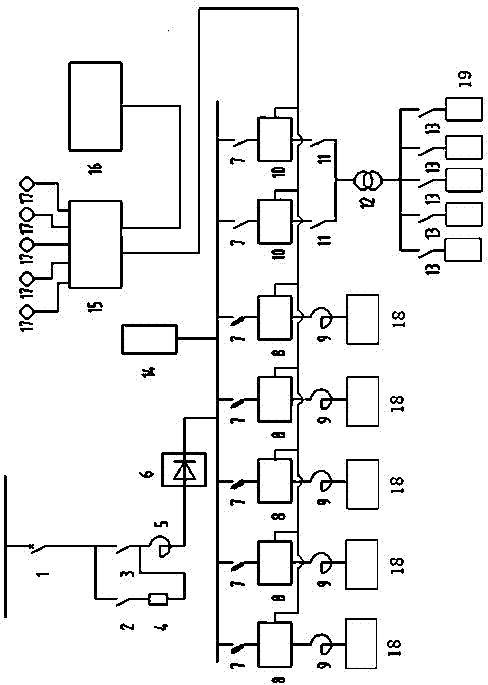

[0012] like figure 1 As shown, the present invention includes a power supply, a common DC bus, an inverter 8, an intermediate frequency power supply 10, a feedback unit 14, a PLC (programmable logic controller) 15, a human machine interface (Human Machine Interaction, referred to as HMI) 16, and a sensor 17 , pumping unit 18 and heating device 19, the power supply is connected with the public DC bus, the public DC bus is connected with the 5 inverters 8, the 2 intermediate frequency power supplies 10, and the 5 inverters 8 is connected to the five pumping units 18, the two intermediate frequency power supplies 10 are connected to the five heating devices 19, the common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com